Hi there,

I'm looking at a bargain for a reasonable machine. It's a china thing but this one actually seems tot get good reviews : mig star 210.

One thing that's holding me back is that it only begins at 50A. According to the seller, running 17V/50A with 0.8mm wire is just fine for bodywork.

According to interweb specs I've found, it begins at 20 or 22V open voltage (?).

Any insights here? Is less truely more?

I'm looking at a bargain for a reasonable machine. It's a china thing but this one actually seems tot get good reviews : mig star 210.

One thing that's holding me back is that it only begins at 50A. According to the seller, running 17V/50A with 0.8mm wire is just fine for bodywork.

According to interweb specs I've found, it begins at 20 or 22V open voltage (?).

Any insights here? Is less truely more?

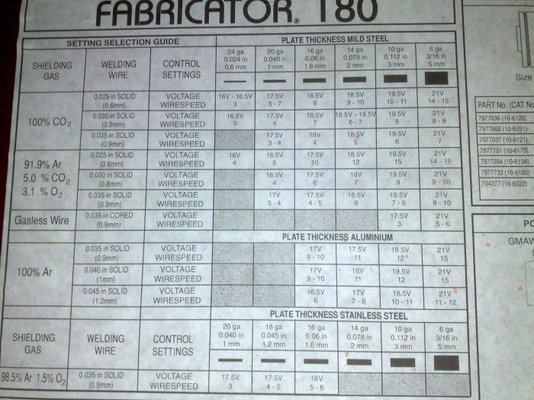

.....not heard of the machine you are asking about but i will post a pic of the settings from my thermal arc 180,where you can see with co2 or argon mix 17volts is not out of the ball park for car repairs...Personally I don't worry too much about amperage often using higher than recommended,but always using "the thin metal technique" which is overlapping spots , because of distortion I never weld more than 1/2" on any side of a car patch/repair in one go , it would end up a mess....I run beads on thicker material but never on car bodywork.....I'm not convinced by Engineer's views on alluminium windings either ,duty cycle and longevity may be worse but functionality is fine at least with clarke/snap-on and sealey diy sets I have used....hope this helps .............

.....not heard of the machine you are asking about but i will post a pic of the settings from my thermal arc 180,where you can see with co2 or argon mix 17volts is not out of the ball park for car repairs...Personally I don't worry too much about amperage often using higher than recommended,but always using "the thin metal technique" which is overlapping spots , because of distortion I never weld more than 1/2" on any side of a car patch/repair in one go , it would end up a mess....I run beads on thicker material but never on car bodywork.....I'm not convinced by Engineer's views on alluminium windings either ,duty cycle and longevity may be worse but functionality is fine at least with clarke/snap-on and sealey diy sets I have used....hope this helps .............

, the lowest amp output on a small or hobby welder is quite important. As the low end of the output on relatively cheap migs goes up the scale, the more difficult it becomes to use the manual 'on-off' stitching technique. When you are manually stitching 0.8 to 1 mm body panels on a cheapy m/c with a low end of 50A you are really on the edge.

, the lowest amp output on a small or hobby welder is quite important. As the low end of the output on relatively cheap migs goes up the scale, the more difficult it becomes to use the manual 'on-off' stitching technique. When you are manually stitching 0.8 to 1 mm body panels on a cheapy m/c with a low end of 50A you are really on the edge.