arresttwo007

New Member

- Messages

- 10

- Location

- Scotland

Hi folks, just wondering if anyone here is familiar with this machine?

I got it FOC, its never worked great tbh.

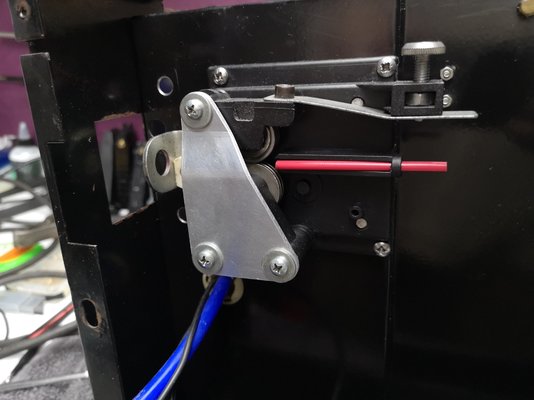

The main attachment for the cord at the machine end was broken, the cord and gun are not the original, it was sort of cobbled together... poorly. The bracket to attach the cord is a piece of angle... held on with one bolt, so the slightest bump misaligns the whole thing with the feeder.

So thats number 1 job, get that mounted solid, even if just temporary while I consider other options.

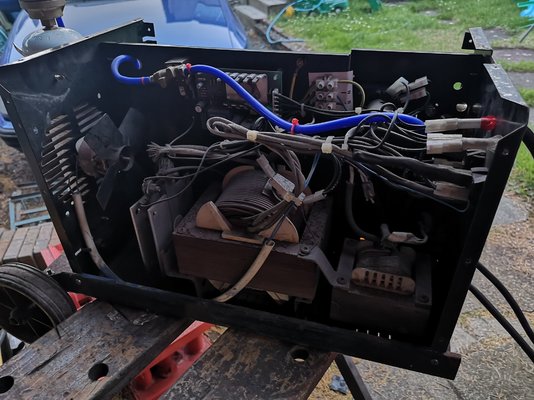

The wire feeder looks like yer pretty typical SIP type I've seen in other threads on here, will benefit from a bracer for sure as I can see the upper pivot and the lower serated wheel mount spreading under pressure.

Feeding, while not great, isn't the best and just making things harder for me - I'm working through old threads on here to scavenge ideas.

Might poss convert to Euro but I'd like to at least have an idea that the base unit is going to work well before going to that.

I'm not entirely trusting that the gas is flowing well from up the cord and out of the tip. Theres a solenoid for the flow in the machine, but no valve inside the gun itself. Am I right in thinking this means arc starting is always going to be hit or miss since theres nothing to stop shielding gas oozing out the end of the torch while not in use / between welds?

I've been mostly using it with gasless wire so I don't even need to consider this issue for now. Welds are very hard to get decent to be honest... while I'm no expert I know its not me because I had no problem with the college machines many moons ago.

Also, the polarity I am assuming is set for shielding gas and plain wire, just how much of a difference does reversing it (like I'm reading you are meant to everywhere) make when using flux cored wire?

Sorry for all the questions! If anyone is familiar with this machine it would be a great help... just so I know how much might be relevant from mods done on other machines!

I got it FOC, its never worked great tbh.

The main attachment for the cord at the machine end was broken, the cord and gun are not the original, it was sort of cobbled together... poorly. The bracket to attach the cord is a piece of angle... held on with one bolt, so the slightest bump misaligns the whole thing with the feeder.

So thats number 1 job, get that mounted solid, even if just temporary while I consider other options.

The wire feeder looks like yer pretty typical SIP type I've seen in other threads on here, will benefit from a bracer for sure as I can see the upper pivot and the lower serated wheel mount spreading under pressure.

Feeding, while not great, isn't the best and just making things harder for me - I'm working through old threads on here to scavenge ideas.

Might poss convert to Euro but I'd like to at least have an idea that the base unit is going to work well before going to that.

I'm not entirely trusting that the gas is flowing well from up the cord and out of the tip. Theres a solenoid for the flow in the machine, but no valve inside the gun itself. Am I right in thinking this means arc starting is always going to be hit or miss since theres nothing to stop shielding gas oozing out the end of the torch while not in use / between welds?

I've been mostly using it with gasless wire so I don't even need to consider this issue for now. Welds are very hard to get decent to be honest... while I'm no expert I know its not me because I had no problem with the college machines many moons ago.

Also, the polarity I am assuming is set for shielding gas and plain wire, just how much of a difference does reversing it (like I'm reading you are meant to everywhere) make when using flux cored wire?

Sorry for all the questions! If anyone is familiar with this machine it would be a great help... just so I know how much might be relevant from mods done on other machines!