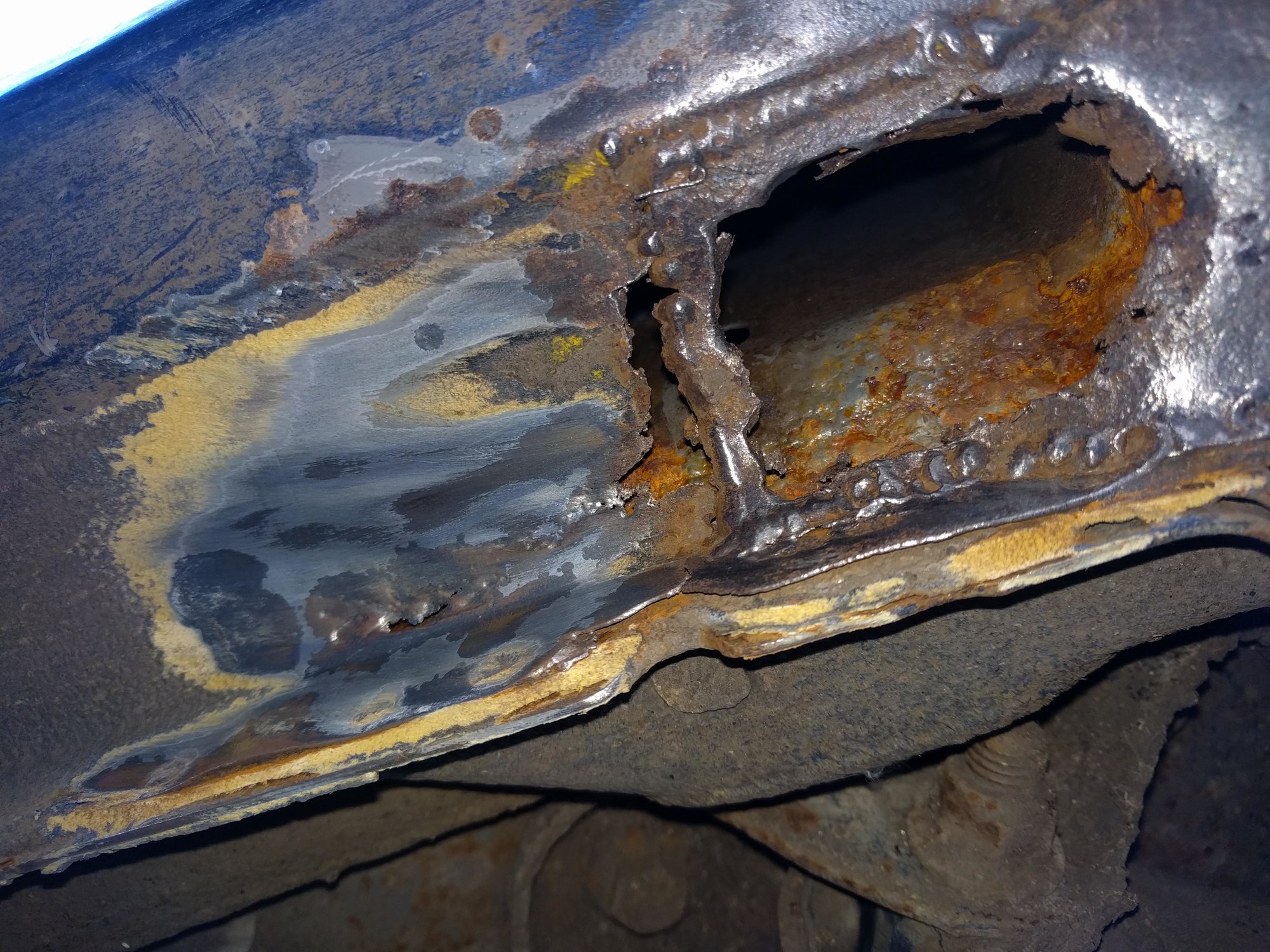

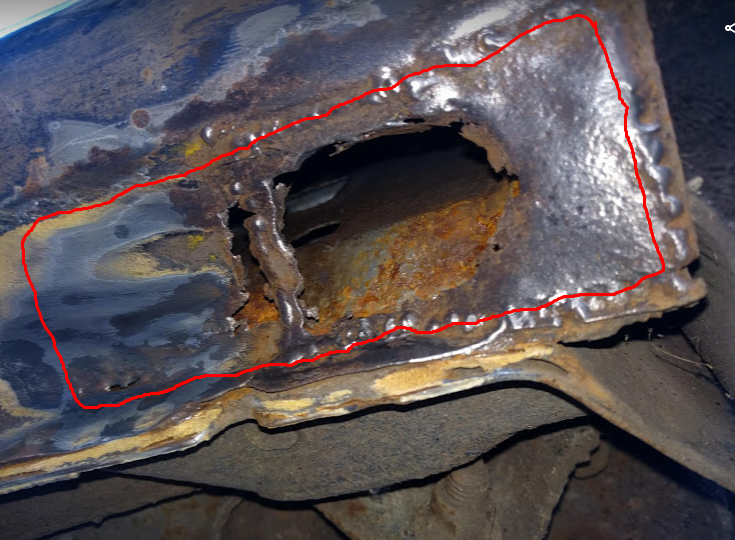

So my car failed on the sill having a hole in it. I'm after some advice on what I can\can't do as to repairing it. I'm thinking using some 1mm (could I use 2mm?) rectangular plate to fully cover the hole and then weld all the way round it totally sealing it up.

Was quite surprise to see that this area has been welded before!

I've taken a wire wheel to it to clean it up for your perusal.

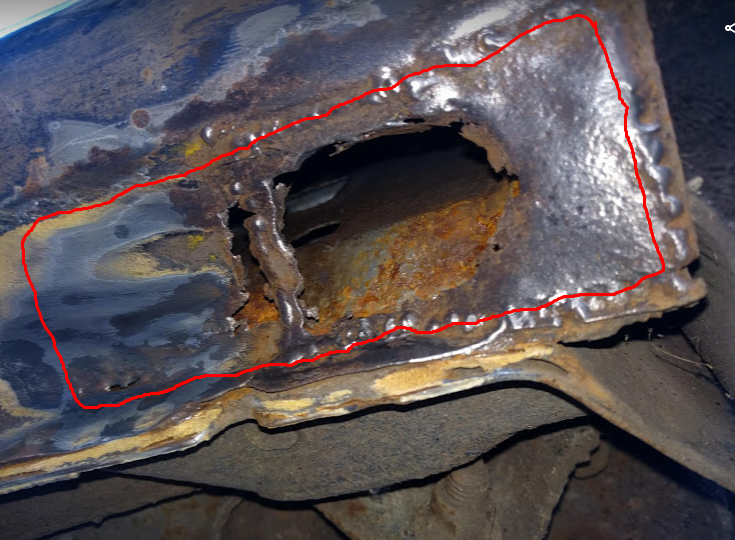

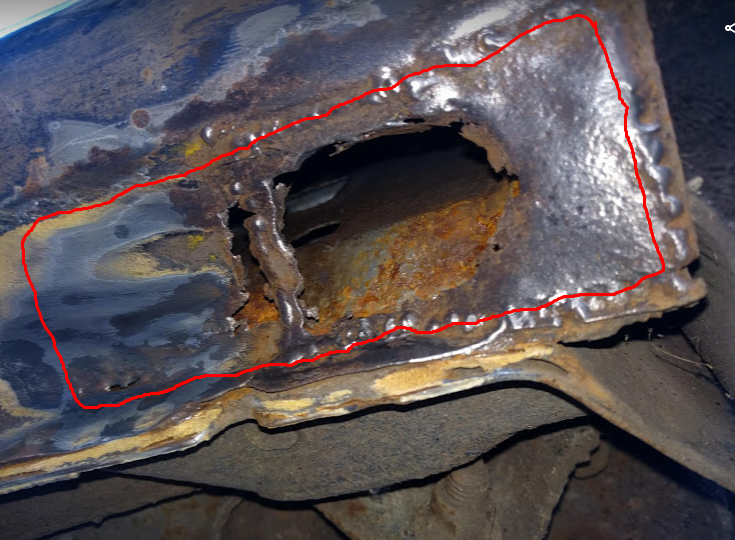

Does it have to be flush or can I lay the new plate on top of the hole and weld round it so its slightly raised? I have included a picture with a red line to show the size of the patch how I propose to cover

the hole.

the hole.

Any help appreciated.

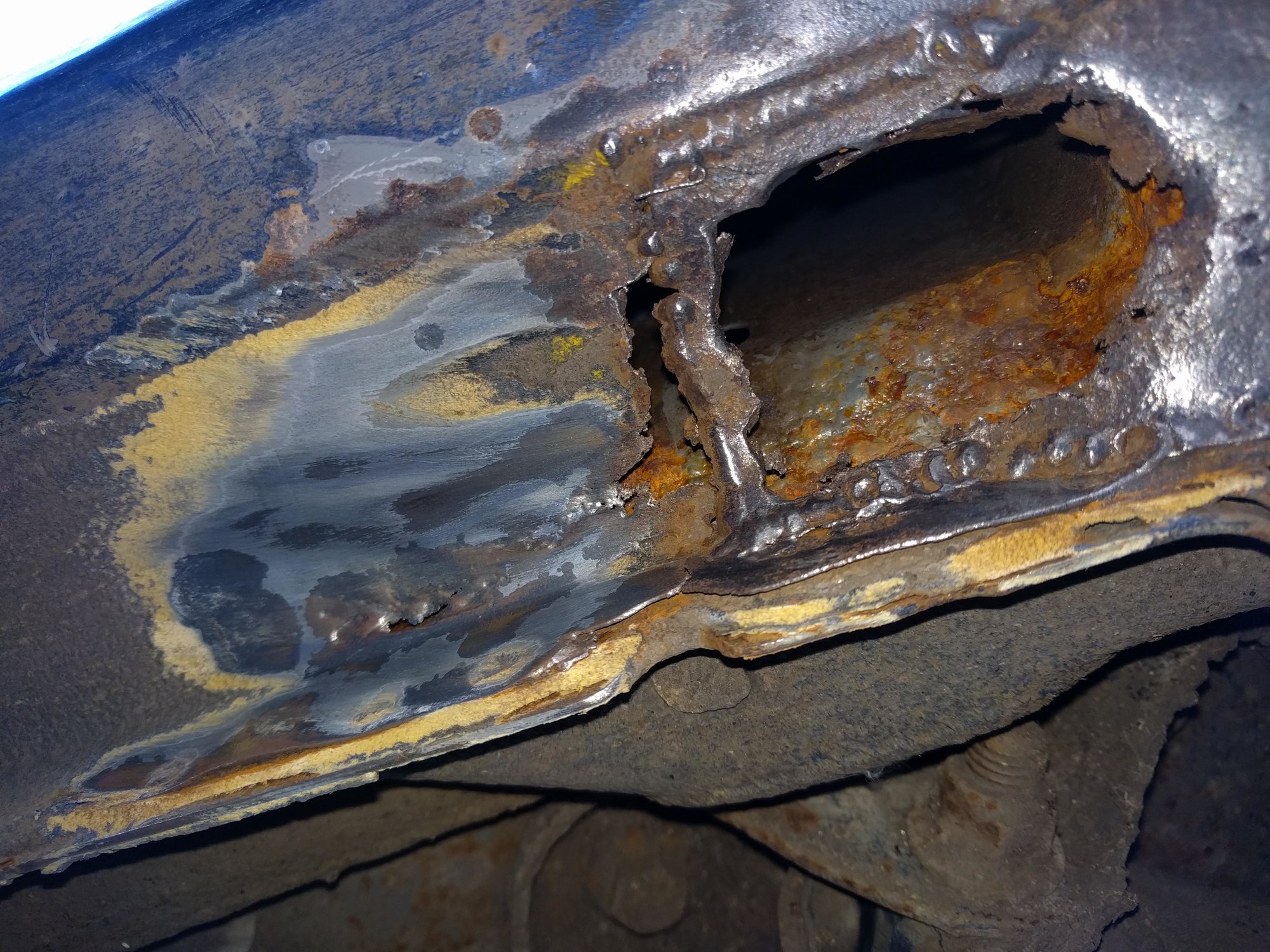

Was quite surprise to see that this area has been welded before!

I've taken a wire wheel to it to clean it up for your perusal.

Does it have to be flush or can I lay the new plate on top of the hole and weld round it so its slightly raised? I have included a picture with a red line to show the size of the patch how I propose to cover

Any help appreciated.