I have had a kende 200t welder for a good few years and never had any issues with it contrary to popular belief. I however decided to upgrade a few things on it now am using it more.

First off was a quality mb25 torch to enable consumables to be easily sourced,

Then I changed to 0.6 wire to make car bodywork easier but since then have had intermittent wire feed problems which I presumed was down to the feed system, when starting up sometimes it was a bit jerky on start up. I was given an industrial sized wire feed and checked my board to see if it was powerful enough. Luckily the components were rated above the requirements. So today I fitted the motor and what a difference, it is far better. As I got the motor assembly for free if my control board does prove not up to the task I will simply fit a universal one. I could have played safe and bought a new 25w motor but this was as much as a control board so I will take the risk. Here's a few pics of old and new.

The welder

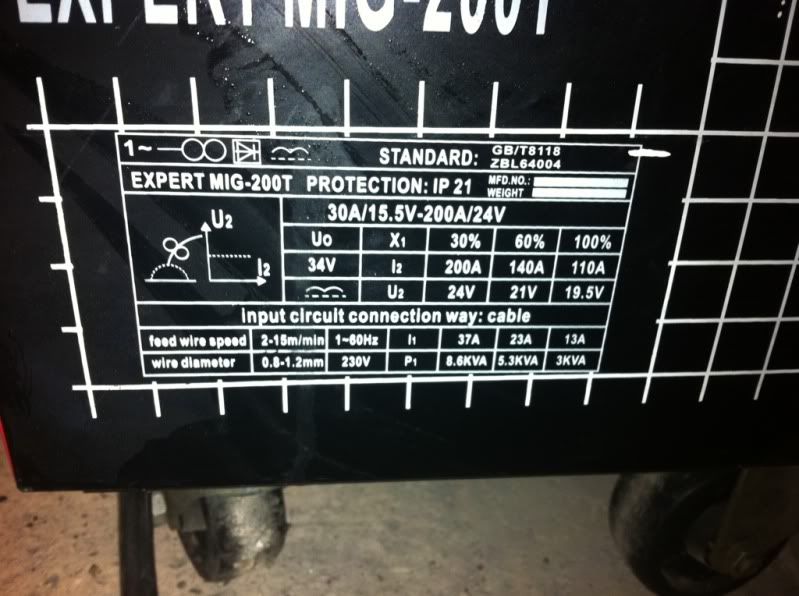

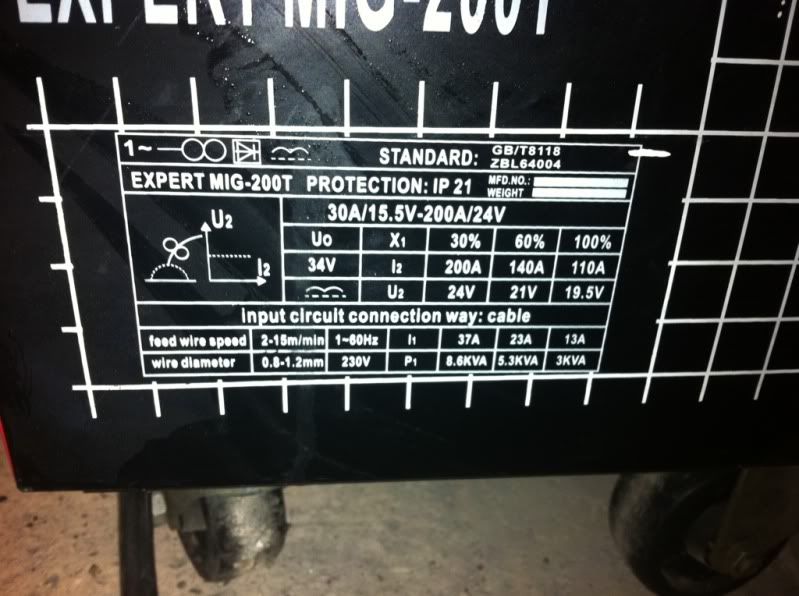

Claimed output settings

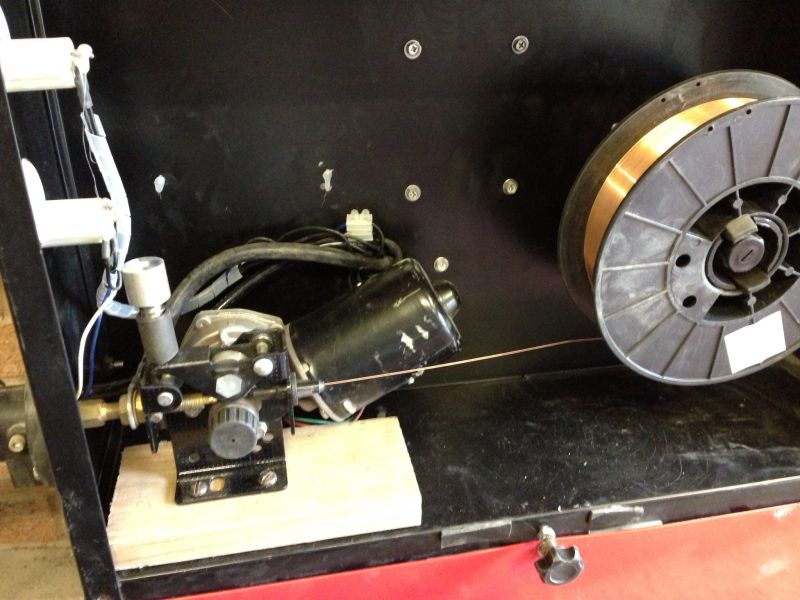

Old wire feed

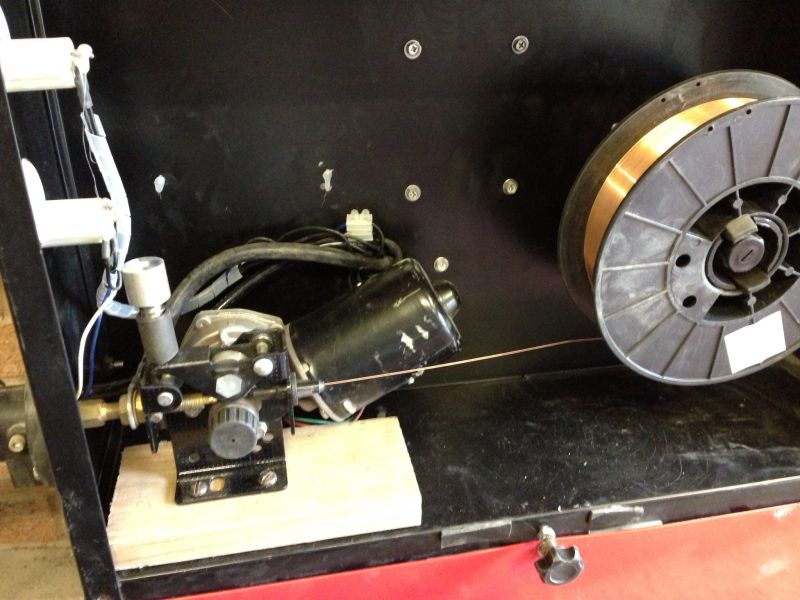

New one

I also noticed an improvement in my welds after fitting this they look more consistent and had perfect penetration. So glad I did it now as was thinking of changing the welder, it was only after our welding supplier and repairer at work had a look and donated the motor that I decided to give it a go. It was well worth the time and effort.

I even got to use my lathe as had to make an adjustment knob as it was missing.

First off was a quality mb25 torch to enable consumables to be easily sourced,

Then I changed to 0.6 wire to make car bodywork easier but since then have had intermittent wire feed problems which I presumed was down to the feed system, when starting up sometimes it was a bit jerky on start up. I was given an industrial sized wire feed and checked my board to see if it was powerful enough. Luckily the components were rated above the requirements. So today I fitted the motor and what a difference, it is far better. As I got the motor assembly for free if my control board does prove not up to the task I will simply fit a universal one. I could have played safe and bought a new 25w motor but this was as much as a control board so I will take the risk. Here's a few pics of old and new.

The welder

Claimed output settings

Old wire feed

New one

I also noticed an improvement in my welds after fitting this they look more consistent and had perfect penetration. So glad I did it now as was thinking of changing the welder, it was only after our welding supplier and repairer at work had a look and donated the motor that I decided to give it a go. It was well worth the time and effort.

I even got to use my lathe as had to make an adjustment knob as it was missing.