You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Migatronic 325 compact

- Thread starter Topi

- Start date

Hello, and welcome to the Forum !

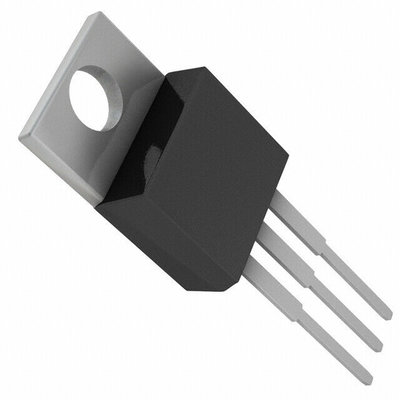

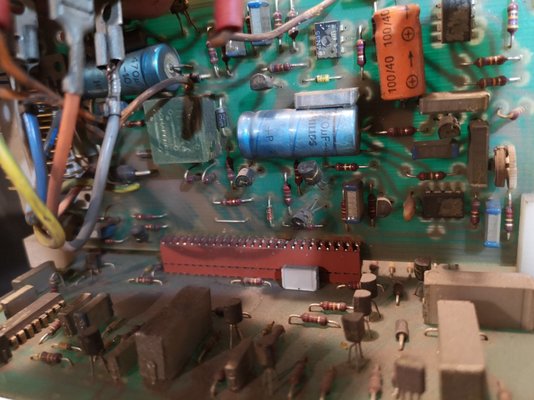

The problem sounds like a failed component on the Control PCB, in the motor speed controller. Could be a power transistor that has gone short-circuit. If you have electronic skills, or know someone that does, start by checking any large transistors on that board - ones with heatsinks - for collector-emitter shorts. If not, let us see a photo of that PCB, and also any precise model numbers for your MIG and on the PCB, to try to find a Manual and a circuit diagram.

The problem sounds like a failed component on the Control PCB, in the motor speed controller. Could be a power transistor that has gone short-circuit. If you have electronic skills, or know someone that does, start by checking any large transistors on that board - ones with heatsinks - for collector-emitter shorts. If not, let us see a photo of that PCB, and also any precise model numbers for your MIG and on the PCB, to try to find a Manual and a circuit diagram.

Thank you! I will load couple of photos.Hello, and welcome to the Forum !

The problem sounds like a failed component on the Control PCB, in the motor speed controller. Could be a power transistor that has gone short-circuit. If you have electronic skills, or know someone that does, start by checking any large transistors on that board - ones with heatsinks - for collector-emitter shorts. If not, let us see a photo of that PCB, and also any precise model numbers for your MIG and on the PCB, to try to find a Manual and a circuit diagram.

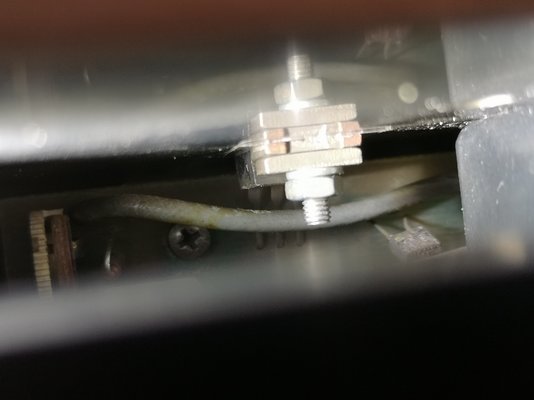

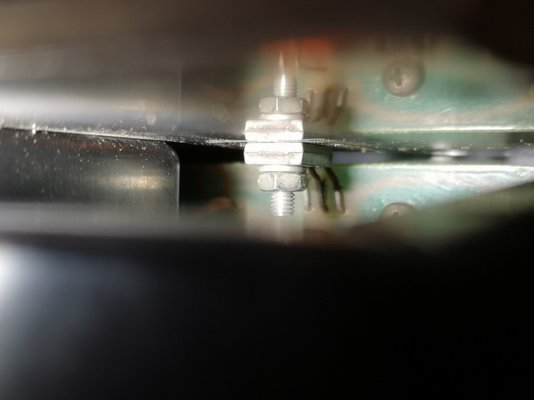

Pics from Electronic

-

IMG_20200227_060200.jpg396.6 KB · Views: 167

IMG_20200227_060200.jpg396.6 KB · Views: 167 -

IMG_20200227_060256.jpg375.1 KB · Views: 148

IMG_20200227_060256.jpg375.1 KB · Views: 148 -

IMG_20200227_060056.jpg255 KB · Views: 152

IMG_20200227_060056.jpg255 KB · Views: 152 -

IMG_20200227_055847.jpg264.5 KB · Views: 183

IMG_20200227_055847.jpg264.5 KB · Views: 183 -

IMG_20200227_060141.jpg282.7 KB · Views: 165

IMG_20200227_060141.jpg282.7 KB · Views: 165 -

IMG_20200227_060557_1.jpg281.1 KB · Views: 155

IMG_20200227_060557_1.jpg281.1 KB · Views: 155 -

IMG_20200227_060511.jpg256.8 KB · Views: 148

IMG_20200227_060511.jpg256.8 KB · Views: 148

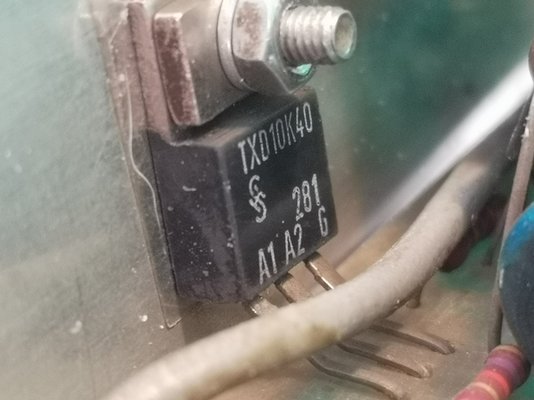

The Siemens TXD10K40 in your post #10 is a 400v 8Amp Triac. It is a switching device for AC. It is just possible that it could be the motor speed controller, but only if the wirefeed motor is an AC motor, which would be unusual. Mostly these motors are DC, but I'm not familiar with large 300 Amp MIG welders.

If that Triac is short-circuit, the pins A1 to A2, and vice-versa, would be a low resistance all the time. On a good Triac, those pins only conduct when there is a trigger pulse on the gate pin G.

On the smaller power transistor - post #11 - I can't see the part number.

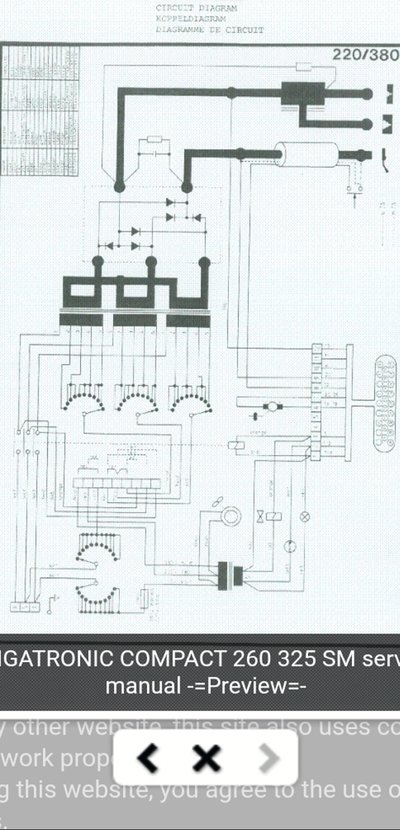

What is the exact model number of your MIG, and are there any numbers on the PCBs, to try to find a Manual and a circuit diagram?

Without a diagram, can you trace the wires from the motor to the PCBs and components?

Please check the voltage across the motor when it is running continuously, to confirm if it is DC or AC.

If that Triac is short-circuit, the pins A1 to A2, and vice-versa, would be a low resistance all the time. On a good Triac, those pins only conduct when there is a trigger pulse on the gate pin G.

On the smaller power transistor - post #11 - I can't see the part number.

What is the exact model number of your MIG, and are there any numbers on the PCBs, to try to find a Manual and a circuit diagram?

Without a diagram, can you trace the wires from the motor to the PCBs and components?

Please check the voltage across the motor when it is running continuously, to confirm if it is DC or AC.

ill get to migatronic today and take photo of serial number of machine and the control unit. I have unit here now in my home ill take the picture now. and have some measure with multimeter. Thanks you a lot Eddie you are super! I have founded some wiring diagrams of migatronic 325 compact from depths of internet but they are pretty poor quality. And by the way there was a random few seconds period when machine starts feeding slower when feeding controller stands low position.. Then full a head again. I remember now.

I am pleased that the MIG does weld very well !

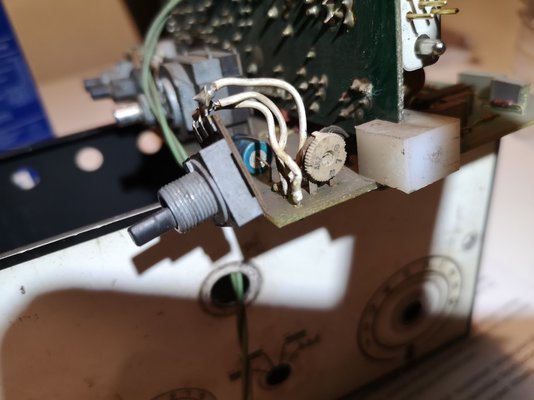

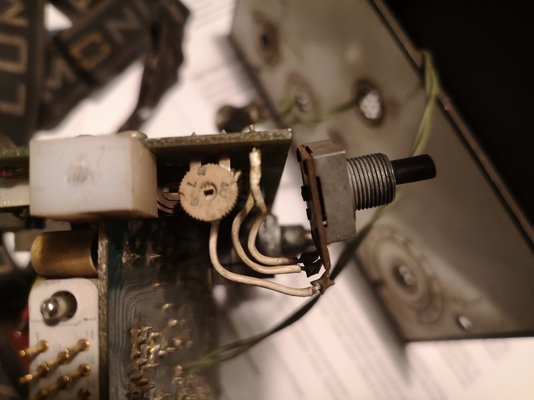

In your post #11 there is a small plastic transistor, bolted with a mica washer under it. It might be a power transistor. Could you remove the bolt and take a photo so we can see the markings?

One way to eliminate the problem would be to replace the motor speed controller with a new pulse-width-modulated ( PWM ) motor controller:

https://www.ebay.co.uk/itm/DC-6V-28...gulator-Controller-Switch-Module/163546933627

You could feed that new controller with 24v DC taken from the original PCB, or even add a stabilised 24v 3A power supply:

https://www.ebay.co.uk/itm/3V-5V-9V...-Supply-Driver-Adapter-LED-Strip/254289649333

In your post #11 there is a small plastic transistor, bolted with a mica washer under it. It might be a power transistor. Could you remove the bolt and take a photo so we can see the markings?

One way to eliminate the problem would be to replace the motor speed controller with a new pulse-width-modulated ( PWM ) motor controller:

https://www.ebay.co.uk/itm/DC-6V-28...gulator-Controller-Switch-Module/163546933627

You could feed that new controller with 24v DC taken from the original PCB, or even add a stabilised 24v 3A power supply:

https://www.ebay.co.uk/itm/3V-5V-9V...-Supply-Driver-Adapter-LED-Strip/254289649333