Davek0974

****!, Drink!, Girls!

- Messages

- 918

- Location

- Hertfordshire

Trying to figure out if i have an issue or not, not been happy with my welds for some time now, can't remember how long. These are all on 3mm bright mild, various wire speed and voltages.

The welds always seem high to me, i have never managed to get a concave surface, always proud, just varying degrees of proud.

Gas is Hobbyweld5 @ 9lpm, indoors welding on an R-Tech I-Mig160 with 0.8mm ER70s6.

Straight butt weld stringers....

Fillet with a circular weave...

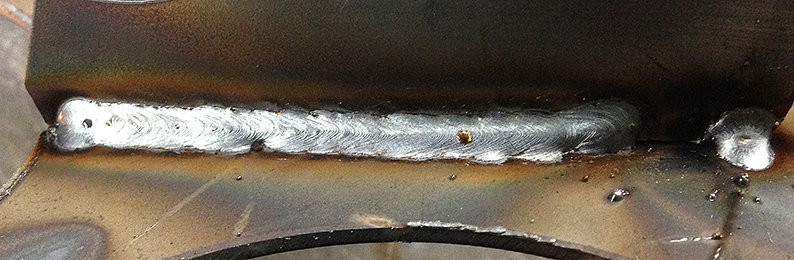

Fillet with a left/right whip...

The whip pattern looks ok to me but considering this a 3mm sheet fillet, its very big and wide.

I can never get a bacon sizzle either, there is always a cracking or crackling sound - much more pronounced than a sizzle. I have today tried just every combination of voltage and feed speed and a sizzle was never to be heard. The arc-force knob seems best left mid-way.

So, using these pics what am i looking at here? I'm not looking to get coded, I make garden brackets etc so 'reasonable' would be the target i think.

The welds always seem high to me, i have never managed to get a concave surface, always proud, just varying degrees of proud.

Gas is Hobbyweld5 @ 9lpm, indoors welding on an R-Tech I-Mig160 with 0.8mm ER70s6.

Straight butt weld stringers....

Fillet with a circular weave...

Fillet with a left/right whip...

The whip pattern looks ok to me but considering this a 3mm sheet fillet, its very big and wide.

I can never get a bacon sizzle either, there is always a cracking or crackling sound - much more pronounced than a sizzle. I have today tried just every combination of voltage and feed speed and a sizzle was never to be heard. The arc-force knob seems best left mid-way.

So, using these pics what am i looking at here? I'm not looking to get coded, I make garden brackets etc so 'reasonable' would be the target i think.

and try not to jerk away your torch at the end of the bead that causes the small pinhole at the end....post gas setting would be nice, does your kit have that?

and try not to jerk away your torch at the end of the bead that causes the small pinhole at the end....post gas setting would be nice, does your kit have that?