Mick Watson

New Member

- Messages

- 2

- Location

- UK

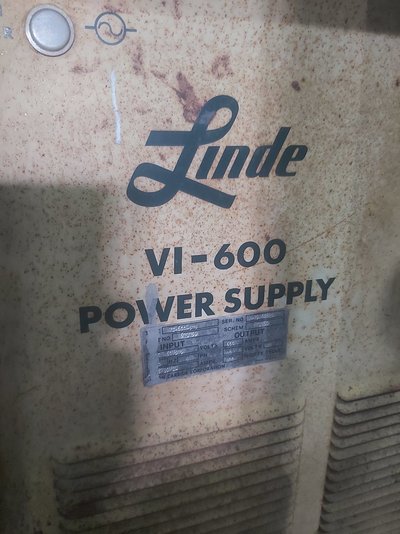

Ok guys over the next few days / weeks I'm going to be picking brains on how I set the beast up for spray transfer . I will be fillet welding 15mm to 15mm and 20mm to 20mm mild steel . I know I need 95% argon . It will be the amps volts and wire speed I will need help with.