JimM

Member

- Messages

- 394

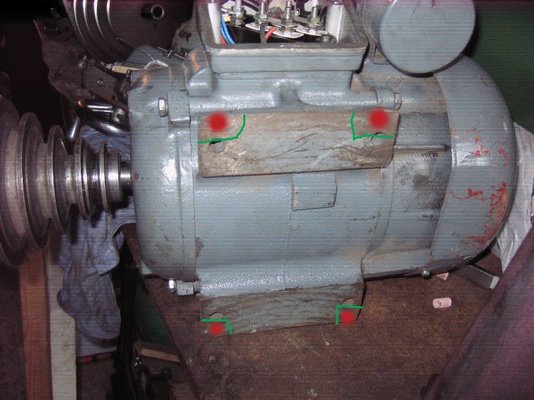

I need some advice about a motor swap I'm doing on my milling machine. The old motor had a larger foot than the replacement and the mounting holes therefore do not line up.

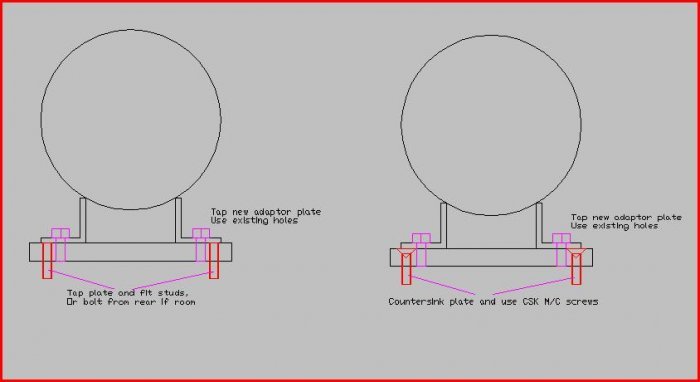

No problem I thought, I'd just make a larger foot plate (thanks Jay !) and bolt motor to plate and plate to machine. However just realised that the 2 sets of bolt holes overlap and will interefere with each other

No problem I thought I'd just weld the plate to the motor (this is a welding forum afterall !) However my MIG is only 150A and the plate and motor foot are both 12mm thick ! Obviously I'm not going to get anything like full penetration here but is that going to be a problem ??? The motor hangs upside down and would guess it weighs 10-15Kg, it's a 1HP jobbie and has a bit of a kick when starting.

If I only get half penetration will it be enough to hold everything in place or is it more likely the vibration, torque etc will just rip it loose eventually.

Thanks

Jim

No problem I thought, I'd just make a larger foot plate (thanks Jay !) and bolt motor to plate and plate to machine. However just realised that the 2 sets of bolt holes overlap and will interefere with each other

No problem I thought I'd just weld the plate to the motor (this is a welding forum afterall !) However my MIG is only 150A and the plate and motor foot are both 12mm thick ! Obviously I'm not going to get anything like full penetration here but is that going to be a problem ??? The motor hangs upside down and would guess it weighs 10-15Kg, it's a 1HP jobbie and has a bit of a kick when starting.

If I only get half penetration will it be enough to hold everything in place or is it more likely the vibration, torque etc will just rip it loose eventually.

Thanks

Jim

. The motor has to mount to a flate plate within the machine itself so any additional nuts/bolt heads would foul this.

. The motor has to mount to a flate plate within the machine itself so any additional nuts/bolt heads would foul this.

How do you tell CI from steel

How do you tell CI from steel

(couldn't help it)

(couldn't help it)