Bill,

You're absolutely right about the 4 way toolposts - they're hopeless! I tried using them for a while and gave up, even with short-shanked carbide tools. The tools not in use always get in the way, and are a really easy way to gash your hand wide open. Plus, if you put a boring tool of any length in there, you only have one other useful station. I chucked my 4 way toolpost out, best mod I made to the lathe!

For hobby stuff, as you say, one tool at a time works fine. You soon get to know your shim packs, and having a small height gauge living permanently on the topslide (if it's a flat topped one) helps a lot. I'd guess that tool changing & sharpening takes up about 10 - 15% of total lathe time.

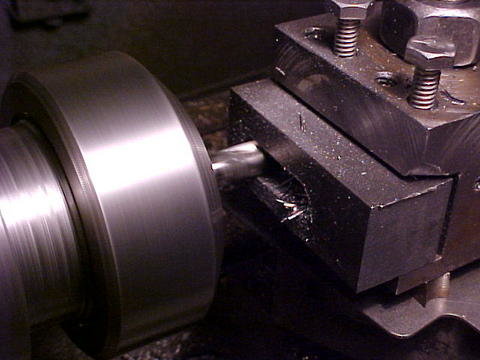

For anything more productive, get a proper quick change toolpost - my present lathe has a T3 Dickson system. These allow really quick, dead accurate tool swaps. Trouble is, you never have enough toolholders...

I guess it comes down to how fast you want to work, and how much cash you have over to achieve that.

Ian

You're absolutely right about the 4 way toolposts - they're hopeless! I tried using them for a while and gave up, even with short-shanked carbide tools. The tools not in use always get in the way, and are a really easy way to gash your hand wide open. Plus, if you put a boring tool of any length in there, you only have one other useful station. I chucked my 4 way toolpost out, best mod I made to the lathe!

For hobby stuff, as you say, one tool at a time works fine. You soon get to know your shim packs, and having a small height gauge living permanently on the topslide (if it's a flat topped one) helps a lot. I'd guess that tool changing & sharpening takes up about 10 - 15% of total lathe time.

For anything more productive, get a proper quick change toolpost - my present lathe has a T3 Dickson system. These allow really quick, dead accurate tool swaps. Trouble is, you never have enough toolholders...

I guess it comes down to how fast you want to work, and how much cash you have over to achieve that.

Ian

![boring[1].jpg](/forum/data/attachments/2/2509-6fb21219c0adb560e718a57c9e0ff546.jpg?hash=b7ISGcCttW)

![cutting groove[1].jpg](/forum/data/attachments/2/2510-aca57476ed87fb187f256249e4877f1f.jpg?hash=rKV0du2H-x)

![cutting_pulley[1].jpg](/forum/data/attachments/2/2511-38dc5507e84568d579263f9b0a09d126.jpg?hash=ONxVB-hFaN)

![turning[1].jpg](/forum/data/attachments/2/2513-90755591fd1bf1c11932031efba60837.jpg?hash=kHVVkf0b8c)

![937e[1].jpg](/forum/data/attachments/2/2517-ca0d78a118f4db737263c1a66ad4b14a.jpg?hash=yg14oRj023)

![247b[1].jpg](/forum/data/attachments/2/2518-2de76b798aebf443f4a1a943cf810c4e.jpg?hash=LedreYrr9E)

![c631[1].jpg](/forum/data/attachments/2/2519-ab328e527a3066bb9de2a7466f0b175e.jpg?hash=qzKOUnowZr)