You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machine taps.

- Thread starter Slowcoach

- Start date

Agroshield

Member

- Messages

- 6,390

As Brad says, the coding relates to tolerance.

If you look at this page:

www.sandvik.coromant.com

www.sandvik.coromant.com

ISO 2 is a tolerance class in the ISO system of standards. It is equivalent to 6H in the DIN system of standards.

On the sizes, for standard ISO metric coarse threads, the pitch is not given. To put it another way, if the pitch is not given, you should assume it is standard coarse pitch. If the pitch is given, it will be one of the other thread series (e.g. fine, extra fine).

If you look at this page:

Sandvik Coromant

ISO 2 is a tolerance class in the ISO system of standards. It is equivalent to 6H in the DIN system of standards.

On the sizes, for standard ISO metric coarse threads, the pitch is not given. To put it another way, if the pitch is not given, you should assume it is standard coarse pitch. If the pitch is given, it will be one of the other thread series (e.g. fine, extra fine).

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

are they spiral flute?

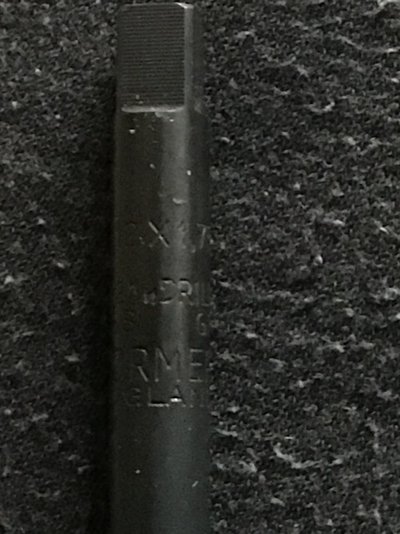

Yes, had to zoom in to take a pic of the shank or you couldn’t see the marking.are they spiral flute?

Thanks @Agroshield thats very helpful.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,518

- Location

- France, Brittany.

Everyday is a learning day, thanks all.

Was discussing this earlier, but was none the wiser.

Borrowed a Stahl Meistser 1/8 BSP die from the neighbours motor engineering company, and expressed my admiration for their huge box of taps and dies.

Ex retired garage owner, said yes, but no, the tollerances, are not ideal, play in nuts and bolts.

I didn't look carefully at the coding.

It was very tight, when I screwed it in, but I unscrewed, it to check I had the right thread, which I had.

Was discussing this earlier, but was none the wiser.

Borrowed a Stahl Meistser 1/8 BSP die from the neighbours motor engineering company, and expressed my admiration for their huge box of taps and dies.

Ex retired garage owner, said yes, but no, the tollerances, are not ideal, play in nuts and bolts.

I didn't look carefully at the coding.

It was very tight, when I screwed it in, but I unscrewed, it to check I had the right thread, which I had.

Agroshield

Member

- Messages

- 6,390

I didn't look carefully at the coding.

It was very tight, when I screwed it in, but I unscrewed, it to check I had the right thread, which I had.

Do not overthink this. If you look at the pdf Brad posted, ISO2/6H is the tolerance used for probably 99% of threading gear. That means to buy anything other than this would be a special order and increased cost (supply and demand). You would only go tighter than this if you have an engineering requirement to do so. You only go looser than this if a subsequent process involves plating the threads you have made. So best not to buy a job lot of taps from the local galvanisers that has just closed down.

frank horton

V twins are great but 4"s rule.........

- Messages

- 4,667

- Location

- Crete, Greece

it all mean poo....depends on the size of drill and how many times it's be used, let alone ground proper.....hahaha.....

1/2 the bolts u buy today are really carp anyway.....

I have a huge selection of BA, Whit Bsf, Pipe and the usual UN series and Metric both fine and course......

nobody goes in that drawer but me.....

and yes I still come across threads I dont have.....have even found some hand made threads of yester year....

all very interesting.....

1/2 the bolts u buy today are really carp anyway.....

I have a huge selection of BA, Whit Bsf, Pipe and the usual UN series and Metric both fine and course......

nobody goes in that drawer but me.....

and yes I still come across threads I dont have.....have even found some hand made threads of yester year....

all very interesting.....

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

One other thing to say is spiral flute are good for blind holes but if tapping a through hole spiral point are far superior, they tap easier, have more strength in the tap itself and push the swarf in front so no recutting of swarf like you can get with a spiral flute.

I often use spiral point in a blind hole as they are much nicer, just need to make sure there is enough depth below the end of the thread for the swarf to collect or remove a few times to clear the swarf.

I often use spiral point in a blind hole as they are much nicer, just need to make sure there is enough depth below the end of the thread for the swarf to collect or remove a few times to clear the swarf.

6H is a medium fit for internal - 6G would be the equivalent of external - usual general purpose.

British Standard set all this out - together with drill sizes for tapping and clearance (which some of the standard details in a few 3D CAD systems don't follow and get wrong!). They also set out run-outs for internal and external threads, as well as undercuts etc. If I'm designing something, I'd try to allow sufficient run out to avoid the need to use plug taps. And if it makes no difference to the operation of my part, for the sake of a few millimetres, I'll run holes clean through, even if I don't do the same with the thread. Just makes making it quicker and helps prevent us finding swarf stuck in blind holes when something fails when the machine is in operation.

We would usually specify tapping drill for any internal thread to control what we get (ie not rely on someone thinking "that'll be right . . "), but we are more often using roll/forming taps inhouse, so its gets a bit more complicated - our parts could be made in-house or externally.

As well going looser to allow for plating thickness, we use looser threads when we also have a location diameter on the part - allows for some misalignment of the thread to the location, and allows the location diameter to position the part without the thread fighting it.

British Standard set all this out - together with drill sizes for tapping and clearance (which some of the standard details in a few 3D CAD systems don't follow and get wrong!). They also set out run-outs for internal and external threads, as well as undercuts etc. If I'm designing something, I'd try to allow sufficient run out to avoid the need to use plug taps. And if it makes no difference to the operation of my part, for the sake of a few millimetres, I'll run holes clean through, even if I don't do the same with the thread. Just makes making it quicker and helps prevent us finding swarf stuck in blind holes when something fails when the machine is in operation.

We would usually specify tapping drill for any internal thread to control what we get (ie not rely on someone thinking "that'll be right . . "), but we are more often using roll/forming taps inhouse, so its gets a bit more complicated - our parts could be made in-house or externally.

As well going looser to allow for plating thickness, we use looser threads when we also have a location diameter on the part - allows for some misalignment of the thread to the location, and allows the location diameter to position the part without the thread fighting it.

Agroshield

Member

- Messages

- 6,390

As well going looser to allow for plating thickness, we use looser threads when we also have a location diameter on the part - allows for some misalignment of the thread to the location, and allows the location diameter to position the part without the thread fighting it.

It would be interesting to see if there is anything published in this regard relating to ER collet chucks and nuts. From what you say above, the ER ones should be loose so the threads do not influence the collet concentricity - the collet back taper should do the locating and the nut should follow the front taper.