so ive got given this little job to do.

its a section of my brothers lotus exhaust it has cracked all the way around the weld where a section of pipe comes out the cat.looking at all of the welds none of them have any penetration.

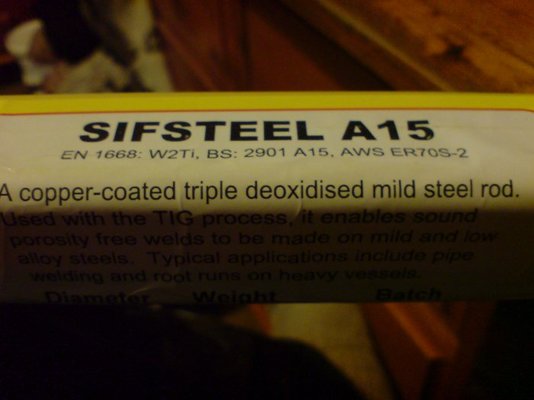

anyway it seems to have been welded with a mig before but i only have a tig to fix it with.in the past when i have tried to tig over mig it has just made the old mig fizz up and then not produce a decent weld.

the tollerences are pretty tight so i cant just wack it back togeter any which way.my query is when i grind off all the old mig how can i make it so that i keep the broken off section in the correct location?

you can see in the pics that i attempted to knock up a half fashoned jig but im going to have to take it all apart to grind off the old welds and that is where i have become stuck.

the cat section is mild steel and the rest is stainless

its a section of my brothers lotus exhaust it has cracked all the way around the weld where a section of pipe comes out the cat.looking at all of the welds none of them have any penetration.

anyway it seems to have been welded with a mig before but i only have a tig to fix it with.in the past when i have tried to tig over mig it has just made the old mig fizz up and then not produce a decent weld.

the tollerences are pretty tight so i cant just wack it back togeter any which way.my query is when i grind off all the old mig how can i make it so that i keep the broken off section in the correct location?

you can see in the pics that i attempted to knock up a half fashoned jig but im going to have to take it all apart to grind off the old welds and that is where i have become stuck.

the cat section is mild steel and the rest is stainless