DennisCA

Member

- Messages

- 1,921

- Location

- Finland

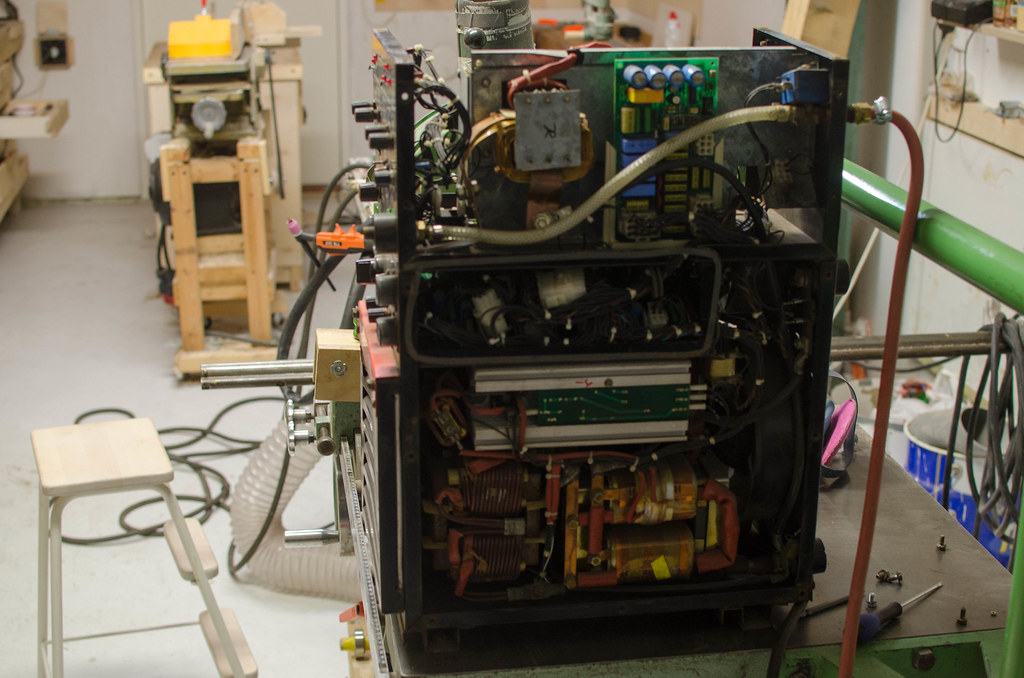

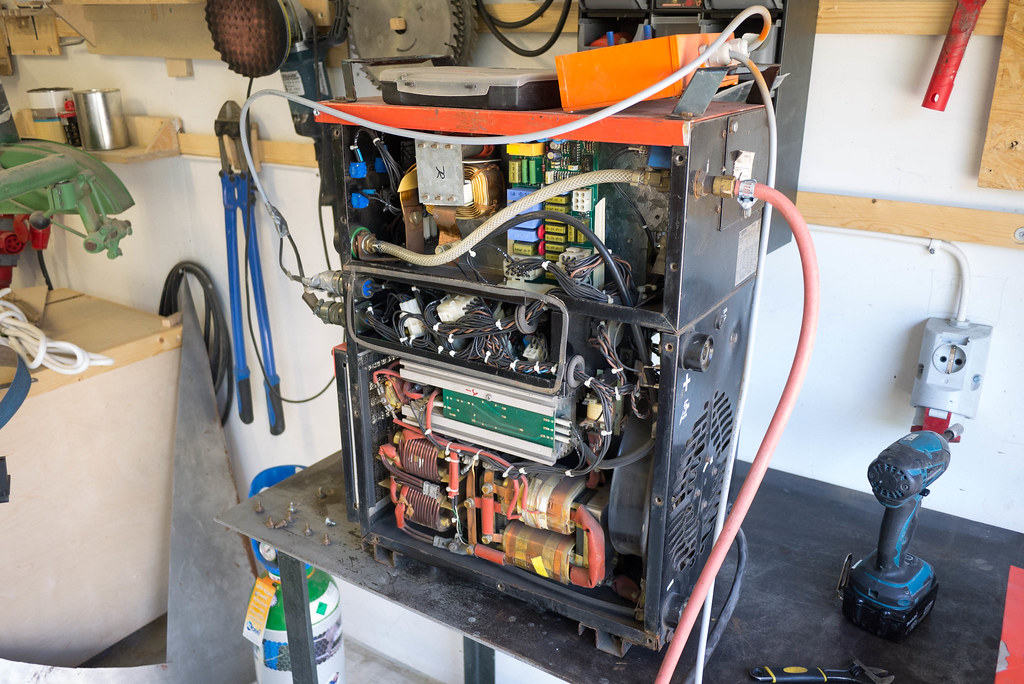

Been inquiring about this machine (page in finnish)

http://www.nettikone.com/kemppi/minarc-300-tig/1527467

The seller finally responded, turns out it's a company called Hemax welding and it's their old machines they're selling off so who knows if they're worn out or not if they have been in professional use. The price 500€ is excluding vat. They'll test the machine that it works before sending it out they say.

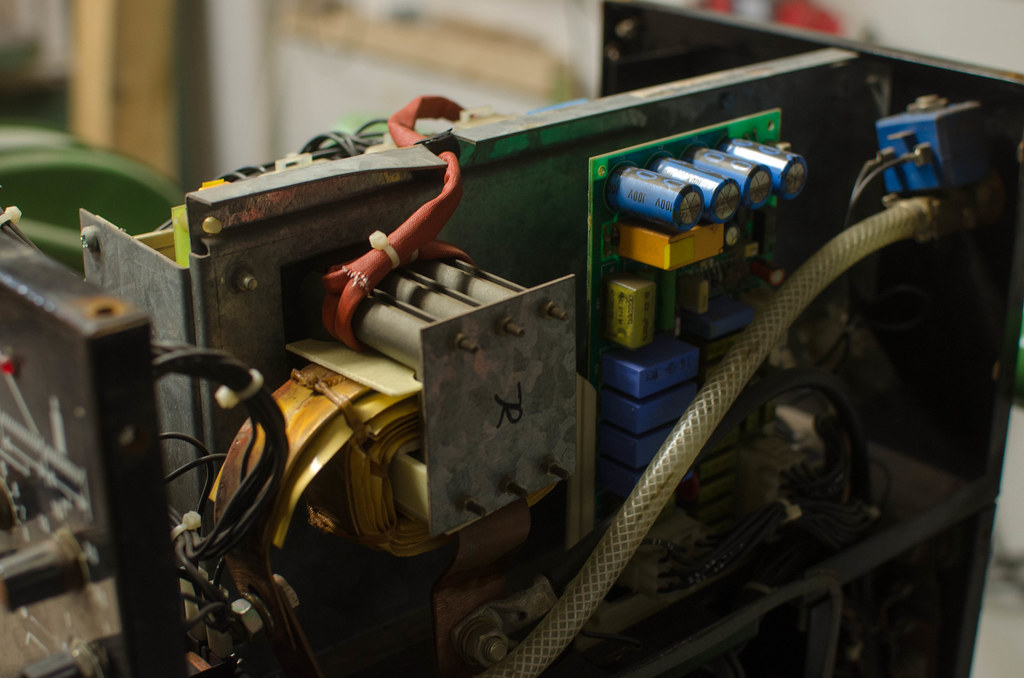

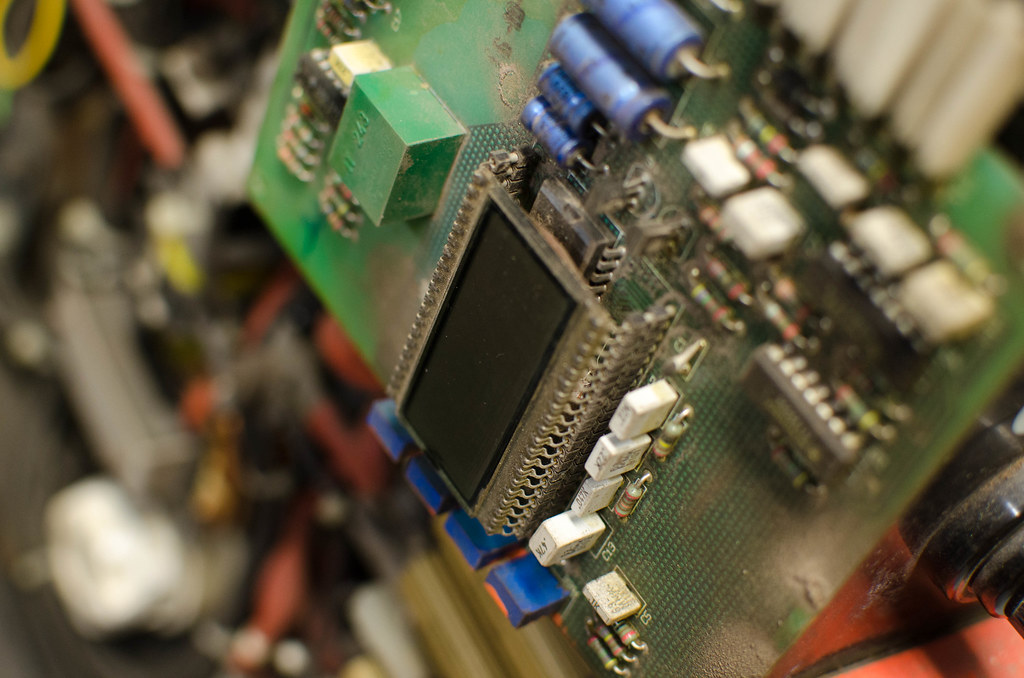

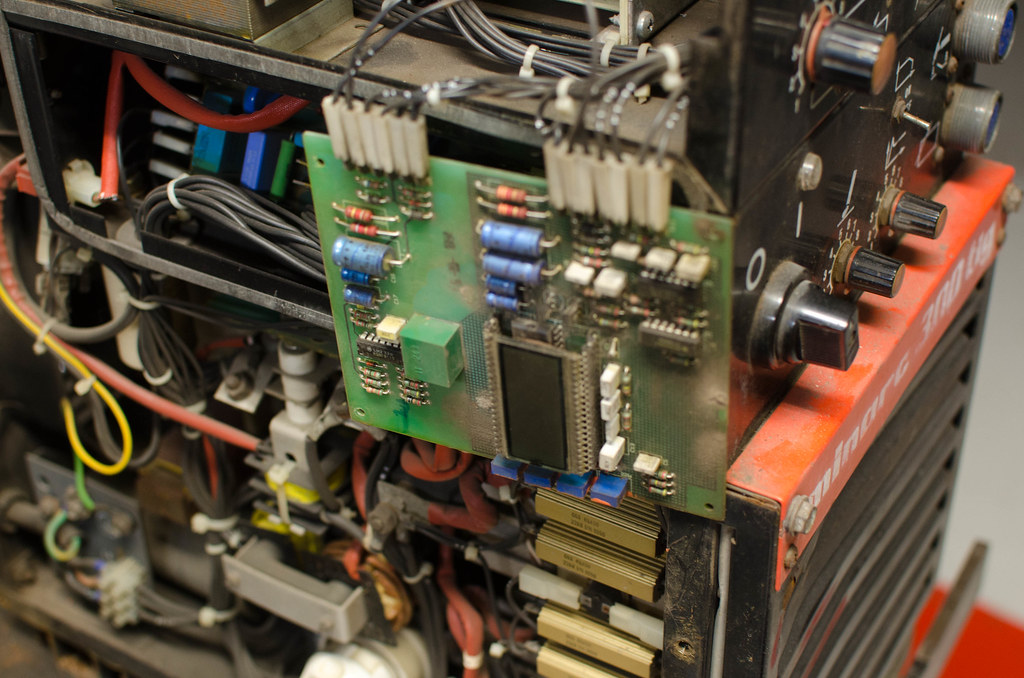

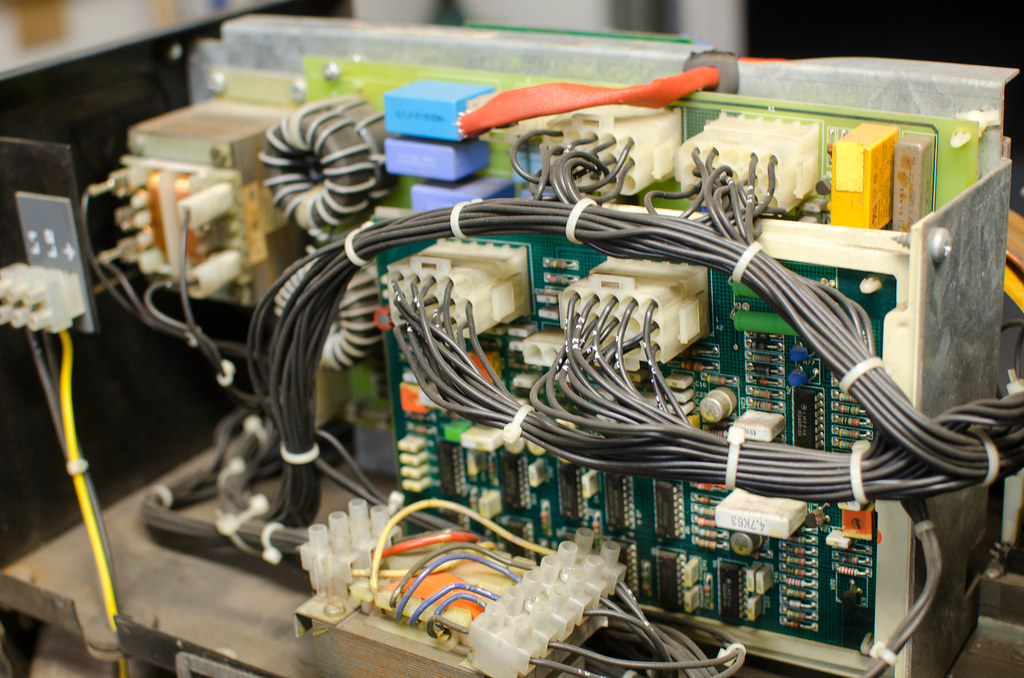

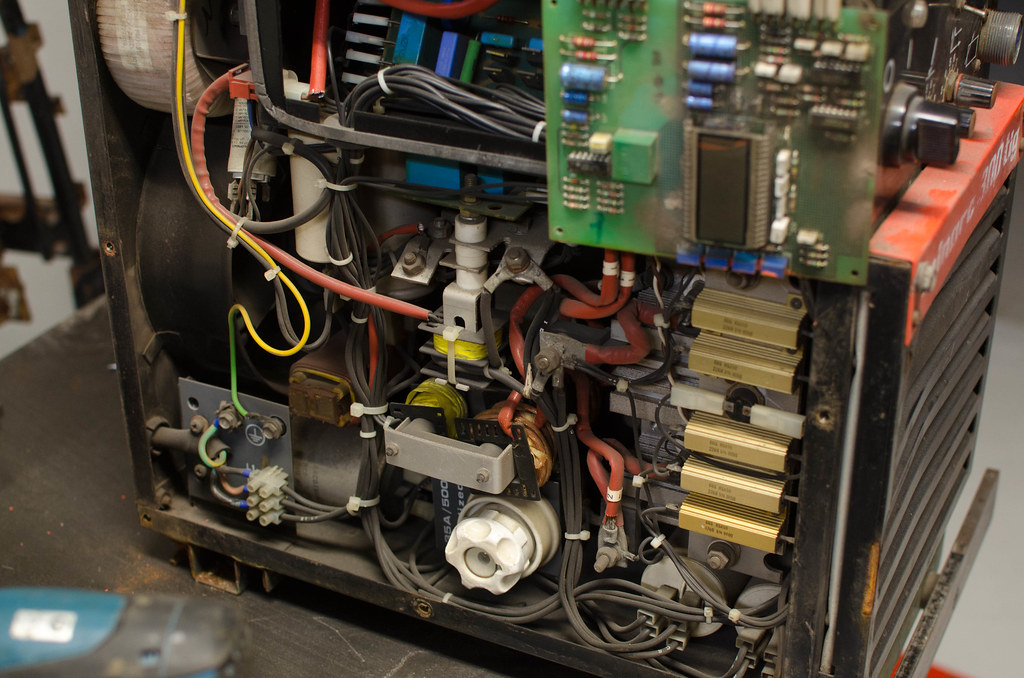

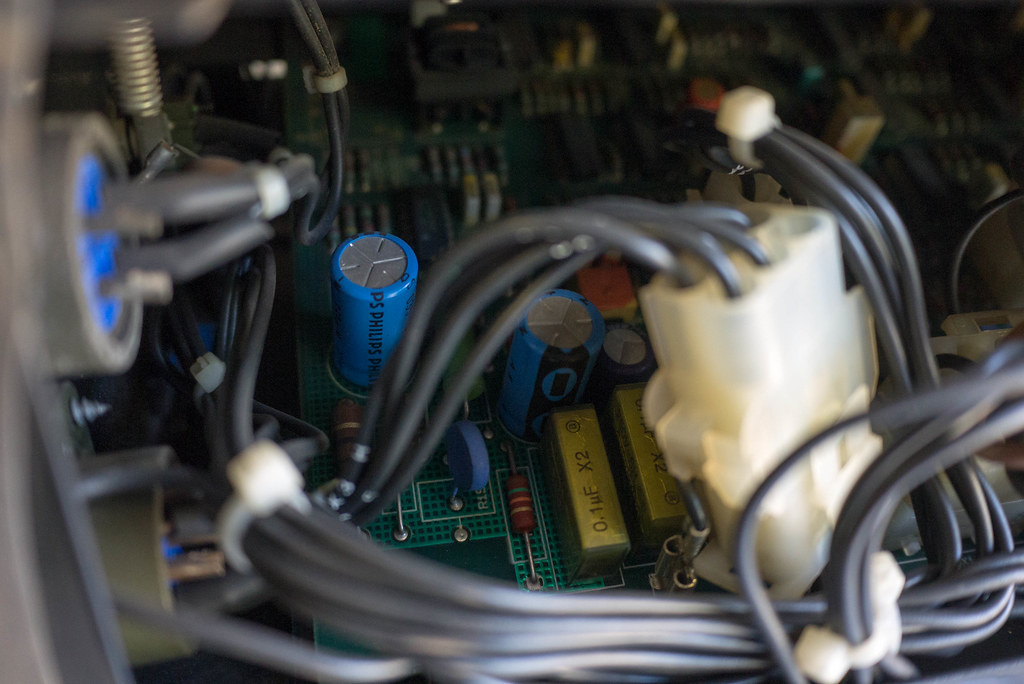

Seems like a pretty beefy machine, with HF start and slope functions, MMA welding up to 270A and TIG 280A. 100% duty cycle up to 150A. I doubt for my purposes I'll cross 150A... Good thing about the design is that it has air filters so the insides should be better protected than most shop machines.

I dunno really, 500 was OK I might chance an older machine... Still, seems welders are more expensive here in Finland.

I got a pretty good offer for a new minarc 200 EVO TIG from rapidwelding.co.uk with CK17 torch retrofitted & free shipping for roughly 1280€+vat.

http://www.nettikone.com/kemppi/minarc-300-tig/1527467

The seller finally responded, turns out it's a company called Hemax welding and it's their old machines they're selling off so who knows if they're worn out or not if they have been in professional use. The price 500€ is excluding vat. They'll test the machine that it works before sending it out they say.

Seems like a pretty beefy machine, with HF start and slope functions, MMA welding up to 270A and TIG 280A. 100% duty cycle up to 150A. I doubt for my purposes I'll cross 150A... Good thing about the design is that it has air filters so the insides should be better protected than most shop machines.

I dunno really, 500 was OK I might chance an older machine... Still, seems welders are more expensive here in Finland.

I got a pretty good offer for a new minarc 200 EVO TIG from rapidwelding.co.uk with CK17 torch retrofitted & free shipping for roughly 1280€+vat.