Hi,

beginner here, old lathe which works ok when turning od or driling out stock, however when turning inside diameter the results are terrible.

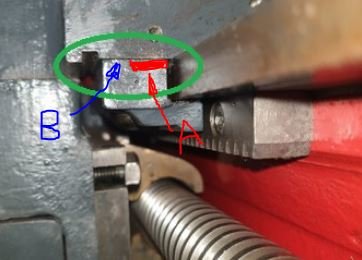

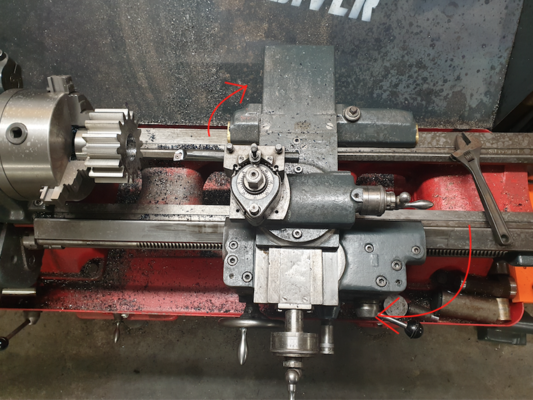

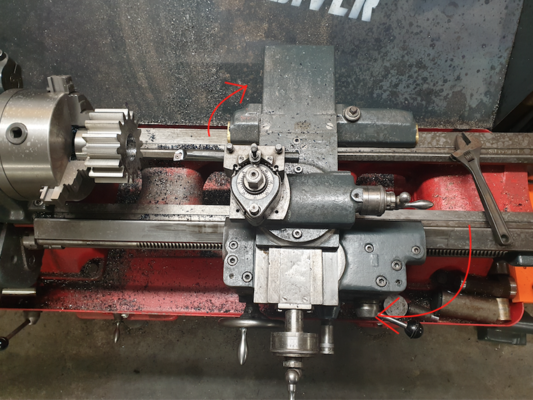

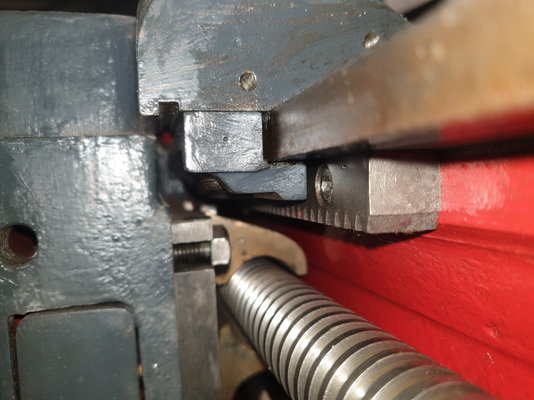

I've noticed there is a bit of play in the carriage (see picture) however i cant find any way to adjust this rotational play, there are no gibs or anything. Is there any way to fix this problem or are the ways/prisma just worn down and is this lathe ready to be scrapped?

As a test i tightende the gibs in the cross and the top slide completely to eliminate them as the source of the chatter, results were still the same.

I can rotate the carriage like the arrows ever so slightly, you can also see it move when i engage the drive. I suspect this is the source of the chatter when doing inside turning.

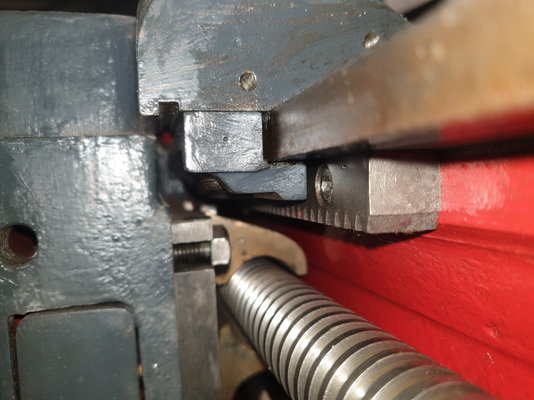

In the back of the carriage you have these 3 bolts (two from below one from above) but these only clamp the carriage down on the bed, the bolts in the front and back can be tightened maximum, when you then tighten the bolt in the middle you adjust how easily the carriage moves back n forth up until the point it cant move at all.

In the front of the carriage it's the same deal, there are 4 bolts and 2 metal pieces that clamp the carriage down vertical, but nothing as far as i can see to adjust rotation.

Thanks, Christof.

beginner here, old lathe which works ok when turning od or driling out stock, however when turning inside diameter the results are terrible.

I've noticed there is a bit of play in the carriage (see picture) however i cant find any way to adjust this rotational play, there are no gibs or anything. Is there any way to fix this problem or are the ways/prisma just worn down and is this lathe ready to be scrapped?

As a test i tightende the gibs in the cross and the top slide completely to eliminate them as the source of the chatter, results were still the same.

I can rotate the carriage like the arrows ever so slightly, you can also see it move when i engage the drive. I suspect this is the source of the chatter when doing inside turning.

In the back of the carriage you have these 3 bolts (two from below one from above) but these only clamp the carriage down on the bed, the bolts in the front and back can be tightened maximum, when you then tighten the bolt in the middle you adjust how easily the carriage moves back n forth up until the point it cant move at all.

In the front of the carriage it's the same deal, there are 4 bolts and 2 metal pieces that clamp the carriage down vertical, but nothing as far as i can see to adjust rotation.

Thanks, Christof.