chrisg3103

Forum Supporter

- Messages

- 790

Thought this might be of interest, not seen any mention of the MPCNC on here but its pretty cool, and cheap!

The aim of this was to make a super cheap CNC plasma cutter, but things snowballed... adding up what i have spent, taking away the fails and fancy bits i recon you can have a functional CNC platform for £150, if you have a 3d printer. This is what i did with it:

first off this is the home of the MPCNC - https://www.v1engineering.com/

I started off just wanting a small scale dodad i could stash away when not needed, instead of having a dedicated table and whatnot, so set off calculating the maximum size i could make it from 2 x 3M lengths of conduit. Think it was about 720mm square with a working area just shy of 500mm square, there is a cut calculator available. I wont go too much into detail about the nuts and bolts as its done to death on youtube and the MPCNC forums.

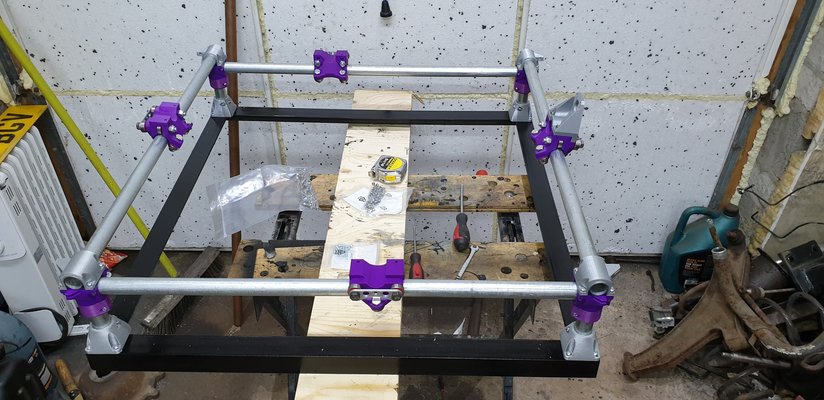

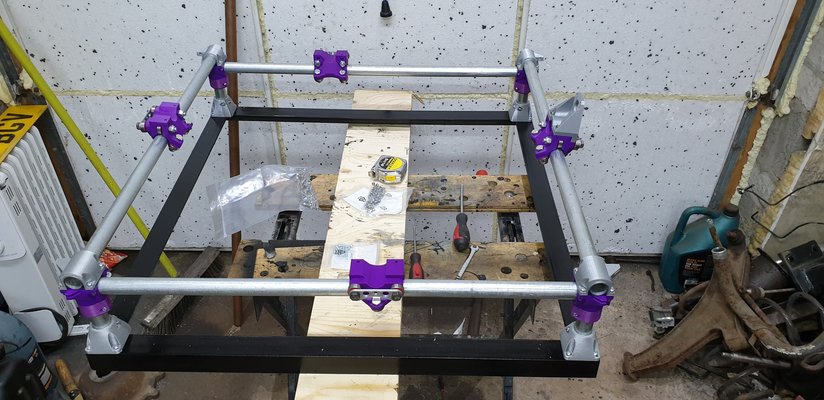

To try make my portable idea i first made an angle iron frame.

The parts will take many many days to print, and the best part of 2 spools of filament, you will end up with a pile of bits like so:

dosnt look like much but the tall parts in the top corner were 13 hours each!

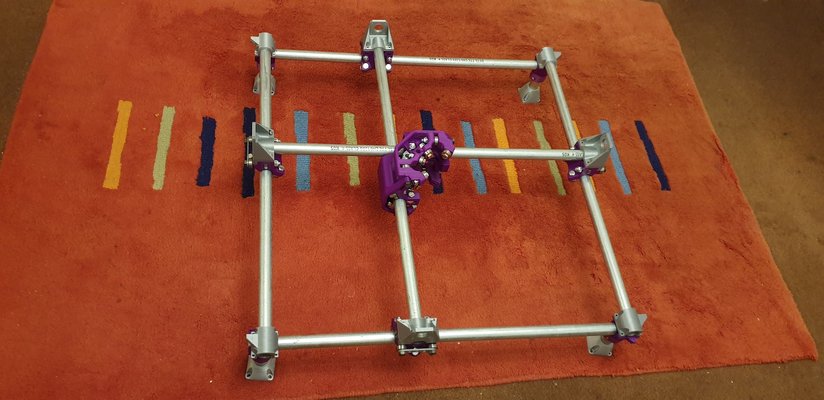

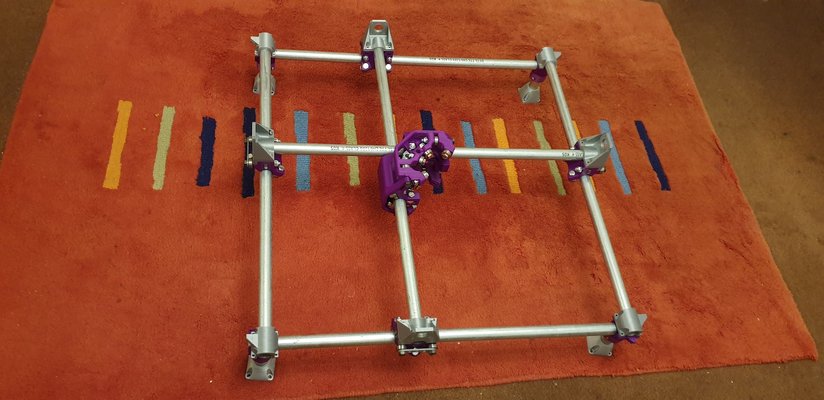

Quick mockup, just because.

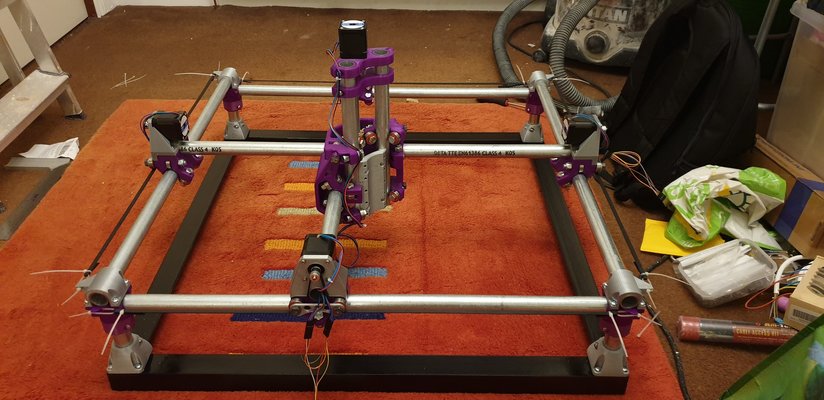

rails largley assembled, squared and bolted to the frame, all seems fairly rigid.

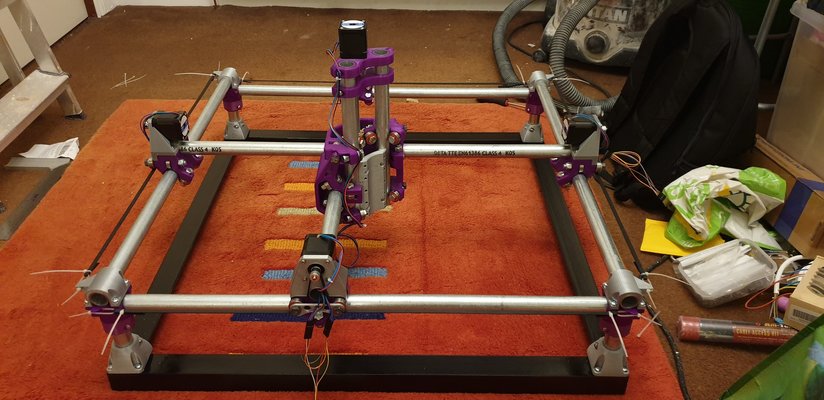

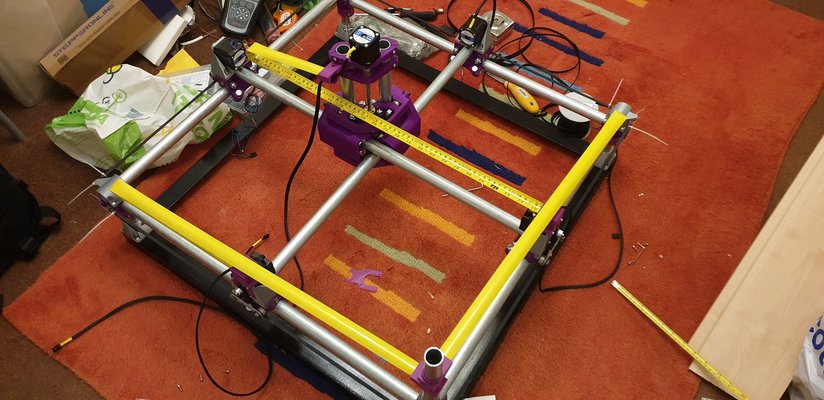

Moved inside, because its cold. This was first test fire of the cheapo ramps and motor drivers, a few teething issues having to install a usb driver onto the computer so the knockoff arduino would talk to it but got there in the end and got some movement.

Now this is where things took a turn for the more expensive, it started to look like a real thing so i started trying to improve it, mostly cable management. As it stood that would of worked fine as a machine, but i wanted a nice control box and stuff. so here is a cost breakdown for the base machine:

25mm conduit (from screwfix) - £21

PLA 2 spools - £30

steppers - £45

RAMPS stack, screen + drivers - £19.50

lead screw + nut - £7

60 Bearings - £12

Motor pulleys + belt - £9

coupler - £6

Ribbon cable - £4.50

Dupont connectors+tool - £20

So thats £174, but i included the cable and dupont connectors i used to extend the stepper wiring and make the splitters. If you have some of this stuff already all the better, or if you go a different route. Also some of the things can be found much cheaper, thats just what i paid for convenience, the curse of amazon prime... if your not so impatient and shop around you can save a few more £

More in pt 2

The aim of this was to make a super cheap CNC plasma cutter, but things snowballed... adding up what i have spent, taking away the fails and fancy bits i recon you can have a functional CNC platform for £150, if you have a 3d printer. This is what i did with it:

first off this is the home of the MPCNC - https://www.v1engineering.com/

I started off just wanting a small scale dodad i could stash away when not needed, instead of having a dedicated table and whatnot, so set off calculating the maximum size i could make it from 2 x 3M lengths of conduit. Think it was about 720mm square with a working area just shy of 500mm square, there is a cut calculator available. I wont go too much into detail about the nuts and bolts as its done to death on youtube and the MPCNC forums.

To try make my portable idea i first made an angle iron frame.

The parts will take many many days to print, and the best part of 2 spools of filament, you will end up with a pile of bits like so:

dosnt look like much but the tall parts in the top corner were 13 hours each!

Quick mockup, just because.

rails largley assembled, squared and bolted to the frame, all seems fairly rigid.

Moved inside, because its cold. This was first test fire of the cheapo ramps and motor drivers, a few teething issues having to install a usb driver onto the computer so the knockoff arduino would talk to it but got there in the end and got some movement.

Now this is where things took a turn for the more expensive, it started to look like a real thing so i started trying to improve it, mostly cable management. As it stood that would of worked fine as a machine, but i wanted a nice control box and stuff. so here is a cost breakdown for the base machine:

25mm conduit (from screwfix) - £21

PLA 2 spools - £30

steppers - £45

RAMPS stack, screen + drivers - £19.50

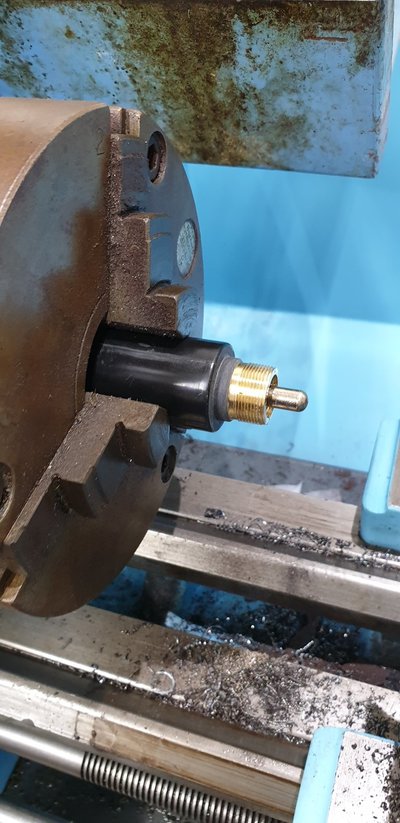

lead screw + nut - £7

60 Bearings - £12

Motor pulleys + belt - £9

coupler - £6

Ribbon cable - £4.50

Dupont connectors+tool - £20

So thats £174, but i included the cable and dupont connectors i used to extend the stepper wiring and make the splitters. If you have some of this stuff already all the better, or if you go a different route. Also some of the things can be found much cheaper, thats just what i paid for convenience, the curse of amazon prime... if your not so impatient and shop around you can save a few more £

More in pt 2

Seems the machine torch was behaving like the duff hand torch? it lost the arc halfway though the cut and that fizzing and popping is it trying to get going again, but that HF noise really screwed with the ramps and it reset, not so good

Seems the machine torch was behaving like the duff hand torch? it lost the arc halfway though the cut and that fizzing and popping is it trying to get going again, but that HF noise really screwed with the ramps and it reset, not so good

If you dont have a printer the anet is only about £110 or the ender £150

If you dont have a printer the anet is only about £110 or the ender £150