Pete.

Member

- Messages

- 14,142

- Location

- Kent, UK

I have two machines (surface grinder and cylindrical grinder) that are fitted with grease nipples except the machines are meant to be lubricated with oil not grease. I had an ancient Tecalmit grease gun with a cast bronze head and more importantly a filler spout so I decided to see if I could convert it to an oil gun. Mostly this involves sealing the gun so that the oil stays inside.

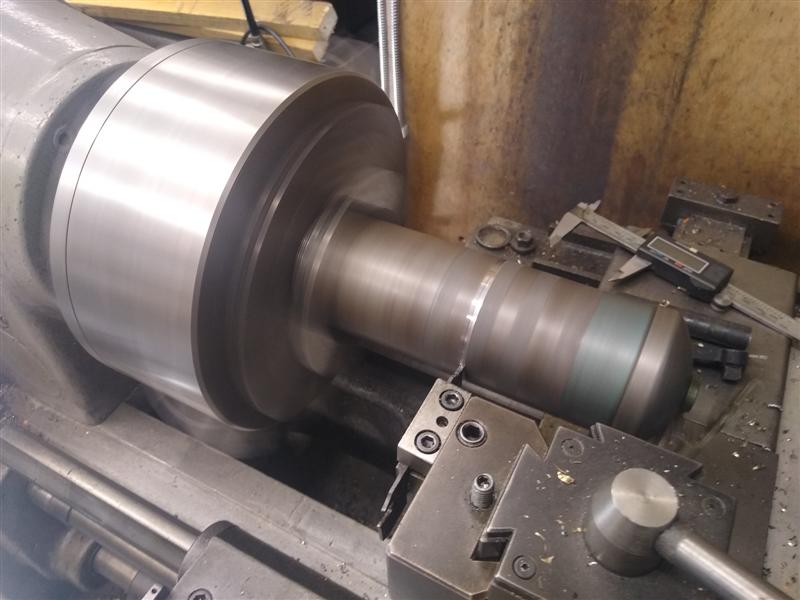

I didn't need the full capacity and wanted it to stand up so I cut the canister down by parting in the lathe.

After that I turned a heavy base from steel for a tight fit in the end of the shortened canister

Then I tig welded that all around and cleaned the weld up in the lathe. Now the oil gun can stand on it's own base no matter how full or empty it is.

I bent some flat bar as a handle and welded it to the can, cut the original grease gun handle down to length and threaded the pickup hole so I could screw in a bit of plastic pipe.

I had to prime it for the first try but once primed I found that it would draw oil up the pipe any time afterwards. It works just fine as you can see by the mess it made on my bench.

So here it is. I have to get a new delivery hose now to finish it off. This old one works but it's a bit leaky when pumping into a nipple

I didn't need the full capacity and wanted it to stand up so I cut the canister down by parting in the lathe.

After that I turned a heavy base from steel for a tight fit in the end of the shortened canister

Then I tig welded that all around and cleaned the weld up in the lathe. Now the oil gun can stand on it's own base no matter how full or empty it is.

I bent some flat bar as a handle and welded it to the can, cut the original grease gun handle down to length and threaded the pickup hole so I could screw in a bit of plastic pipe.

I had to prime it for the first try but once primed I found that it would draw oil up the pipe any time afterwards. It works just fine as you can see by the mess it made on my bench.

So here it is. I have to get a new delivery hose now to finish it off. This old one works but it's a bit leaky when pumping into a nipple