You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

no rods

- Thread starter Bsmith

- Start date

- Messages

- 17,675

Is this a trick question?

Seriously, if the fit-up is good then you can do autogenous welds, if not then you could use mig wire.

Grab some lengths and twist them together using a drill. 2x = 1.6mm, 3x = 2.4mm etc.

It's not ideal but apparently it works.

Seriously, if the fit-up is good then you can do autogenous welds, if not then you could use mig wire.

Grab some lengths and twist them together using a drill. 2x = 1.6mm, 3x = 2.4mm etc.

It's not ideal but apparently it works.

I am using tig rods and managing not too badly but when I tryed autogenous with butt I burned holes through both tight fitting edges, with overlap the upper edge burned away before the base was melting, with fillet I burned holes though the upright.

- Messages

- 17,675

Ah, I misunderstood. I thought you'd run out of rods and hoped to carry on.

Autogenous welding relies on the fit-up being pretty much perfect, any slight defects will have a detrimental effect on the welds.

It's over to the tig boys on this one, someone like Tig Paul, Runnach or Hotrodder would be best to advise.

(Apologies to anyone else I forgot )

)

You should post some pics of your attempts, it will definitely help diagnose the problem.

Autogenous welding relies on the fit-up being pretty much perfect, any slight defects will have a detrimental effect on the welds.

It's over to the tig boys on this one, someone like Tig Paul, Runnach or Hotrodder would be best to advise.

(Apologies to anyone else I forgot

)

)You should post some pics of your attempts, it will definitely help diagnose the problem.

Paul.

Moderator

- Messages

- 7,010

- Location

- Northampton. UK

For autogenous tig as, woz said joint fit up is everything, you will need a sharp electrode, like a pencil point, sometimes establishing a pool can be difficult, and a touch with a fine filler rod, (mig wire is ideal) at the start can help to bridge the joint, without knowing more about what you are doing its difficult to give specific advice on tungsten size, amps etc, generally a lower torch angle helps to push the pool along, I tend to run the amps a bit high and keep a very short arc. that is a personal preference though, and does depend on the joint and material.

I am using tig rods and managing not too badly but when I tryed autogenous with butt I burned holes through both tight fitting edges, with overlap the upper edge burned away before the base was melting, with fillet I burned holes though the upright.

Thanks guys, the above were a memory of my results a couple of months back. I will try tig again soon and post some pics of my messy welds.

- Messages

- 13,495

- Location

- England

Its effective on stainless steel. As mentioned, the fit up needs to be good, virtually perfect, and no preps required, or you will end up with a sunken joint. Often a tiny drop of filler rod is required just to get the joint initially bridged.

Put the bits together and melt them to each other. With smooth weave patterns, its possible to make some very smart looking joins.

Give it a go. Aluminium isnt suitable to weld autogeneously.

Turn your amps down quite a bit, sounds like you are practicing on very thin material?

Normally when you add rod to the pool, it cools it slightly, hence the need to reduce amps. The other thing, is your tungsten sharpened properly? Putting a bit more of a point on it should make it slightly easier to control. The sharper point will give a tighter arc.

Put the bits together and melt them to each other. With smooth weave patterns, its possible to make some very smart looking joins.

Give it a go. Aluminium isnt suitable to weld autogeneously.

Turn your amps down quite a bit, sounds like you are practicing on very thin material?

Normally when you add rod to the pool, it cools it slightly, hence the need to reduce amps. The other thing, is your tungsten sharpened properly? Putting a bit more of a point on it should make it slightly easier to control. The sharper point will give a tighter arc.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,866

- Location

- East Yorkshire

As Hitch and TIG Paul have said fit up is King. Outside Corners in SS in is easiest, one to master. A lap joint needs to be tight up or the SS will warp and then you have no chance.

I do a LOT of .9mm SS and use 18-30 amps dependant on joint type. 1.6mm Red with a good sharp piont, a gas lens helps as well. 15cfm of gas.

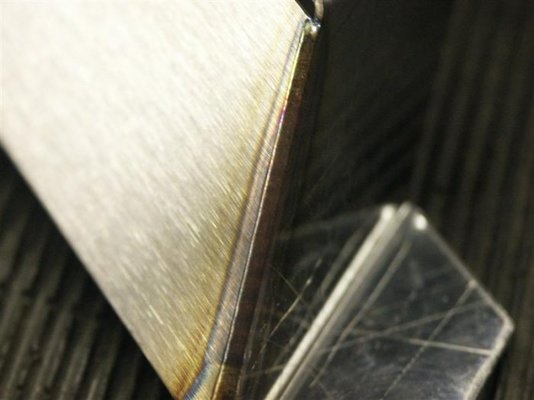

1st pic is a corner butt

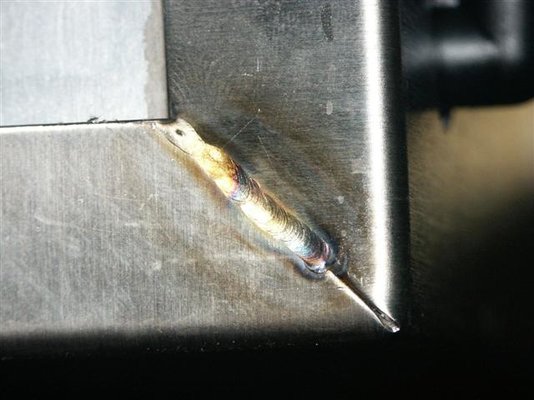

2nd a lap

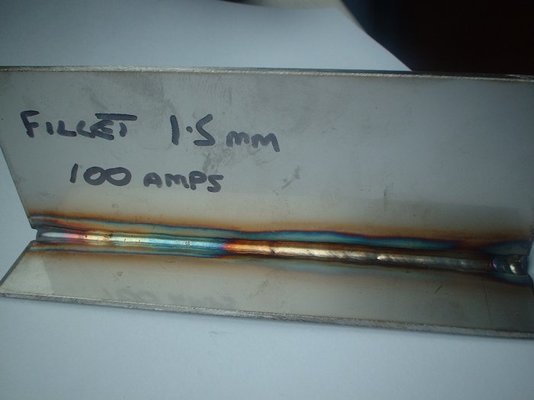

3rd straight butt

I do a LOT of .9mm SS and use 18-30 amps dependant on joint type. 1.6mm Red with a good sharp piont, a gas lens helps as well. 15cfm of gas.

1st pic is a corner butt

2nd a lap

3rd straight butt

Hard to say without watching you weld, and some very good advice from the others. Also, I'd be willing to bet money that your arc length is too long, if you are welding without filler, it really needs to be short (2mm or less if you can), try sticking your tungsten out a bit further, especially with the fillet, so that it gets right into the corner.

My welding is not that great, it does the job but I can but weld 0.8mm. I find eather turn the amps down a little or work closer, less gap. Always have some mig welding wire to hand. I bought a large real for about £12 ( I do get staff trade through family mind ) That will last a very long time though now. Apart from that I keep some 1mm stainless rods, also some 2.4 ish mm mild rods. Ive almost ran out of rods mind because im skint. Carnt see many home users needing any more than that.

Paul.

Moderator

- Messages

- 7,010

- Location

- Northampton. UK

Heres a couple of stainless examples, the lap is a piece of 3mm angle welded to a 1.5mm sheet, about 120 amps run it hot and fast to keep the heat input down and reduce distortion, same with the tee fillet, but at about 100 amps,

1.6 thoriated tungsten ground to a sharp point, 6lpm gas

1.6 thoriated tungsten ground to a sharp point, 6lpm gas

Bought a IFL 200PHF mainly because I prefer DC for mma but since it had all the crow for tig I fancied a go. Got a Y size cylinder of BOC Argon and set it all up some time back. I had another go today at tig, found that the HF start no longer works  I had to use lift start and my auto helmet is staying dark all the time

I had to use lift start and my auto helmet is staying dark all the time

Anyone know whats wrong with them plz? I will write more about the pics in the next reply.

Anyone know whats wrong with them plz? I will write more about the pics in the next reply.

I had to use lift start and my auto helmet is staying dark all the time

I had to use lift start and my auto helmet is staying dark all the time

Anyone know whats wrong with them plz? I will write more about the pics in the next reply.

Anyone know whats wrong with them plz? I will write more about the pics in the next reply.1st pic, attempt to autogenous lap .6mm thick S/S, all warped and lap burned away

2nd pic attempt to autogenous lap 1.2mm thick S/S lap also burned back.

3rd pic better autogenous results with 3mm thick mild steel (Sorry about bad pic)

4th pic autogenous butt, weld sunk.

5th pic Pieces of S/S pipe 4mm thick in fillet tigged with 3.2mm 316 S/S filler rod. I know the upright is undercut and think I can deal with that, but why are the welds all dull and greyish unlike yours which are all shiney and lovely colours?

2nd pic attempt to autogenous lap 1.2mm thick S/S lap also burned back.

3rd pic better autogenous results with 3mm thick mild steel (Sorry about bad pic)

4th pic autogenous butt, weld sunk.

5th pic Pieces of S/S pipe 4mm thick in fillet tigged with 3.2mm 316 S/S filler rod. I know the upright is undercut and think I can deal with that, but why are the welds all dull and greyish unlike yours which are all shiney and lovely colours?

Paul.

Moderator

- Messages

- 7,010

- Location

- Northampton. UK

I would say that you have a gas problem there, look at the scale on the surface, some of it is probably coming from the material, but I reckon most is from the atmosphere, what gas flow are you using and have you checked it at the torch rather than just relying on what the reg says, 6 to 8 lpm should do it, a no 7 ceramic and a 1.6 tungsten would be about right.

mild steel wont be as clean looking as stainless but you should be able to improve on what you've done so far.

The stainless sample needs more cleaning, all that surface contamination will end up in the weld. 3.2 rod is pretty big for that size of joint, 1.6 would be more than enough, for a small neat fillet even 1mm, the thicker the rod the more current you need, also make sure that the hot end of the rod stays in the gas shield, if you pull a red hot end out from the shield it will oxidize, then next time you dip you pass that oxidation straight into the pool

mild steel wont be as clean looking as stainless but you should be able to improve on what you've done so far.

The stainless sample needs more cleaning, all that surface contamination will end up in the weld. 3.2 rod is pretty big for that size of joint, 1.6 would be more than enough, for a small neat fillet even 1mm, the thicker the rod the more current you need, also make sure that the hot end of the rod stays in the gas shield, if you pull a red hot end out from the shield it will oxidize, then next time you dip you pass that oxidation straight into the pool

Paul.

Moderator

- Messages

- 7,010

- Location

- Northampton. UK

Those welds are without any filler at all, in fact I did the fillet this morning especially for this thread, the bracket is part of a job that I happened to be making this morning, its a guard for a food conveyor, its was done without filler just to seal the edges, they don't like too many crevices in the food industry, so autogenous welding is a useful technique to master. here's the complete thing.

Last edited:

Can you post a pic of a used tungsten (preferably in focus! ). Are you sure you've got PURE argon and no leaks in the system? The 'soot' around the welds is fairly typical of a contaminated tungsten, the amount of it typical with an argon/CO2 mix. Simple test would be to do a spot weld on a piece of stainless (not too thin or back it up by clamping it to a chunk of ally or something if no choice)- form a puddle, shut off the arc and pause over the weld for 4 or 5 secs for the post flow. The spot weld should be totally free of colour i.e. like a spot of freshly polished stainless

). Are you sure you've got PURE argon and no leaks in the system? The 'soot' around the welds is fairly typical of a contaminated tungsten, the amount of it typical with an argon/CO2 mix. Simple test would be to do a spot weld on a piece of stainless (not too thin or back it up by clamping it to a chunk of ally or something if no choice)- form a puddle, shut off the arc and pause over the weld for 4 or 5 secs for the post flow. The spot weld should be totally free of colour i.e. like a spot of freshly polished stainless

When welding is it virtually silent or is the pool spitting and hissing? Welding with DC TIG should be silent save background noise (welders fan/watercooler/stereo etc)

As said (of the common metals) only stainless is really suitable for autogenous welding, many aluminium alloys will crack and carbon steel often suffers with porosity unless filler is used

). Are you sure you've got PURE argon and no leaks in the system? The 'soot' around the welds is fairly typical of a contaminated tungsten, the amount of it typical with an argon/CO2 mix. Simple test would be to do a spot weld on a piece of stainless (not too thin or back it up by clamping it to a chunk of ally or something if no choice)- form a puddle, shut off the arc and pause over the weld for 4 or 5 secs for the post flow. The spot weld should be totally free of colour i.e. like a spot of freshly polished stainless

). Are you sure you've got PURE argon and no leaks in the system? The 'soot' around the welds is fairly typical of a contaminated tungsten, the amount of it typical with an argon/CO2 mix. Simple test would be to do a spot weld on a piece of stainless (not too thin or back it up by clamping it to a chunk of ally or something if no choice)- form a puddle, shut off the arc and pause over the weld for 4 or 5 secs for the post flow. The spot weld should be totally free of colour i.e. like a spot of freshly polished stainlessWhen welding is it virtually silent or is the pool spitting and hissing? Welding with DC TIG should be silent save background noise (welders fan/watercooler/stereo etc)

As said (of the common metals) only stainless is really suitable for autogenous welding, many aluminium alloys will crack and carbon steel often suffers with porosity unless filler is used