You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lidl Plasmas Coming Soon!

- Thread starter Turbo

- Start date

JOEPRO

Member

- Messages

- 5,260

- Location

- UK

The black PPSK40 plasma cutter compressor runs all the time during cutting, and runs on for a few seconds after the trigger is released. In that sense, it "keeps up", supplying a steady stream of air.

All plasma cutters have a run on airflow future to cool the tip and prolong life of consumables

charlysays

Member

- Messages

- 561

- Location

- UK, Wales

I'm sure the ppsk40 does keep up a steady supply but whether that's enough I'm not sure. My 3hp compressor was kicking in a fair bit with the regulator on the plasma set to 4 bar which is what the manual advised (i think, read it in a rush). I can't see an onboard compressor getting anywhere near that level of air flow.The black PPSK40 plasma cutter compressor runs all the time during cutting, and runs on for a few seconds after the trigger is released. In that sense, it "keeps up", supplying a steady stream of air.

zx9

Forum Supporter

- Messages

- 5,185

- Location

- South East London

Here you go.@zx9 would you have a link to the correct 8mm/BSP adapters you got, the 1/2" ones I got are clearly wrong!

That and the Dinse fittings for the earth.

Cheers.

2 sets M & F 10-25 Dinse

1/4 BSP to 8mm push connectors

I used my pilot arc lidl plasma last week to cut some thick-walled high pressure steel pipe. I hooked it up to my 100L belt-drive compressor.... & it had to run continuously to maintain the airflow (set to 4.5bar I think).I'm sure the ppsk40 does keep up a steady supply but whether that's enough I'm not sure. My 3hp compressor was kicking in a fair bit with the regulator on the plasma set to 4 bar which is what the manual advised (i think, read it in a rush). I can't see an onboard compressor getting anywhere near that level of air flow.

Whatever little compressor that is built-in to the on-board ones..... must have to work damned hard I'd have thought?

zx9

Forum Supporter

- Messages

- 5,185

- Location

- South East London

I am confident that supplying air from a compressor will improve the ppsk40's performance with thicker metal which is why I want to posh on with adding an air control solenoid. Can you confirm that the pps30 has an air supply solenoid? And if so but only if you feel confident can you get me some pictures of the main board and solenoid / connections used.I'm sure the ppsk40 does keep up a steady supply but whether that's enough I'm not sure. My 3hp compressor was kicking in a fair bit with the regulator on the plasma set to 4 bar which is what the manual advised (i think, read it in a rush). I can't see an onboard compressor getting anywhere near that level of air flow.

That is a big ask, please only do this if you are happy to open up the case and understand that the inverter runs some very high voltages into some large capacitors. If you have any doubts about opening up the machine do not do it. The same goes for anyone else reading this.

zx9

Forum Supporter

- Messages

- 5,185

- Location

- South East London

The internal compressor lives in a shielded enclosure away from the main board, I did not open up that side on Friday but will next time I have the machine apart if only to find out what they are using. It would be nice to get an idea of the air flow too but the only flow meters I have are post regulator for my tig and not up to the pressure or expected flow.I used my pilot arc lidl plasma last week to cut some thick-walled high pressure steel pipe. I hooked it up to my 100L belt-drive compressor.... & it had to run continuously to maintain the airflow (set to 4.5bar I think).

Whatever little compressor that is built-in to the on-board ones..... must have to work damned hard I'd have thought?

charlysays

Member

- Messages

- 561

- Location

- UK, Wales

That was my experience too. 3hp 150l compressor was working fairly hard to keep up. Could also hear the note of the compressor drop when I pulled the trigger on the plasma so it was pulling some juice from the mains!I used my pilot arc lidl plasma last week to cut some thick-walled high pressure steel pipe. I hooked it up to my 100L belt-drive compressor.... & it had to run continuously to maintain the airflow (set to 4.5bar I think).

Whatever little compressor that is built-in to the on-board ones..... must have to work damned hard I'd have thought?

I did a good 15ft-20ft of cutting without destroying the tip though. With less air I imagine the tip would have fared worse .

I am confident that supplying air from a compressor will improve the ppsk40's performance with thicker metal which is why I want to posh on with adding an air control solenoid. Can you confirm that the pps30 has an air supply solenoid? And if so but only if you feel confident can you get me some pictures of the main board and solenoid / connections used.

That is a big ask, please only do this if you are happy to open up the case and understand that the inverter runs some very high voltages into some large capacitors. If you have any doubts about opening up the machine do not do it. The same goes for anyone else reading this.

I reckon the one I have must have an air control solenoid.... as when you release the trigger there is a delay before it cuts the airflow (to cool the tip I assume?).

There is a water trap filter on the back of the case where you set the pressure/flow but that's just a std common item.

I'm not concerned regarding opening the case & taking a look-see. If I get chance later (& remember lol) I don't mind having a shufti & snapping a couple of pics.

zx9

Forum Supporter

- Messages

- 5,185

- Location

- South East London

Thank you pictures would be much appreciated.I reckon the one I have must have an air control solenoid.... as when you release the trigger there is a delay before it cuts the airflow (to cool the tip I assume?).

There is a water trap filter on the back of the case where you set the pressure/flow but that's just a std common item.

I'm not concerned regarding opening the case & taking a look-see. If I get chance later (& remember lol) I don't mind having a shufti & snapping a couple of pics.

Kram

Member

- Messages

- 8,430

- Location

- Sussex

The internal compressor is not of a great qualitiy construction. I get the impression that high air flow at low pressure, is how it manages acceptable performance without using too much power.

If anyone is able to put a current meter on the compressor, I'd be interested to see what power it uses. However I believe the motor is universal and fed with DC, so an AC clamp current meter is not going to work..

If anyone is able to put a current meter on the compressor, I'd be interested to see what power it uses. However I believe the motor is universal and fed with DC, so an AC clamp current meter is not going to work..

Kram

Member

- Messages

- 8,430

- Location

- Sussex

The problem with tank compressors is it collects in the tank. Without a tank its going straight out again and probably not enough of it to be a problem as the air wont get a chance to cool off /condense.

It'd be nice if compressors had the water trap after the pump and before the tank, but for that you need to cool the air down to ambient.

It'd be nice if compressors had the water trap after the pump and before the tank, but for that you need to cool the air down to ambient.

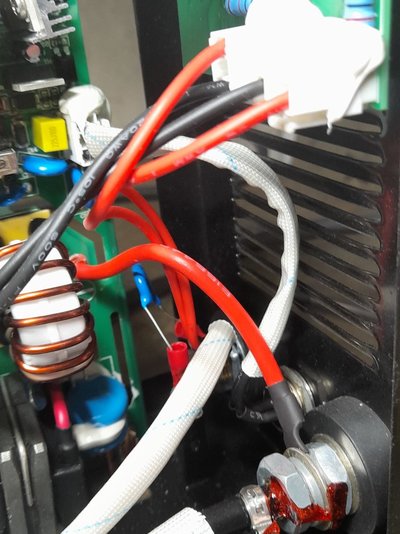

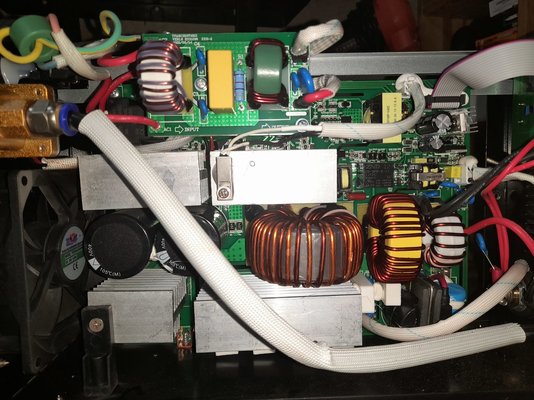

Here you go.....Thank you pictures would be much appreciated.

You can see that immediately behind the casing from the water filter (I have another very similar one I put upstream of this one in the airline as well in use) is the 24v air flow solenoid.

There is one main pcb and a secondary which has the potentiometer for the plasma current output, plus another secondary which is the ac input to output unit.

I've tried to get pics of the wiring on the back of the panel connectors for the torch, pilot arc control & work Return.

You can see there's a blue item (Thyristor?) Off the work return plug to a post on the Case/Chassis, while there is a thick cable on the torch connector that goes to the main pcb (with a -ive symbol by the pcb connection point).

2 wires from the pilot arc socket go to a plug onto the main pcb.

2 black wires off the 2 plugs on the front small pcb go to spade a1 on the main pcb, while the 2 reds join onto the brass work return socket.

(Note I read on here that earlier models had an internal pot to up the output to 40A... but I didnt spot one on my cutter while poking around taking these pics - so perhaps this one cannot be boosted).

zx9

Forum Supporter

- Messages

- 5,185

- Location

- South East London

Interesting video posted earlier in this thread (Feb 2022) includes a look at the compressor which is stated as running rectified mains so around 320V DC. Hum ....There's a teardown of the compressor in this video.

And this video shows it cutting ok up to 5mm steel, anything more than that you need external air supply.

I don't think the internal compressor would be much use for anything more than pumping up bike tyres.

Edit: GRW's one in the pictures is clearly 24V DC. so not a direct piggy back the compressor.

Here are some measurements of the air pressure generated by the internal compressor, during operation of the PPSK 40 B2 plasma cutter. The measurements were made using a pressure gauge connected to the external air input, via a short length of the supplied 8mm push in tubing, so essentially measuring the pressure at the internal T-piece, just before the torch connector. The standard supplied torch was connected up and fitted with the standard supplied centre electrode and copper collar. Measured pressures were as follows: Overrun into free air, (no arc) 20.5psi; 15A arc plasma operating into free air, by "grounding" the collar (pilot arc style) 26.5psi; 40A arc into free air 30.5psi. Pressing the nozzle against a flat sheet of ali during overrun, raised the measured pressure slightly, from 20.5 to 21.5psi. For comparison, it would be interesting to see the pressures a regulated external supply will produce at the torch connection.

zx9

Forum Supporter

- Messages

- 5,185

- Location

- South East London

Way less than the max 4.5 bar or 65 psi they quote for the external air input.Here are some measurements of the air pressure generated by the internal compressor, during operation of the PPSK 40 B2 plasma cutter. The measurements were made using a pressure gauge connected to the external air input, via a short length of the supplied 8mm push in tubing, so essentially measuring the pressure at the internal T-piece, just before the torch connector. The standard supplied torch was connected up and fitted with the standard supplied centre electrode and copper collar. Measured pressures were as follows: Overrun into free air, (no arc) 20.5psi; 15A arc plasma operating into free air, by "grounding" the collar (pilot arc style) 26.5psi; 40A arc into free air 30.5psi. Pressing the nozzle against a flat sheet of ali during overrun, raised the measured pressure slightly, from 20.5 to 21.5psi. For comparison, it would be interesting to see the pressures a regulated external supply will produce at the torch connection.