You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ML7 reversing switch

- Thread starter Ali

- Start date

Ali

Member

- Messages

- 1,939

- Location

- Cheshire

Ok re-wired and works fine (well,

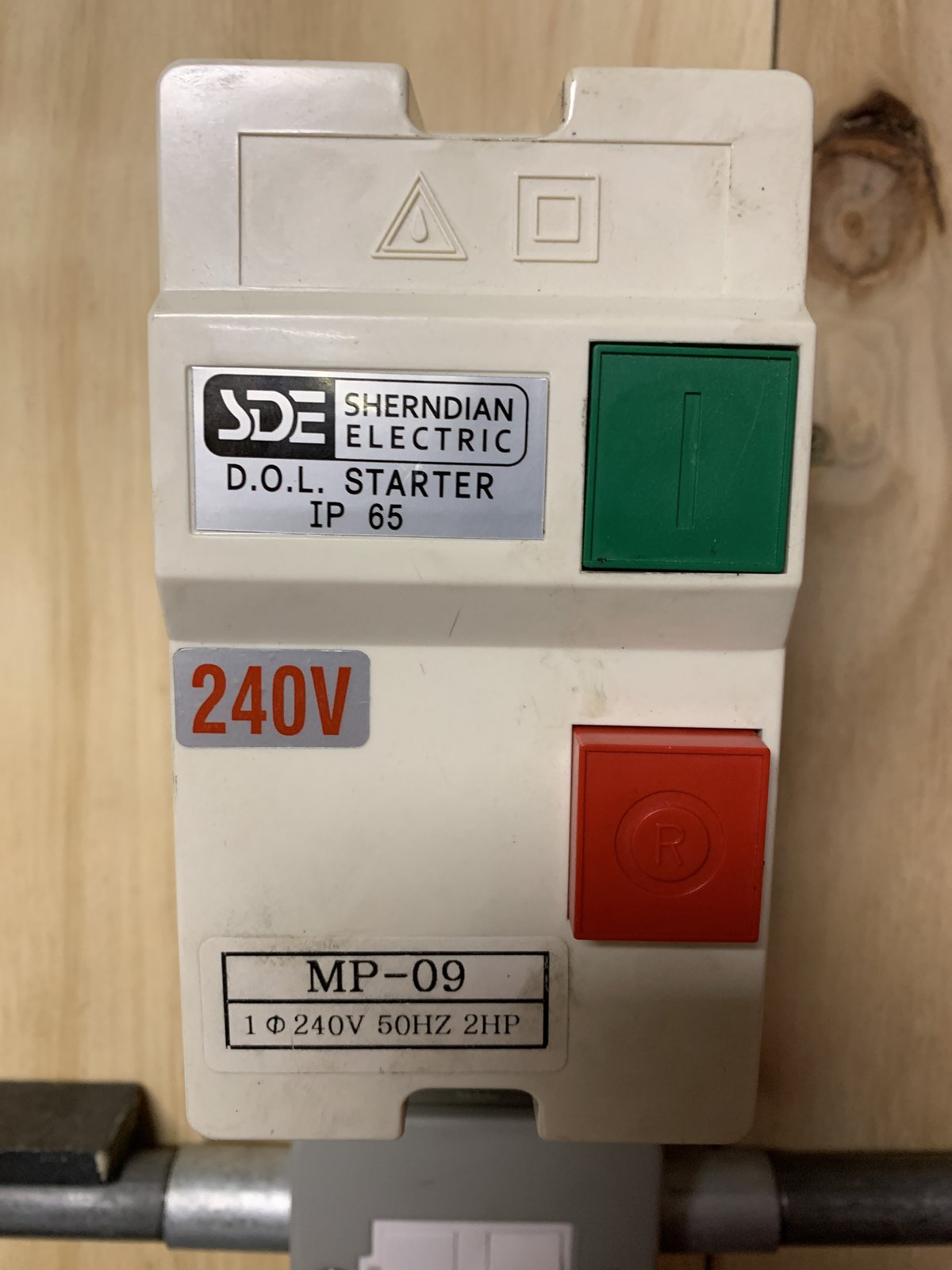

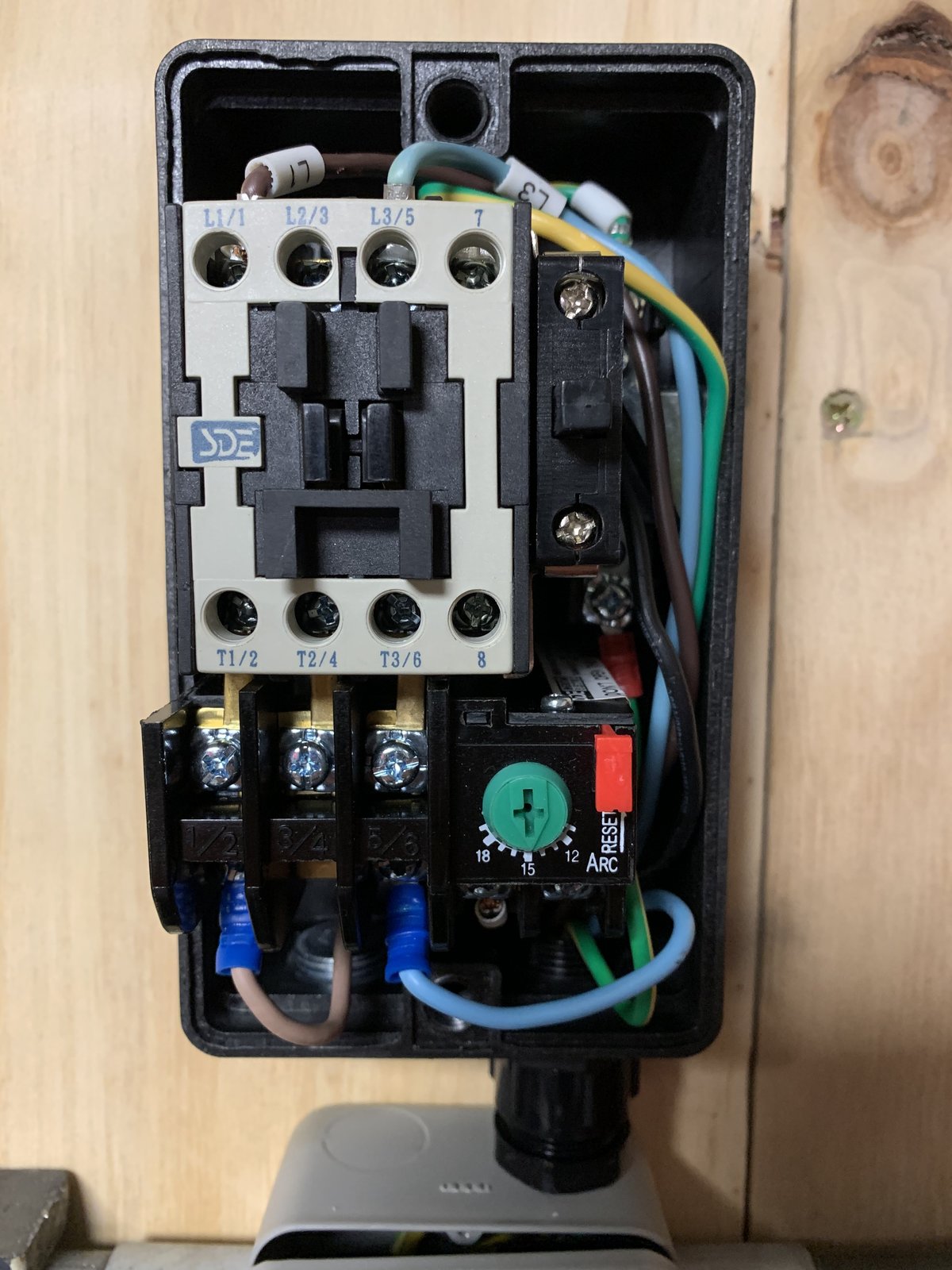

as fine as it was before) with the old starter on the bench. Fitted an NVR and the motor starts up, but slowly. No idea if this starter is suitable, it came off another machine.

I’m guessing the little green dial has something to do with it

I think the motor plate says 1/2 HP, but it’s taken a beating over the years

Clues?

as fine as it was before) with the old starter on the bench. Fitted an NVR and the motor starts up, but slowly. No idea if this starter is suitable, it came off another machine.

I’m guessing the little green dial has something to do with it

I think the motor plate says 1/2 HP, but it’s taken a beating over the years

Clues?

daleyd

Member

- Messages

- 10,483

- Location

- Wrexham, North Wales

Little dial is just an overload so doesn’t make any difference (it’s too big for that motor but no real matter).

Pushing the green button will just energise the contactor, there’s no time delay in those starters.

If connected direct to a plug does the motor still start slowly? I’d imagine yes, in which case possibly an over packed bearing or maybe that copper ring pushing against the cap too much. If neither of those then maybe centrifugal switch is playing up(I can’t see what type motor is, those older ones are quite often a split phase motor) or capacitor if it’s a cap start motor.

Pushing the green button will just energise the contactor, there’s no time delay in those starters.

If connected direct to a plug does the motor still start slowly? I’d imagine yes, in which case possibly an over packed bearing or maybe that copper ring pushing against the cap too much. If neither of those then maybe centrifugal switch is playing up(I can’t see what type motor is, those older ones are quite often a split phase motor) or capacitor if it’s a cap start motor.

Ali

Member

- Messages

- 1,939

- Location

- Cheshire

Best not to over pack that bearing, too much grease can lead to overheating and shorter life.

Little dial is just an overload so doesn’t make any difference (it’s too big for that motor but no real matter).

Pushing the green button will just energise the contactor, there’s no time delay in those starters.

If connected direct to a plug does the motor still start slowly? I’d imagine yes, in which case possibly an over packed bearing or maybe that copper ring pushing against the cap too much. If neither of those then maybe centrifugal switch is playing up(I can’t see what type motor is, those older ones are quite often a split phase motor) or capacitor if it’s a cap start motor.

The cap is still off the pulley end but I did grease the other end so will investigate that. To be honest a new set of bearings wouldn’t hurt, I need to order some. I’ll check the switch too. It did run fine with the old starter on the bench, but came apart after that for further fiddling.

daleyd

Member

- Messages

- 10,483

- Location

- Wrexham, North Wales

If it’s a split phase motor there is usually a centrifugal switch that disconnects the second phase when up to speed, on my Elliot drill that was all gunked up when I got it, after I cleaned it out it worked fine. (I don’t know if yours has one but worth a check). I seem to remember on mine it’s on the bearing end so I wonder if you may have inadvertently pushed some grease into it when greasing the bearing?

Ali

Member

- Messages

- 1,939

- Location

- Cheshire

If it’s a split phase motor there is usually a centrifugal switch that disconnects the second phase when up to speed, on my Elliot drill that was all gunked up when I got it, after I cleaned it out it worked fine. (I don’t know if yours has one but worth a check). I seem to remember on mine it’s on the bearing end so I wonder if you may have inadvertently pushed some grease into it when greasing the bearing?

Not entirely unlikely - I gave it all a good clean but it was fiddly to get back together. Will have another look tonight. Thanks for all the tips

Ali

Member

- Messages

- 1,939

- Location

- Cheshire

Quick update, I’ve just had 15 minutes to have a fiddle. It does seem the centrifugal switch doesn’t want to disengage. I wouldn’t say it’s clean, but there’s no grease around it and it’s free to move by hand. I’d like to get it off for a proper look but can’t see how to remove it.

The other side of the switch with the copper ring and contacts looks at a glance like it could be slightly deformed, ie., one contact is closer than the other. Need to look closer at this.

I cleaned the grease out of the bearings and ran it without the caps on but this doesn’t make any difference, though I’ve ordered a new set anyway as they’re well past their best.

The other side of the switch with the copper ring and contacts looks at a glance like it could be slightly deformed, ie., one contact is closer than the other. Need to look closer at this.

I cleaned the grease out of the bearings and ran it without the caps on but this doesn’t make any difference, though I’ve ordered a new set anyway as they’re well past their best.

roofman

Purveyor of fine English buckets and mops

- Messages

- 13,153

- Location

- North West with water on 3 sides

I have motors..your welcome to have a sniff about and see if one will do youQuick update, I’ve just had 15 minutes to have a fiddle. It does seem the centrifugal switch doesn’t want to disengage. I wouldn’t say it’s clean, but there’s no grease around it and it’s free to move by hand. I’d like to get it off for a proper look but can’t see how to remove it.

The other side of the switch with the copper ring and contacts looks at a glance like it could be slightly deformed, ie., one contact is closer than the other. Need to look closer at this.

I cleaned the grease out of the bearings and ran it without the caps on but this doesn’t make any difference, though I’ve ordered a new set anyway as they’re well past their best.

Ali

Member

- Messages

- 1,939

- Location

- Cheshire

I have motors..your welcome to have a sniff about and see if one will do you

Thanks mate, it’s starting to look that way so good to have a backup plan. Just when I was thinking I didn’t need the machine for a bit (dangerous thought) something has come up

roofman

Purveyor of fine English buckets and mops

- Messages

- 13,153

- Location

- North West with water on 3 sides

Ok..if you need one just let me know. Will be around friday sometime as its forecast rain.Thanks mate, it’s starting to look that way so good to have a backup plan. Just when I was thinking I didn’t need the machine for a bit (dangerous thought) something has come up