harveyblades

New Member

- Messages

- 16

- Location

- cornwall uk

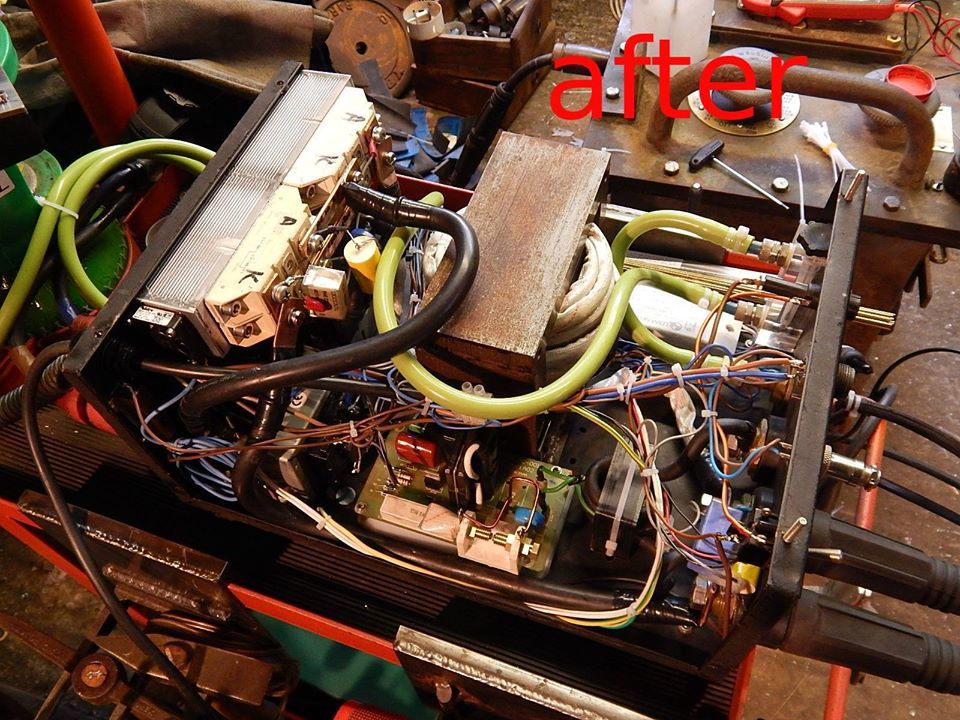

A few mods to a high frequency tig box. When I originally got it the High frequency part was a blob of snot glue with a transistor / transformer / spark plug etc. Not original. Didn't work very well. I replaced it with a unit from china.

Next up the inductor to smooth DC current. It wasn't doing much either so I took an old welding transformer and filled it with welding cable that I wrapped in fiberglass insulation. Much smoother and starts an arc easier.

Added some buttons to switch the contactor on and HF off for stick welding and HF / contactor control to the tig switch for tig.

The thermal cutoff was missing so I put the diodes on a diy heatsink and fan. I haven’t blown it up yet so assume it’s got 100% duty cycle now.

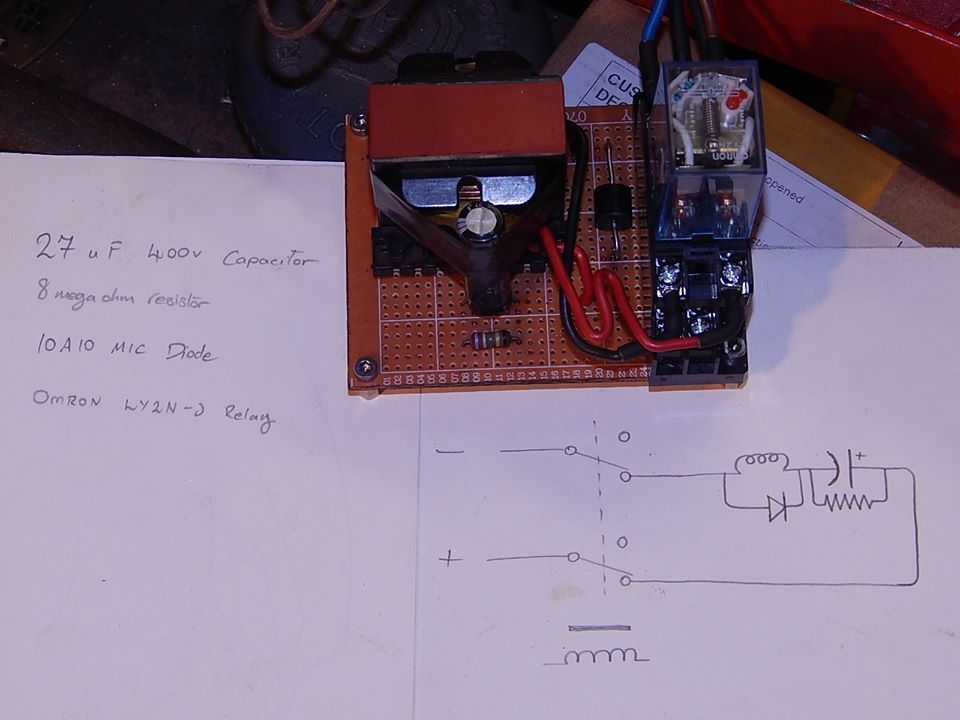

HF worked well at higher amperage but not low amperage. I don't own an oscilloscope so guessed what was wrong and made the board in the last image. Essentially a bandpass filter. Relay disconnects it once the arc is established. The HF seems to like clean DC and the capacitor allows a small discharge to get the arc going. HF works great now.

I found another large transformer at the scrap yard and plan to turn it into another inductor and add that soon. My HF assisting circuit may not be necessary then. If I were to do it all again I'd just build a HF box from scratch.