Hi i have an old sealey mightymig 90 auto with feed issues, it runs fine for a minute or two then progressively gets worse at feeding the wire, becoming very jerky.

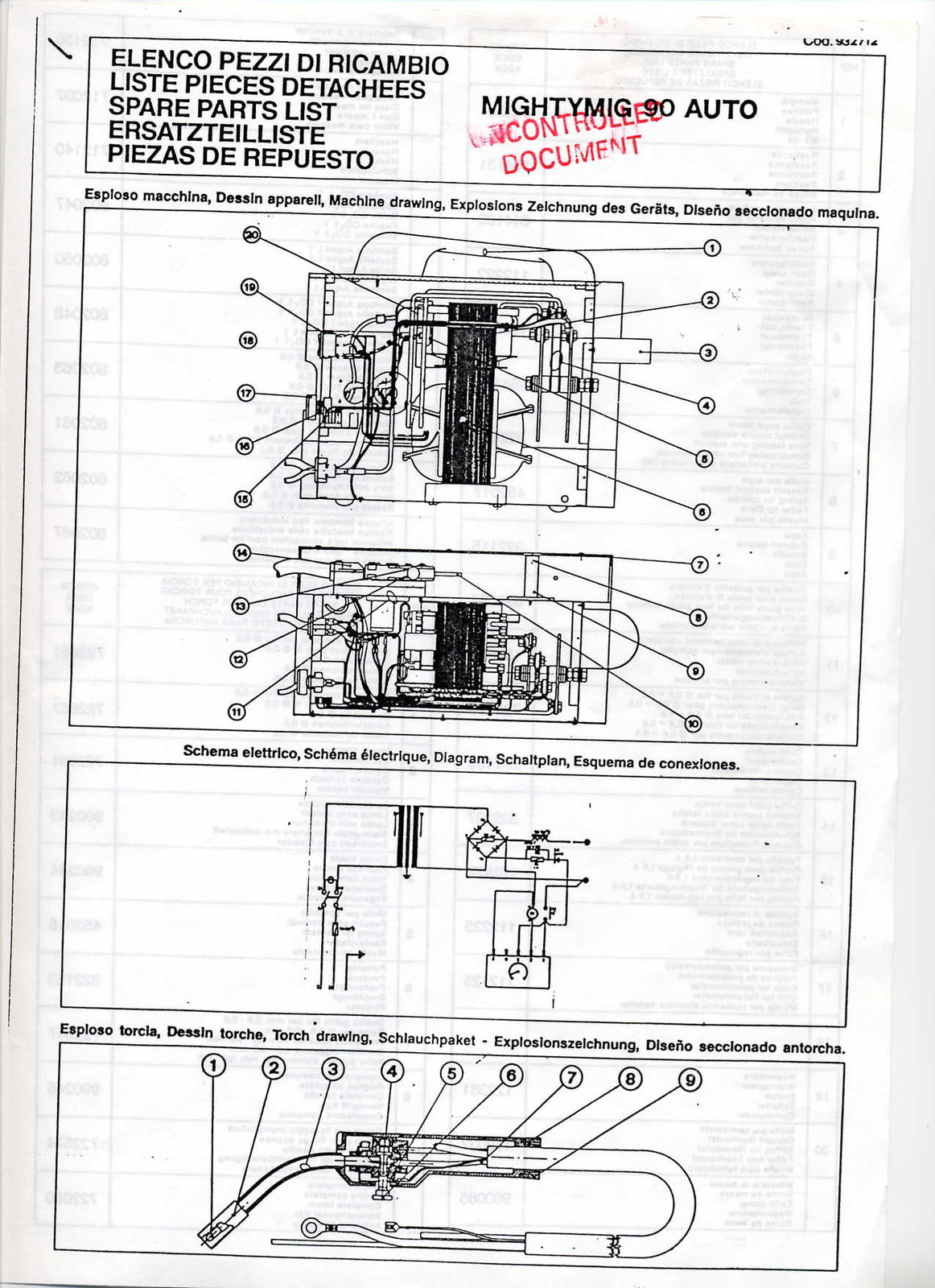

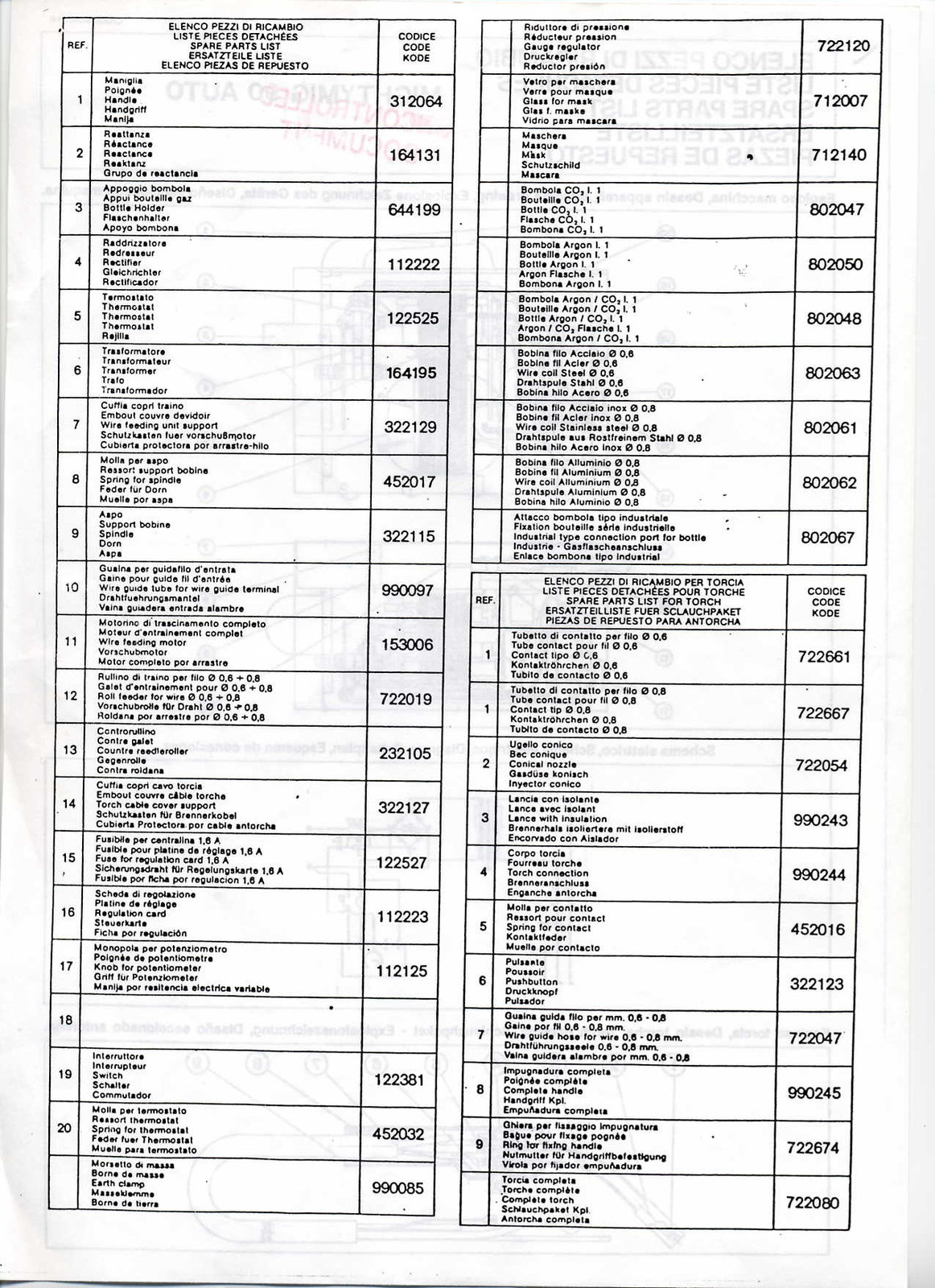

i have replaced the electrolytic caps on the drive board so far with no improvement, also tried new tips, new liner, rebuilt feed gearbox and lubricated gear shafts.

Thinking of trying to replace the motor and or adding seperate drive power supply.

any input welcome

i have replaced the electrolytic caps on the drive board so far with no improvement, also tried new tips, new liner, rebuilt feed gearbox and lubricated gear shafts.

Thinking of trying to replace the motor and or adding seperate drive power supply.

any input welcome