daedalusminos

Member

- Messages

- 2,429

- Location

- Norwich

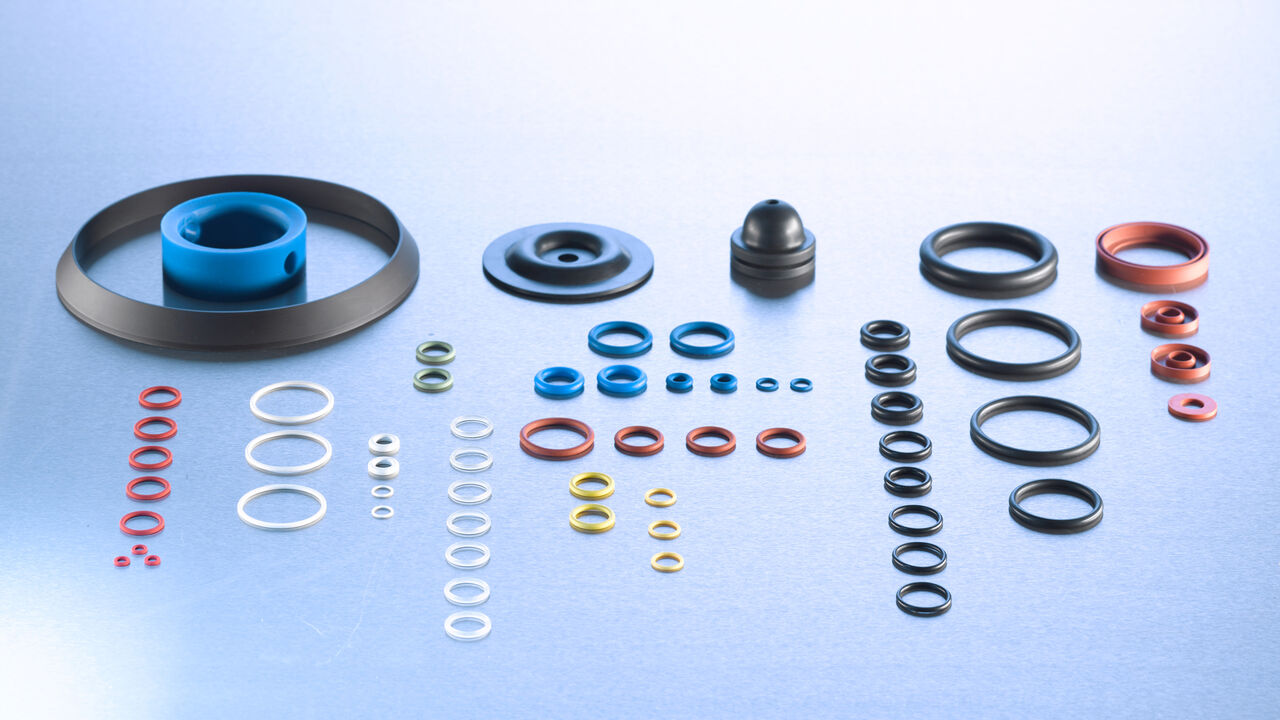

But your groove is only 1.4mm wide, are you sure this wasn't originally fitted with a lip seal or similar?So maybe a thicker o ring is required.

But your groove is only 1.4mm wide, are you sure this wasn't originally fitted with a lip seal or similar?So maybe a thicker o ring is required.

I think this could be the problem. A 1.5mm cross section o ring in a 1.55mm groove! So maybe a thicker o ring is required.

most are standard,Isn't it the case that quite a lot of O rings (by no means all) are specific sizes to the manufacturer / application? It discourages "un-authorised tampering".

Unlikely I would have thought - so many standard ones available, there'll be something out there close enough to work, so not worth the bother.Isn't it the case that quite a lot of O rings (by no means all) are specific sizes to the manufacturer / application? It discourages "un-authorised tampering".

. . . we have some large diameter ones made with a smaller section than you would expect - we often use them to close gaps on rotating manifolds where don't want a true seal, or to have components rubbing too close - the o-ring either takes a set, or wears enough to not wear the components running past it.

. . . we have some large diameter ones made with a smaller section than you would expect - we often use them to close gaps on rotating manifolds where don't want a true seal, or to have components rubbing too close - the o-ring either takes a set, or wears enough to not wear the components running past it.