Ali

Member

- Messages

- 1,939

- Location

- Cheshire

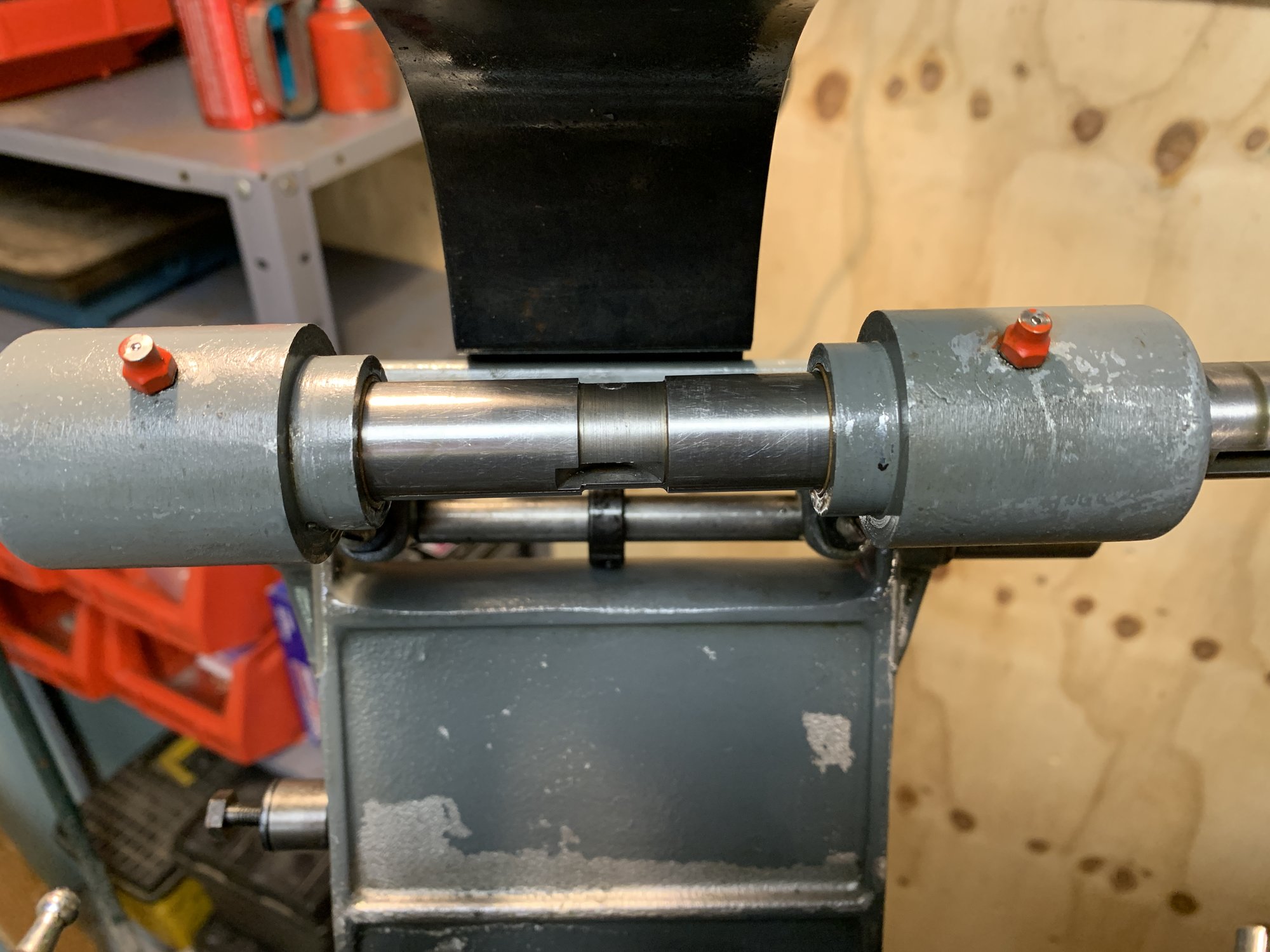

I’ve been giving the ML7 a bit of an overhaul and the ally swing head casting had quite a twist, due to bad adjustment (not sure if I’m the culprit or a previous owner as I’d never looked at it too closely - actually that statement probably makes me the culprit). You can see it in this photo:

It’s bad enough that it causes a few issues with aligning the pulleys.

So methinks, I’ll get a new one. Used may well be as bad or worse, but Myford are selling new castings so I ordered one. When it arrived, setting it down on a flat surface I noticed quite a wobble.

Well, it’s a casting so no reason to jump to conclusions but I looked a bit closer and took what measurements I could. Difficult to get any proper measurements because the bores for the countershaft are rough, to be reamed for the bushes, so I couldn’t fit a shaft to measure off without marking it so I’d be unable to return the part. Definitely off though.

The clutch shaft doesn’t have bushes and is roughly to size so I squeezed that in and it’s out of line with the other side

These holes aren’t machined after casting, but the fit was close enough that they should have been in better alignment.

So returned to Myford and they were very happy for me to return it but said it was the third one they’d accepted back. I asked if they would be able to check the others on the shelf but they admitted they wouldn’t know how to check if it was OK.

I don’t know whether telling them to put it on a flat surface like I did is a good test. Any other suggestions?

Another option I was considering is just asking them for a discount on the duff one* and then cutting it, making a jig up and having a highly skilled person (perhaps @doubleboost ?) weld it back together and maybe even beef it up.

*I’d rather not cut the one on the lathe, in case I need a backup.

Here’s a better photo of the offending part:

Ideas?

It’s bad enough that it causes a few issues with aligning the pulleys.

So methinks, I’ll get a new one. Used may well be as bad or worse, but Myford are selling new castings so I ordered one. When it arrived, setting it down on a flat surface I noticed quite a wobble.

Well, it’s a casting so no reason to jump to conclusions but I looked a bit closer and took what measurements I could. Difficult to get any proper measurements because the bores for the countershaft are rough, to be reamed for the bushes, so I couldn’t fit a shaft to measure off without marking it so I’d be unable to return the part. Definitely off though.

The clutch shaft doesn’t have bushes and is roughly to size so I squeezed that in and it’s out of line with the other side

These holes aren’t machined after casting, but the fit was close enough that they should have been in better alignment.

So returned to Myford and they were very happy for me to return it but said it was the third one they’d accepted back. I asked if they would be able to check the others on the shelf but they admitted they wouldn’t know how to check if it was OK.

I don’t know whether telling them to put it on a flat surface like I did is a good test. Any other suggestions?

Another option I was considering is just asking them for a discount on the duff one* and then cutting it, making a jig up and having a highly skilled person (perhaps @doubleboost ?) weld it back together and maybe even beef it up.

*I’d rather not cut the one on the lathe, in case I need a backup.

Here’s a better photo of the offending part:

Ideas?

.

.  would take a decent size torch to do that as ally is a good conductor and can dissipate the heat

would take a decent size torch to do that as ally is a good conductor and can dissipate the heat