Multiwelder

New Member

- Messages

- 22

- Location

- Portugal

Hi

I'm new here and already need help.

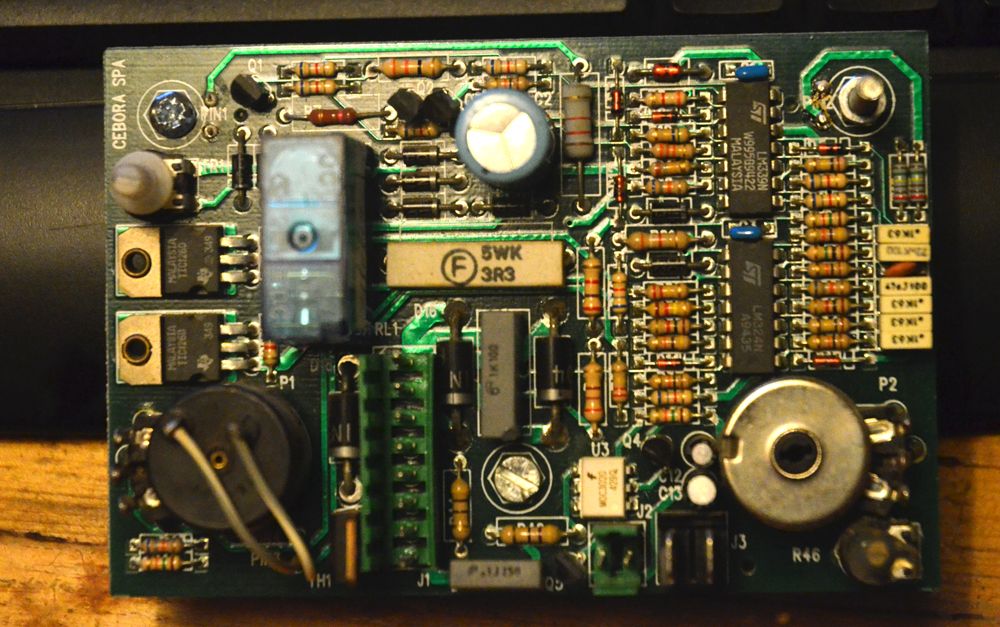

My old Cebora 170 has been having PCB problems.I had it repaired twice but it still comes back faulty.The problem is that they're not available new any more.

I've been thinking,these are fairly simple machines,couldn't I fit a DC motor speed control, a couple of relays for the contactor and gas solenoid valve just to get the thing going?

I believe the motor is 27v DC and the contactor is 230V.The Gas solenoid valve is 27V ac.It seems a shame to throw the welder away although my new inverter machine is a gem!

My knowledge of electronics is zero by the way.

Thanks in advance.

I'm new here and already need help.

My old Cebora 170 has been having PCB problems.I had it repaired twice but it still comes back faulty.The problem is that they're not available new any more.

I've been thinking,these are fairly simple machines,couldn't I fit a DC motor speed control, a couple of relays for the contactor and gas solenoid valve just to get the thing going?

I believe the motor is 27v DC and the contactor is 230V.The Gas solenoid valve is 27V ac.It seems a shame to throw the welder away although my new inverter machine is a gem!

My knowledge of electronics is zero by the way.

Thanks in advance.