The project that is driving me to learn MIG welding is to restore (rebuild actually) the body of a 3/4 tonne military Land Rover trailer.

The construction appears to be a frame made of angle ‘iron’ with flat panneling. The project trailer is so rotted out that details such as how the corner joints were done are lost.

So, two questions....

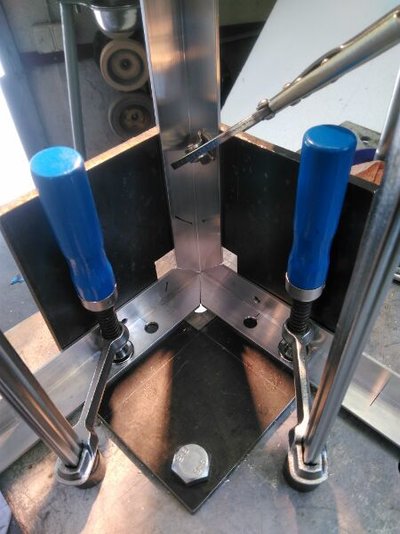

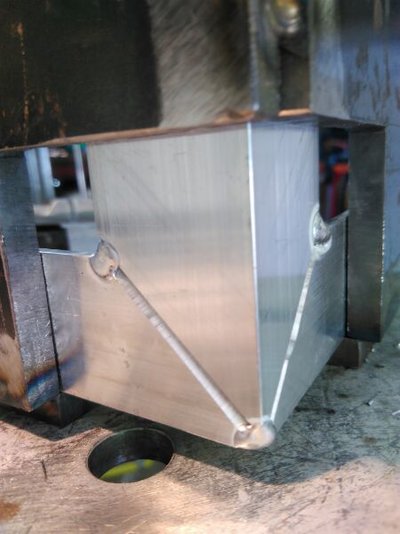

Firstly, for the corner joints of the frame, is the easiest approach to do three-way mitre joints, or is there a better way (it would certainly be easier for me to cut thes than a three-way coping joint).

Secondly, when the panneling is welded to the angle-iron frame, what’s the best way to prevent (or reduce) corrosion between the hidden faces of the frame and panels - or will I just be relying on continuous seams of weld from letting anything in?

Thanks!

The construction appears to be a frame made of angle ‘iron’ with flat panneling. The project trailer is so rotted out that details such as how the corner joints were done are lost.

So, two questions....

Firstly, for the corner joints of the frame, is the easiest approach to do three-way mitre joints, or is there a better way (it would certainly be easier for me to cut thes than a three-way coping joint).

Secondly, when the panneling is welded to the angle-iron frame, what’s the best way to prevent (or reduce) corrosion between the hidden faces of the frame and panels - or will I just be relying on continuous seams of weld from letting anything in?

Thanks!