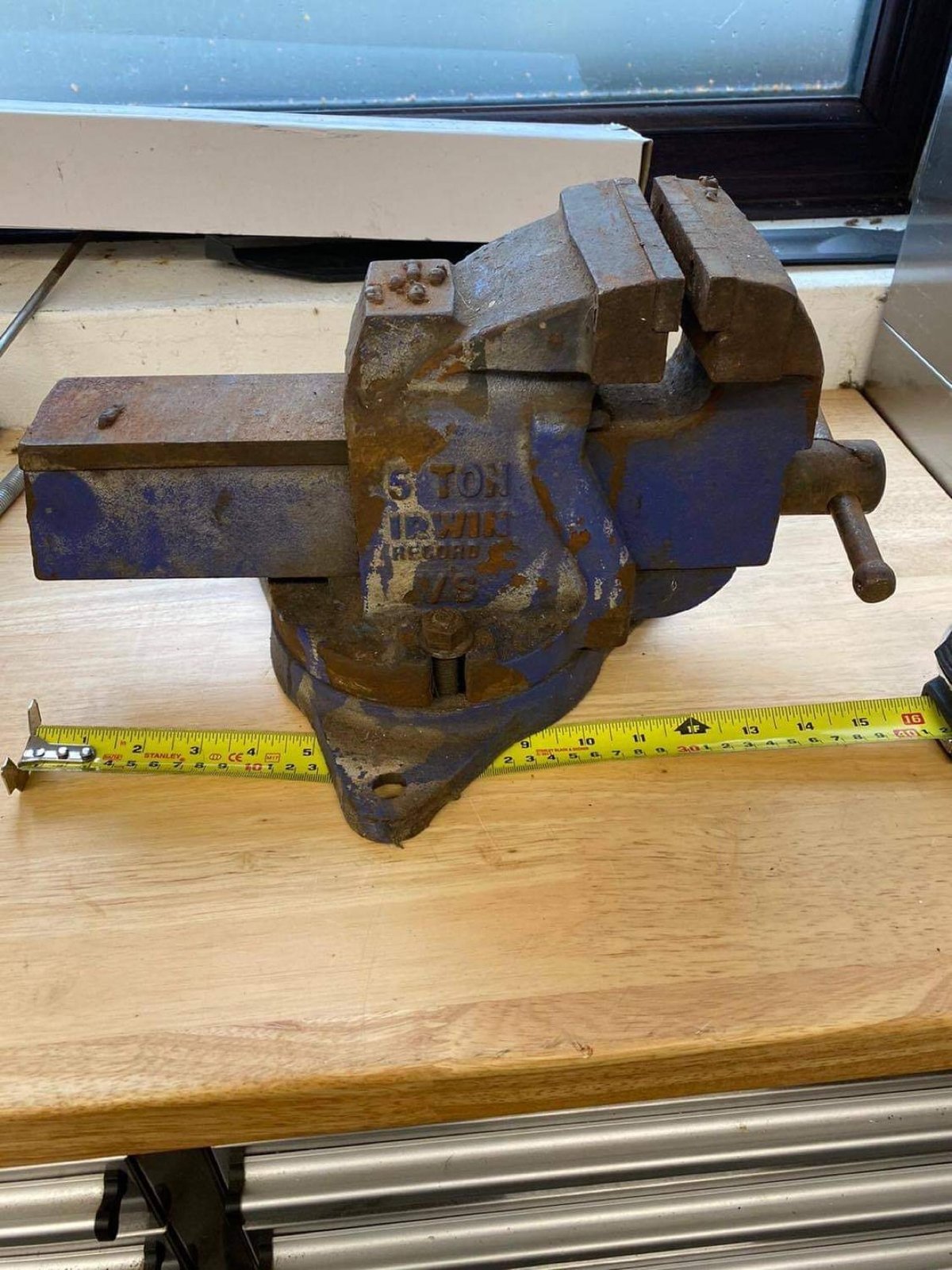

Well here’s another one that I was told about and subsequently offered when collecting a record corner clamp.

It’s not very old and it’s had some animal bend the handle and weld to it

But it was cheap enough and will I think clean up ok and sell on easy enough with a freshen up.

some pics sent by the seller, I’ll update more when I collect it:

thanks as always for looking

It’s not very old and it’s had some animal bend the handle and weld to it

But it was cheap enough and will I think clean up ok and sell on easy enough with a freshen up.

some pics sent by the seller, I’ll update more when I collect it:

thanks as always for looking

I explained to him that that is why the place was always a sh1thole and went and got the Masking Paper, the paint mixing room is like a lunar landscape on the bench too

I explained to him that that is why the place was always a sh1thole and went and got the Masking Paper, the paint mixing room is like a lunar landscape on the bench too