dieselsamurai

Too many projects not enough time!

- Messages

- 1,591

- Location

- Hampshire

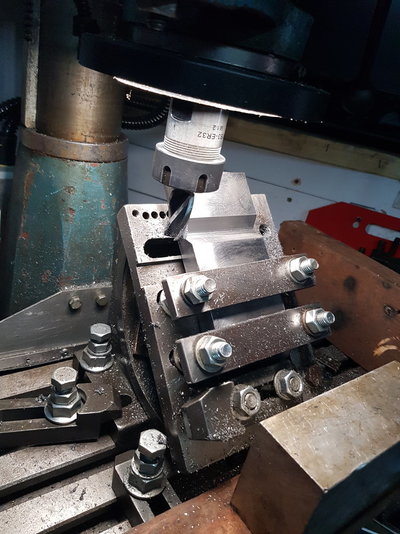

Hi so I bought this Lathe steady I saw on FB as i need to machine some 4" tube and my Lathe only came with a traveling one and Im not going to get one in this country

Is quite a beast but for £75 I couldnt really ignore it . Buyer said it came from an Excel D420 lathe

I was going to make one as I need one and I have all the materials I need just the time and effort

So my question is should I modify it or save it and build one using the roller fingers as it saves a ton of machining

below is how much i would need to take off to make it fit (top of rule) the bed of my lathe is 7 1/2" wide and the steady is 6" wide at the base so I can cut the smaller V and to accomodate the larger one i can cut the angle off the front edge of the steady

opinions welcome

Is quite a beast but for £75 I couldnt really ignore it . Buyer said it came from an Excel D420 lathe

I was going to make one as I need one and I have all the materials I need just the time and effort

So my question is should I modify it or save it and build one using the roller fingers as it saves a ton of machining

below is how much i would need to take off to make it fit (top of rule) the bed of my lathe is 7 1/2" wide and the steady is 6" wide at the base so I can cut the smaller V and to accomodate the larger one i can cut the angle off the front edge of the steady

opinions welcome

![20230729_230846[1].jpg 20230729_230846[1].jpg](https://www.mig-welding.co.uk/forum/data/attachments/407/407109-57fdd74a2837e3a10a8df345d0412df5.jpg?hash=V_3XSig346)