delcbr

Member

- Messages

- 50

I have a Clarke Mig welding machine 135TE Turbo and 0.6mm mild steel clarke welding wire. proper BOC Argoshield light.

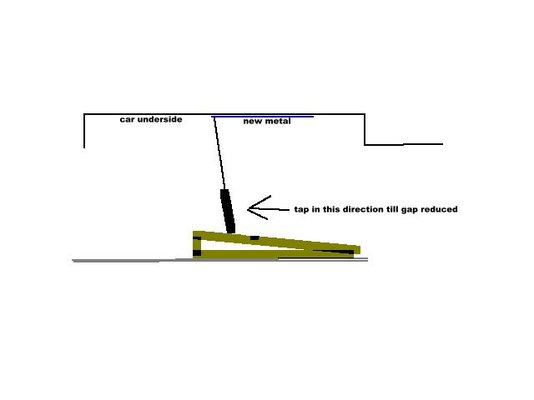

Whenever I am welding on my cars there can be a space between the new sheet I am placing on top of the original clean shiny metal as its difficult to get a new piece to contour exactly but its close.

So I use one hand to press new metal onto old where I am going to tack weld so there's no air gap and mig weld a tack to hold it not a lot of force is needed to hold in place but there is resistance of course I keep the pressure on it for a further 10 secs to allow it to hold.

But...after 20-60 secs of a single tack weld "ping"!!! and breaks the weld and doesn't hold!!!

Its so frustrating.

Where am I going wrong?

Whenever I am welding on my cars there can be a space between the new sheet I am placing on top of the original clean shiny metal as its difficult to get a new piece to contour exactly but its close.

So I use one hand to press new metal onto old where I am going to tack weld so there's no air gap and mig weld a tack to hold it not a lot of force is needed to hold in place but there is resistance of course I keep the pressure on it for a further 10 secs to allow it to hold.

But...after 20-60 secs of a single tack weld "ping"!!! and breaks the weld and doesn't hold!!!

Its so frustrating.

Where am I going wrong?