bugsntinas

New Member

- Messages

- 27

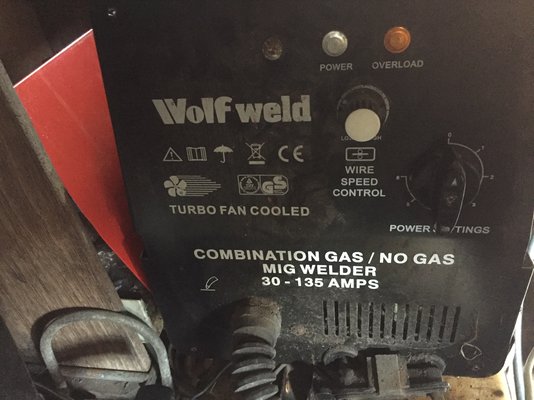

what is or is there any difference between these new inverter type welders over my old clockwork type? i just been told it is going to cost 100 euro to replace the main switch on mine with a second hand switch or 200 euro for a new one. i found a cheap gasless welder on ebay ya know the same design but different name type for £80 so thinking get one of them as if i replace my main switch something else could go wrong.

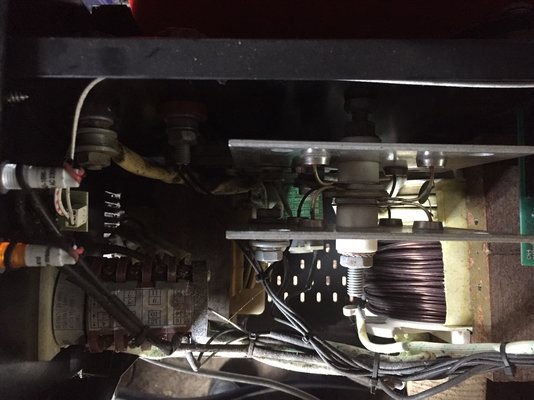

this is mine

this is mine

Have you a link to the machine you're considering? As sure as a cat's a hairy beast it'll be one of the generic Chinese ones, all much of a muchness with zero or very little backup [even under warranty which will undoubtedly say "Buyer to pay return postage"

Have you a link to the machine you're considering? As sure as a cat's a hairy beast it'll be one of the generic Chinese ones, all much of a muchness with zero or very little backup [even under warranty which will undoubtedly say "Buyer to pay return postage"  , so not worth claiming].

, so not worth claiming].