King tom the first

New Member

- Messages

- 4

- Location

- Fleet

Hi, my name is tom and I’m not an alcoholic, hence I’m here at this time on a Friday evening.......

Im looking for input and opinions / facts.

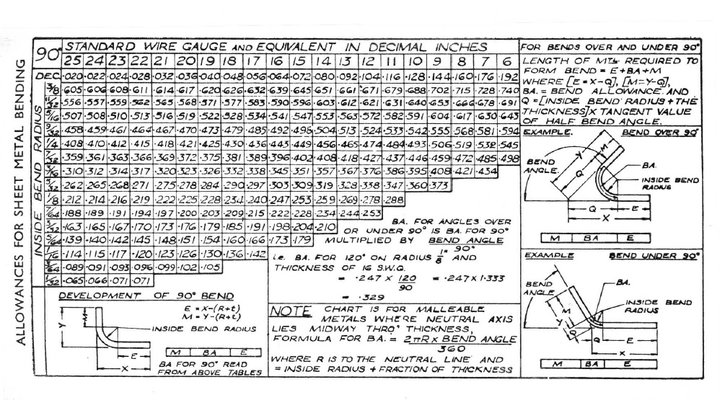

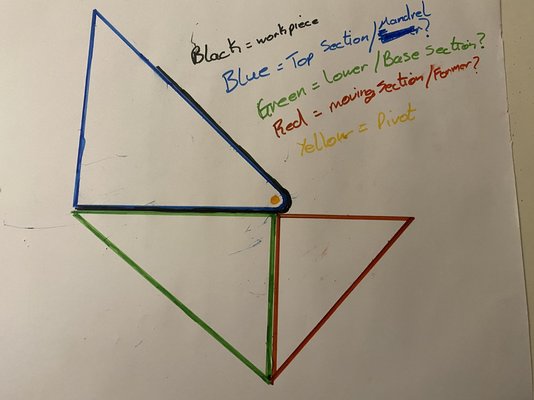

So we are all familiar with the use of angle iron to make a simple sheet metal folding tool.(if not please get yourself up to speed on the concept even if you don’t currently want / care to understand them as I’d like every chance of a sound conclusion!)

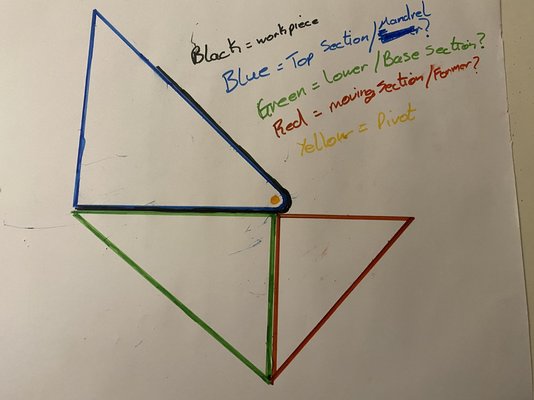

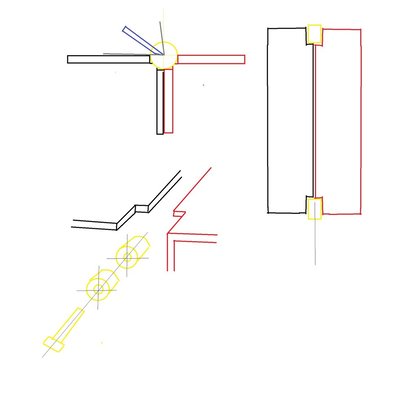

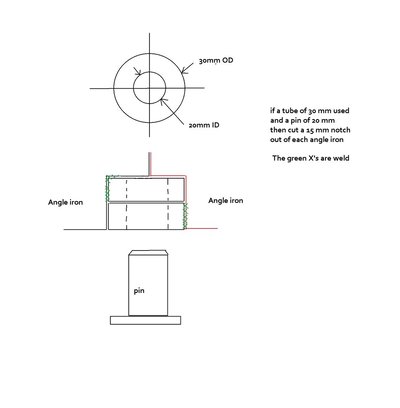

My question is thus, if we are folding the sheet around the edge (say formed to a 1mm radius) of the top section of angle (mandrel?) that is used to clamp the workpiece why is the centre point of the pivot the lower moving part (former?) is swung around not in the centre of the radius we are forming the sheet around?

surely this would give us the best chance of a nice tight radius and consistent bend repeatability? I understand that the top section is normally used to adjust for sheet thickness but this could also be done with the lower moving section if made so. This lower section would also need to be positioned more rearward than traditional so it’s resting position sites it at the centre of the pivot point vertically.

Please refer to my colour coded technical drawing of ultimate professionalismness.

Note: viewed from its end.

cheers chaps, tom.

Im looking for input and opinions / facts.

So we are all familiar with the use of angle iron to make a simple sheet metal folding tool.(if not please get yourself up to speed on the concept even if you don’t currently want / care to understand them as I’d like every chance of a sound conclusion!)

My question is thus, if we are folding the sheet around the edge (say formed to a 1mm radius) of the top section of angle (mandrel?) that is used to clamp the workpiece why is the centre point of the pivot the lower moving part (former?) is swung around not in the centre of the radius we are forming the sheet around?

surely this would give us the best chance of a nice tight radius and consistent bend repeatability? I understand that the top section is normally used to adjust for sheet thickness but this could also be done with the lower moving section if made so. This lower section would also need to be positioned more rearward than traditional so it’s resting position sites it at the centre of the pivot point vertically.

Please refer to my colour coded technical drawing of ultimate professionalismness.

Note: viewed from its end.

cheers chaps, tom.