h-dom

Member

- Messages

- 595

- Location

- Lincs

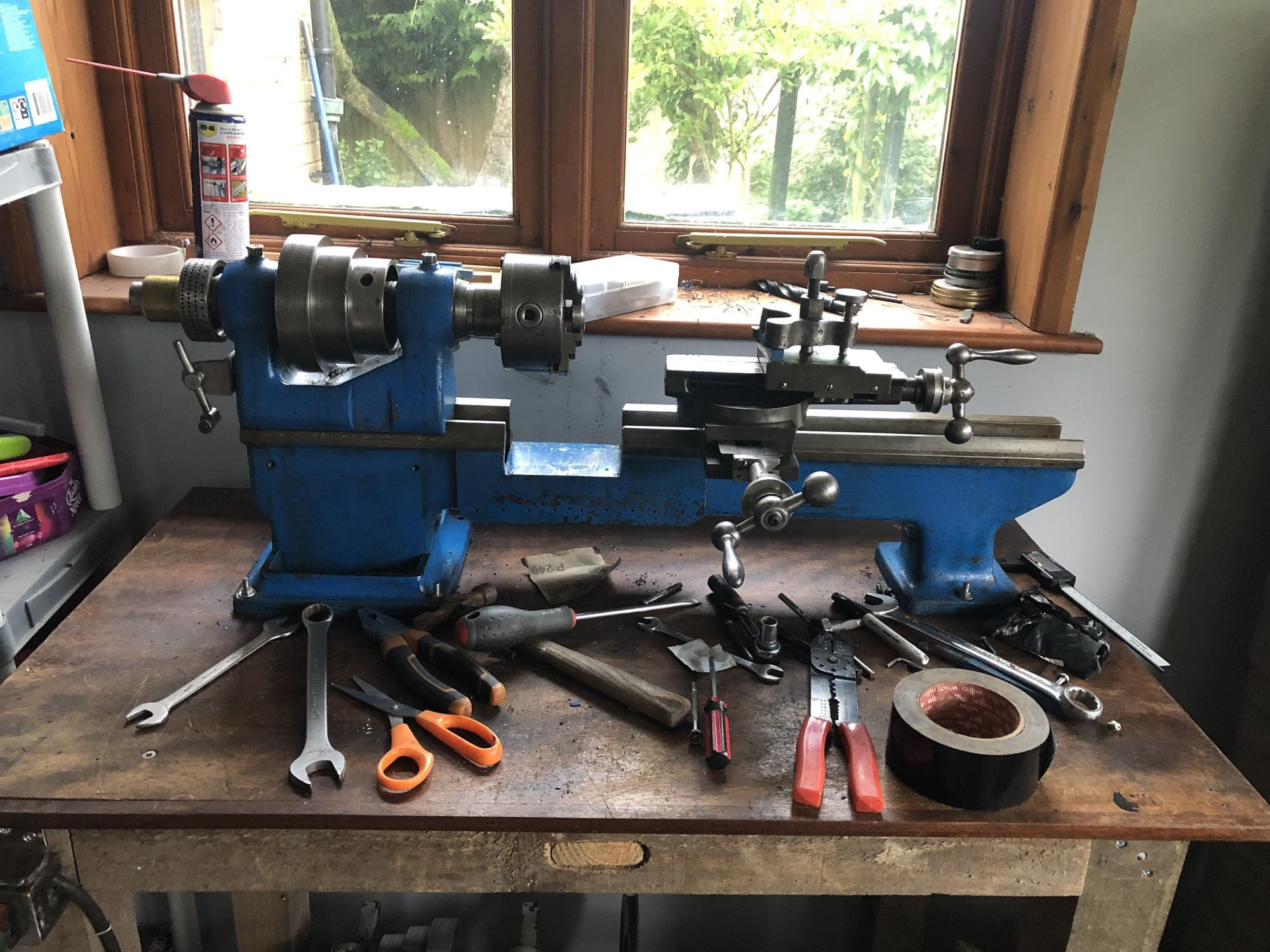

Some of you may have seen I recently posted about needing a shaft turning and I was struggling to get it done, I thought stuff it and found this little lathe fairly locally to me and I could just squeeze the shaft in between the centres so did it myself. I have never used a lathe before although this Lorch is clearly old and fairly basic I do need some practice getting a good finish!

When I got it the shaft the cross feed screw fits in was snapped and had been brazed badly before, no matter what I did I couldn’t get it to hold, I think it had been dropped at some point because the cross feed screw was bent which was putting pressure on it every time it was brazed. So I machined a new shaft, welded on the collar at the end and bored a 16mm hole for the screw collar to sit in, drilled a 10mm hole for it to slide through and made a new section for the other end, all from mild steel and welded together. Straightened the screw out with my big hammer and it now slides across freely and easily. I had to do all of that using the broken part and now I am finding it is much easier it is holding itself together!!

There is a lot of backlash, the thread is clearly worn on the screws almost to a perfect point on both slides. I have a bit of a project on my hands I think and seeing as I am unable to cut threads on this machine I may need a hand from someone to turn me a couple of new feed screws. Left hand threads too.

Anyway sorry for the rambling, I do like the lathe and it is from the time when things were made to work and look good at the same time. The front plate is off at the moment as I was just giving it a clean up to remove the years of grease and grime.

Can anyone else give me any information on this lathe and from the photos what I need to do to get it back to how it would have been from the Lorch factory? From my research it looks more like the Lorch lathes that were rebranded and sold a Stedall lathes but there are no Stedall markings anywhere.

So here it is

When I got it the shaft the cross feed screw fits in was snapped and had been brazed badly before, no matter what I did I couldn’t get it to hold, I think it had been dropped at some point because the cross feed screw was bent which was putting pressure on it every time it was brazed. So I machined a new shaft, welded on the collar at the end and bored a 16mm hole for the screw collar to sit in, drilled a 10mm hole for it to slide through and made a new section for the other end, all from mild steel and welded together. Straightened the screw out with my big hammer and it now slides across freely and easily. I had to do all of that using the broken part and now I am finding it is much easier it is holding itself together!!

There is a lot of backlash, the thread is clearly worn on the screws almost to a perfect point on both slides. I have a bit of a project on my hands I think and seeing as I am unable to cut threads on this machine I may need a hand from someone to turn me a couple of new feed screws. Left hand threads too.

Anyway sorry for the rambling, I do like the lathe and it is from the time when things were made to work and look good at the same time. The front plate is off at the moment as I was just giving it a clean up to remove the years of grease and grime.

Can anyone else give me any information on this lathe and from the photos what I need to do to get it back to how it would have been from the Lorch factory? From my research it looks more like the Lorch lathes that were rebranded and sold a Stedall lathes but there are no Stedall markings anywhere.

So here it is