- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Igus Leadscrews/ TR16x2 LH

- Thread starter Kram

- Start date

Kram

Member

- Messages

- 8,332

- Location

- Sussex

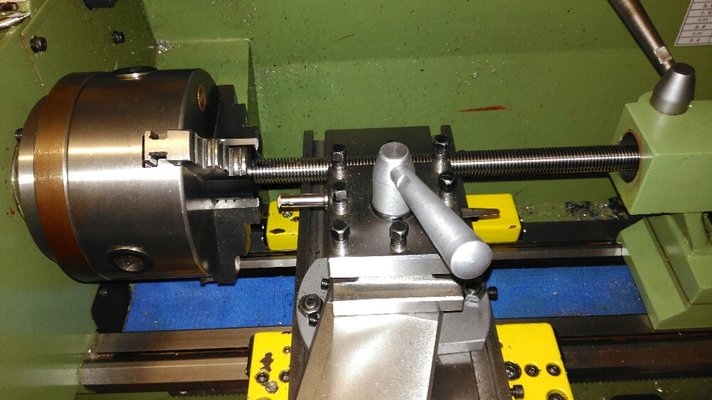

Test fit my leadscrew in nut. Im not taking it out of chuck and Im keeping screw engaged. This is the first thread I have tried to do

I think its nearly done but a tight fit so marker pen on the thread to show me where its tight. Cant get screw out!

I think its nearly done but a tight fit so marker pen on the thread to show me where its tight. Cant get screw out!

Kram

Member

- Messages

- 8,332

- Location

- Sussex

If I made it properly  needs another pass to get it parallel. I need more length so Im going to turn it all down to 7mm and make a split clamp to hold it.

needs another pass to get it parallel. I need more length so Im going to turn it all down to 7mm and make a split clamp to hold it.

Lathe doesnt do 4mm pitch so I need to work out what gears I need for that one. My compound graduations are rubbish and in the wrong place. I might get one of these but I think the V might be too small to be much use. It wont be any good for setting up milling... http://www.ebay.co.uk/itm/272254650845

so I need to work out what gears I need for that one. My compound graduations are rubbish and in the wrong place. I might get one of these but I think the V might be too small to be much use. It wont be any good for setting up milling... http://www.ebay.co.uk/itm/272254650845

needs another pass to get it parallel. I need more length so Im going to turn it all down to 7mm and make a split clamp to hold it.

needs another pass to get it parallel. I need more length so Im going to turn it all down to 7mm and make a split clamp to hold it.Lathe doesnt do 4mm pitch

so I need to work out what gears I need for that one. My compound graduations are rubbish and in the wrong place. I might get one of these but I think the V might be too small to be much use. It wont be any good for setting up milling... http://www.ebay.co.uk/itm/272254650845

so I need to work out what gears I need for that one. My compound graduations are rubbish and in the wrong place. I might get one of these but I think the V might be too small to be much use. It wont be any good for setting up milling... http://www.ebay.co.uk/itm/272254650845