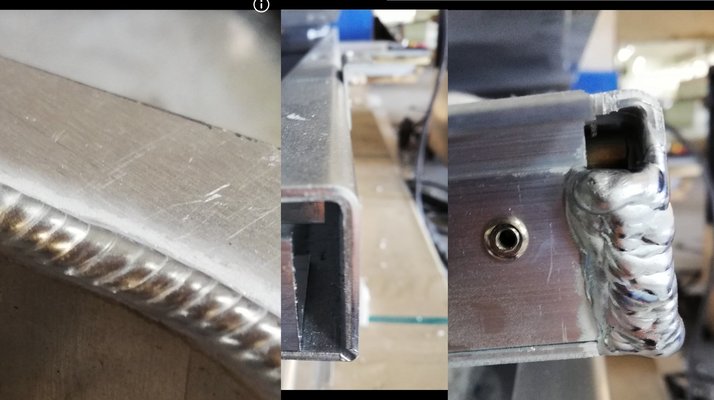

the red lines along the welds are my attempts.

the problem is, when i want to show him something he gests discouraged quickly.

thats just 5 hours, 10-15 mins a day and on staturday we brought some beer to take it on easy and it was somewhere near 1,5h of welding, there was time to explain the difference between tight to long arc and welding on cold or hot material.

on the last pic i see 6 rippless that are somewhere near top class quality, height and width.

*thats my attempt* is that a perfect weld? i would say no. I could done it better, and someone else would make it even better.

he is struggling with closed corners, does well laying beads on flat material.

what type of joint would You guys suggest? i was wondering about lap joints.

the problem is, when i want to show him something he gests discouraged quickly.

thats just 5 hours, 10-15 mins a day and on staturday we brought some beer to take it on easy and it was somewhere near 1,5h of welding, there was time to explain the difference between tight to long arc and welding on cold or hot material.

on the last pic i see 6 rippless that are somewhere near top class quality, height and width.

*thats my attempt* is that a perfect weld? i would say no. I could done it better, and someone else would make it even better.

he is struggling with closed corners, does well laying beads on flat material.

what type of joint would You guys suggest? i was wondering about lap joints.

Oh, and Winter's coming so no grass to cut, outside welding to do [can't do major welds inside a wooden shed

Oh, and Winter's coming so no grass to cut, outside welding to do [can't do major welds inside a wooden shed  ] etc........

] etc........

but turned out decent for what it was i think

but turned out decent for what it was i think

probably. but im doing alot of stuff on CNC and it would be a healthier route, im still thinking. but things like that done 100% correctly to the drawings angles and dimensions are as much rewarding as a great weld!

probably. but im doing alot of stuff on CNC and it would be a healthier route, im still thinking. but things like that done 100% correctly to the drawings angles and dimensions are as much rewarding as a great weld!