shorter_alexander

Member

- Messages

- 35

- Location

- Tunbridge wells

Hi guys,

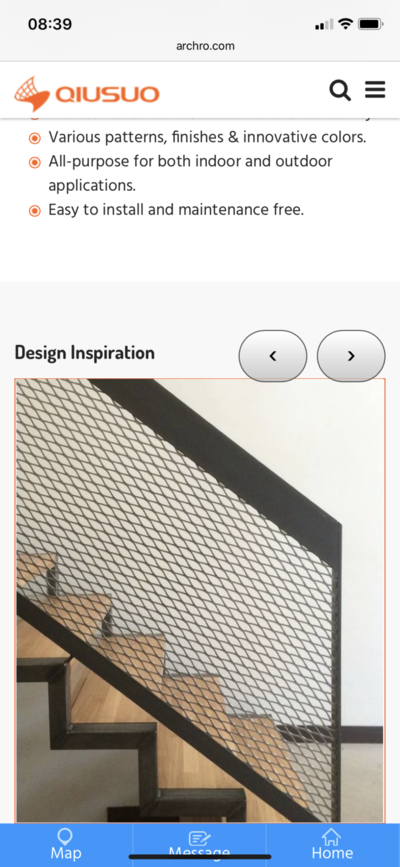

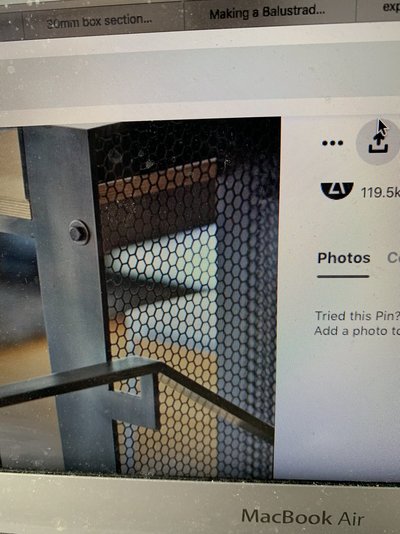

so I need to make a balustrade for a garden retaining wall at a property I own. I want to make it out of 30mm box section and expanded steel. it will be rectangular with 2 feet (atleast) either end and possibly one in the middle. My question is how long can 30mm box section run before it gets unstable? I need the balustrade to be 30mm as its in front of a set of windows and need to keep the balustrade lined up with the window mullions which are also 30mm so it looks good and light isn't blocked out too much. The entire run will be 3m. In an ideal world the 30mm box would run the entire length with no supports in the middle but this may be unrealistic. Any help would be amazing?

Thanks guys.

so I need to make a balustrade for a garden retaining wall at a property I own. I want to make it out of 30mm box section and expanded steel. it will be rectangular with 2 feet (atleast) either end and possibly one in the middle. My question is how long can 30mm box section run before it gets unstable? I need the balustrade to be 30mm as its in front of a set of windows and need to keep the balustrade lined up with the window mullions which are also 30mm so it looks good and light isn't blocked out too much. The entire run will be 3m. In an ideal world the 30mm box would run the entire length with no supports in the middle but this may be unrealistic. Any help would be amazing?

Thanks guys.