Tiggy_dorset

It looks just like a bought one!

- Messages

- 1,970

- Location

- Weymouth, Dorset, UK

My shiny new compressor has sat in my main shed for nearly 2 months. I have finally made some progress for building it a home.

Shed was bought from Tesco Online and took 3 hours to erect between 2 people. The patio has a run off and is not level, so I jacked the shed in each corner with stainless blocks to level it, then cemented the whole way round giving the shed a level base to sit on.

I then put down some wooden joists inside for the ply flooring to sit level on and something to bolt the compressor to. I also packed sound proofing between the joists (sample leaning up against the shed outside) before laying the floor down

Below are pics of the shed fully lined with the sound proofing/insulation, including ceiling and doors

Below is my shiny beast! It is now bolted down on original SIP anti-vibration rubber mounts.

It is now bolted down on original SIP anti-vibration rubber mounts.

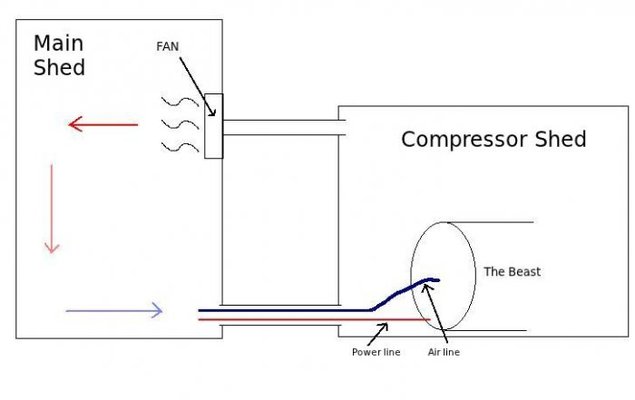

Next on the agenda is to install the tube linking the compressor shed to my main shed for the power and air line.

Shed was bought from Tesco Online and took 3 hours to erect between 2 people. The patio has a run off and is not level, so I jacked the shed in each corner with stainless blocks to level it, then cemented the whole way round giving the shed a level base to sit on.

I then put down some wooden joists inside for the ply flooring to sit level on and something to bolt the compressor to. I also packed sound proofing between the joists (sample leaning up against the shed outside) before laying the floor down

Below are pics of the shed fully lined with the sound proofing/insulation, including ceiling and doors

Below is my shiny beast!

It is now bolted down on original SIP anti-vibration rubber mounts.

It is now bolted down on original SIP anti-vibration rubber mounts.

Next on the agenda is to install the tube linking the compressor shed to my main shed for the power and air line.

Last edited:

and do you want a supply of nice warm air in the summer?

and do you want a supply of nice warm air in the summer? ) can come up with, design wise.

) can come up with, design wise.