RaceDiagnostics

Forum Supporter

- Messages

- 2,915

Got a kind advisory (could have been a fail) at the MOT for floor pans. The problem is caused by a bracket spot welded to the underside used to attach the car to the original production line conveyor. Done with no thought of the potential for rust.

Right hand side.

Left.

The bracket.

Cut out.

There is a repair panel available at a £90 a side so I used a plain sheet instead costing a couple of pounds.

I didn't want to weld from above in case of spatter damage to the interior and access from below was very tight as I couldn't use my lift due to the location of the repair. So I decided to use an oversized patch and weld in from below.

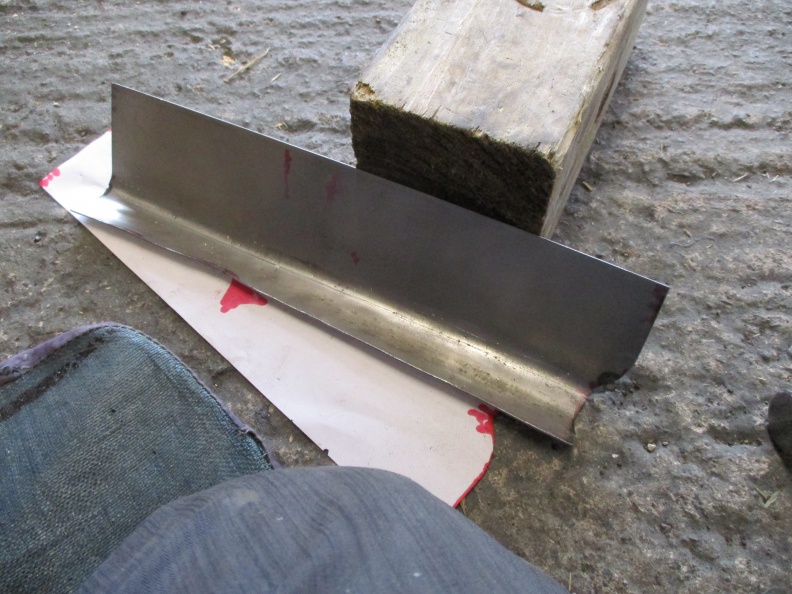

New patch

Welded in.

Other side from above.

Then painted with epoxy.

Then tiger seal in case of any pin holes.

And finally rubber underseal.

There was a debate recently about butt or joddled repairs, I normally butt welds but in this case as access from below was restricted so I decided to use a joddled repair since there was also no problem to seal the flanged side.

Right hand side.

Left.

The bracket.

Cut out.

There is a repair panel available at a £90 a side so I used a plain sheet instead costing a couple of pounds.

I didn't want to weld from above in case of spatter damage to the interior and access from below was very tight as I couldn't use my lift due to the location of the repair. So I decided to use an oversized patch and weld in from below.

New patch

Welded in.

Other side from above.

Then painted with epoxy.

Then tiger seal in case of any pin holes.

And finally rubber underseal.

There was a debate recently about butt or joddled repairs, I normally butt welds but in this case as access from below was restricted so I decided to use a joddled repair since there was also no problem to seal the flanged side.