Hi Guys,

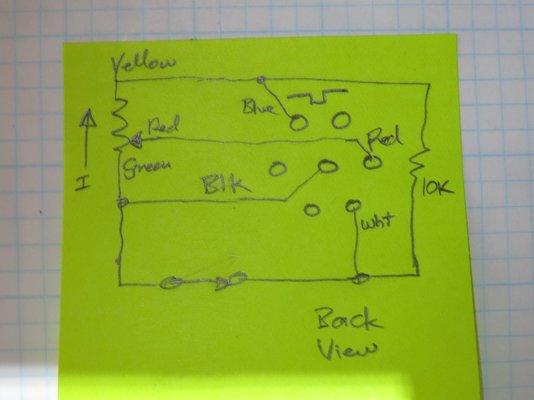

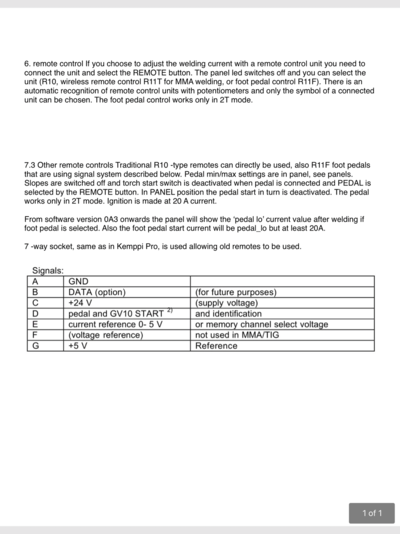

I have had all the wires cut on my torch and they are all black so no way to know how to reconnect.

The plug is a Mil spec with pins "lettered" from A to F.

It should be easy as there is only "on/off" and "power up/down" to connect.

Can anyone give me some simple instructions - i.e. A to B is on/off etc?

Thanks

Ben

I have had all the wires cut on my torch and they are all black so no way to know how to reconnect.

The plug is a Mil spec with pins "lettered" from A to F.

It should be easy as there is only "on/off" and "power up/down" to connect.

Can anyone give me some simple instructions - i.e. A to B is on/off etc?

Thanks

Ben