Hi all, I'm using my new Clarke 160TE welder, I used the settings someone posted up before to do some box-section and plate work on my car and now have had a go at welding a diff with it with a bit less success.

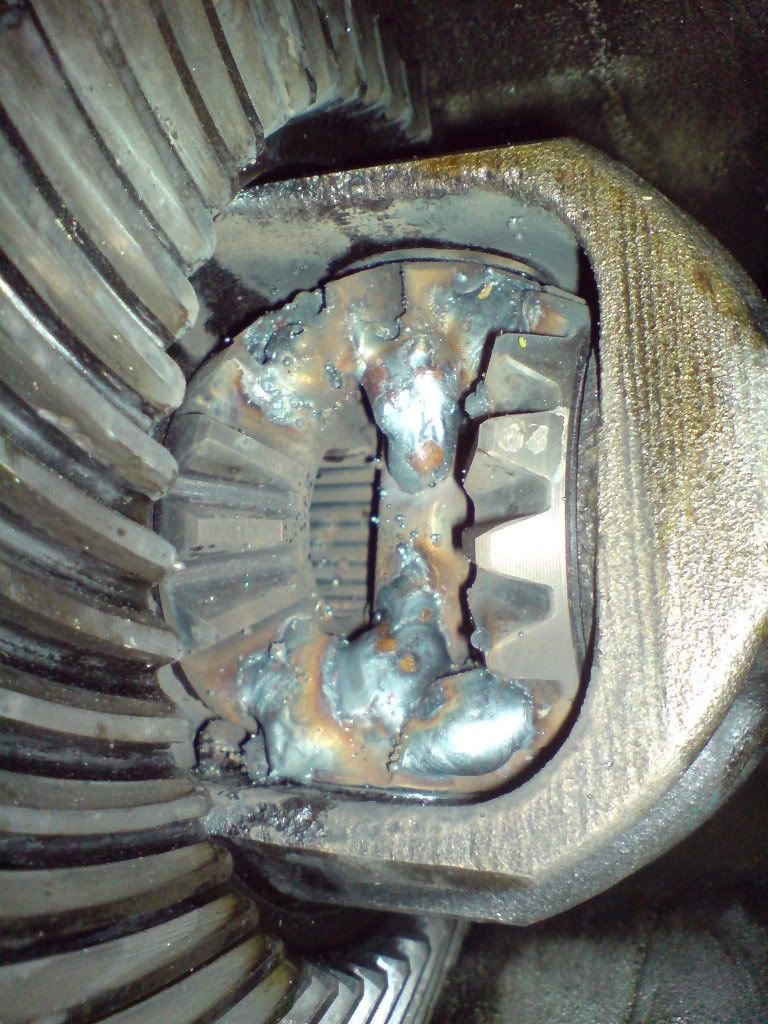

Welding the diff on a car, for those who don't know, is to lock both rear wheels so they spin together, great for drag racing, great for drifting You weld the 4 inner cogs together as best you can to keep them from twisting in opposite directions.

You weld the 4 inner cogs together as best you can to keep them from twisting in opposite directions.

I encountered splatter, and some dark sooty welds with little penetration when everything was set to full.... So I turned it down to 3 - Low (3 - High is max), and 8 on wire feed (out of 10). It seemed to weld nicely but I still have a lot of splatter and it's far from perfect. Looking at it in reality it doesn't look bad, the gears melted away and the welds seem to be filleted into the parent metal at the edges mostly which indicates proper penetration.

Can anybody with more experience offer any advice to me? Perhaps I just didn't clean it well enough or held the torch too far away or something, access is tricky but with some cotton buds etc I could clean it better maybe. It was filled with oil but I washed thoroughly with white spirit and a brush, then wiped clean with blue roll, then rinsed with fairy liquid and water for ages, then more blue roll, then I tried intricately cleaning the gears I was to weld, there seemed to be a slight glaze of moisture on the surface of the teeth of the gears but generally it looked clean.

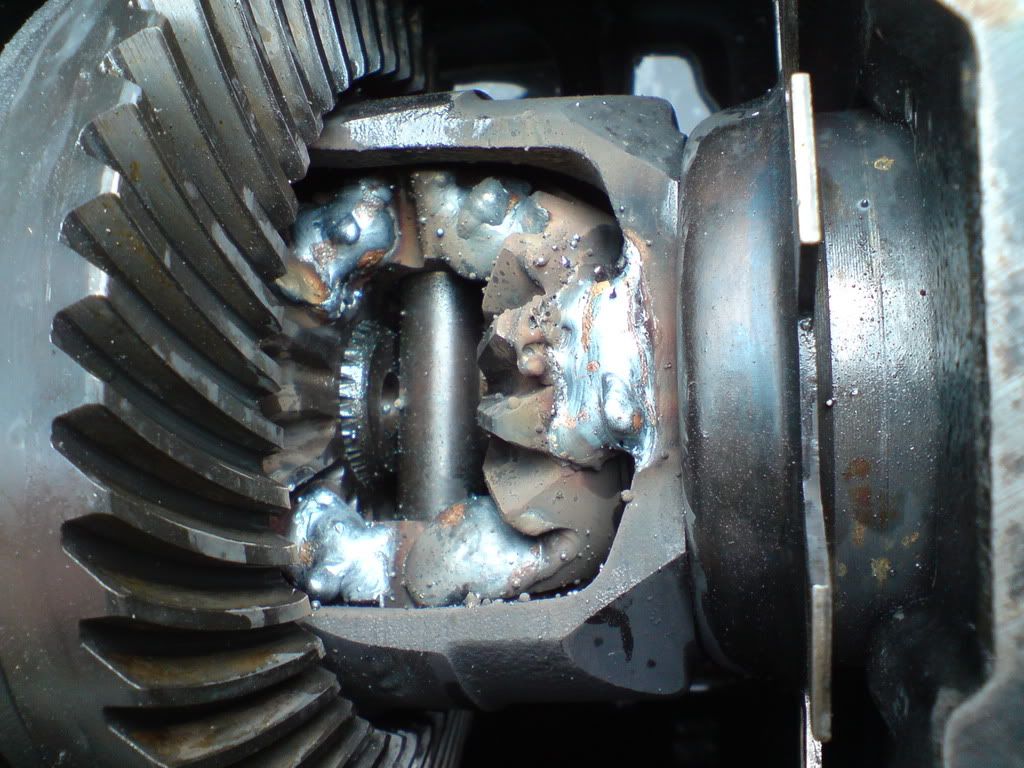

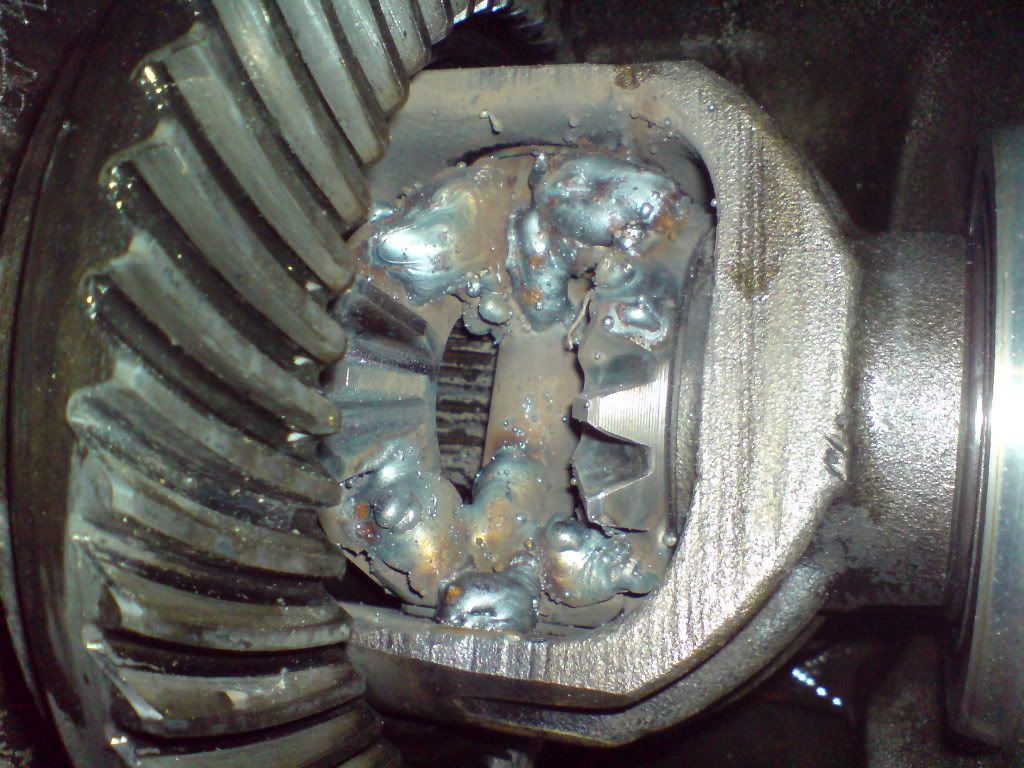

This picture shows it before final drying...

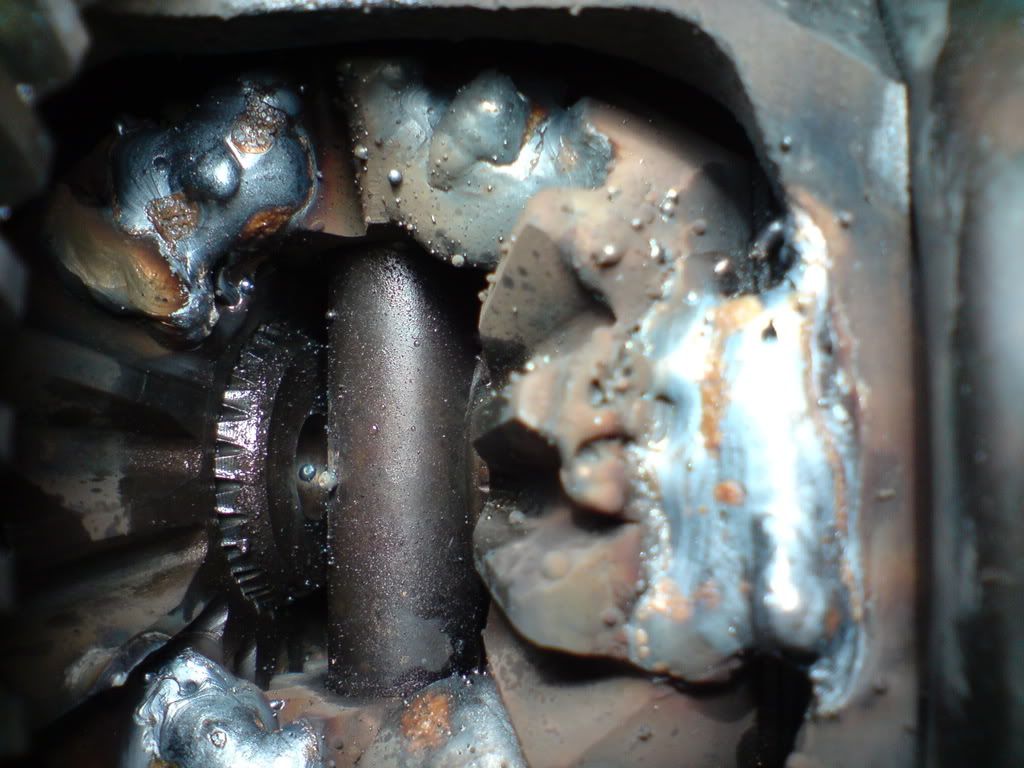

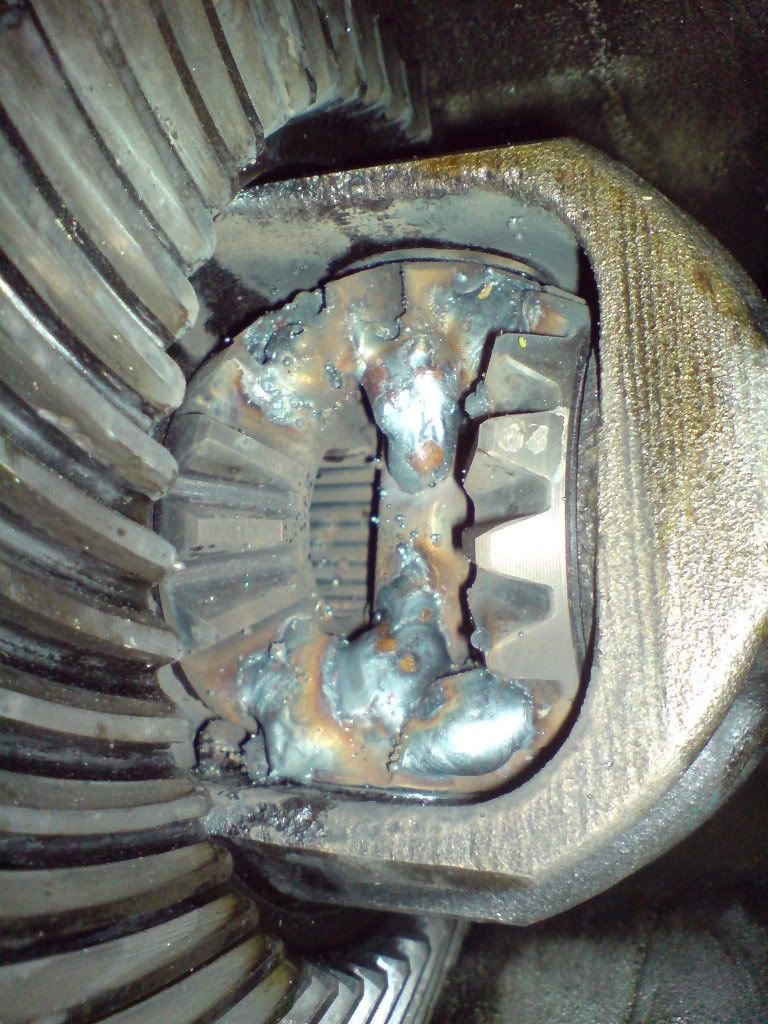

This is the first side (top right corner is where I got settings really bad to start so had to go over it)...

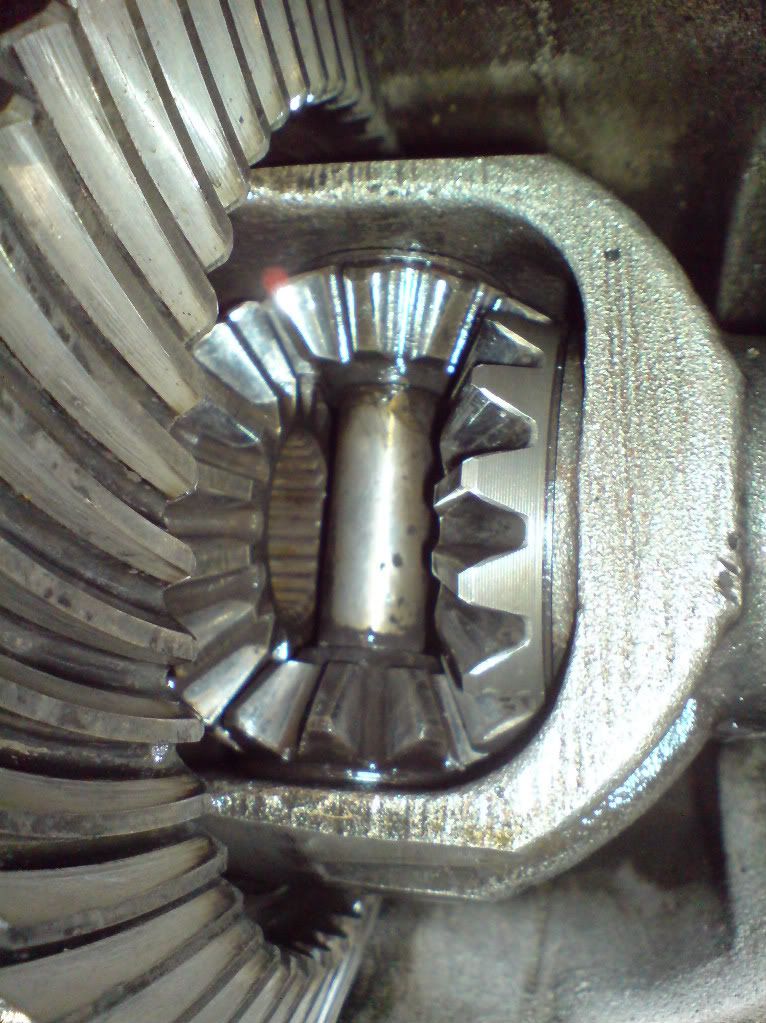

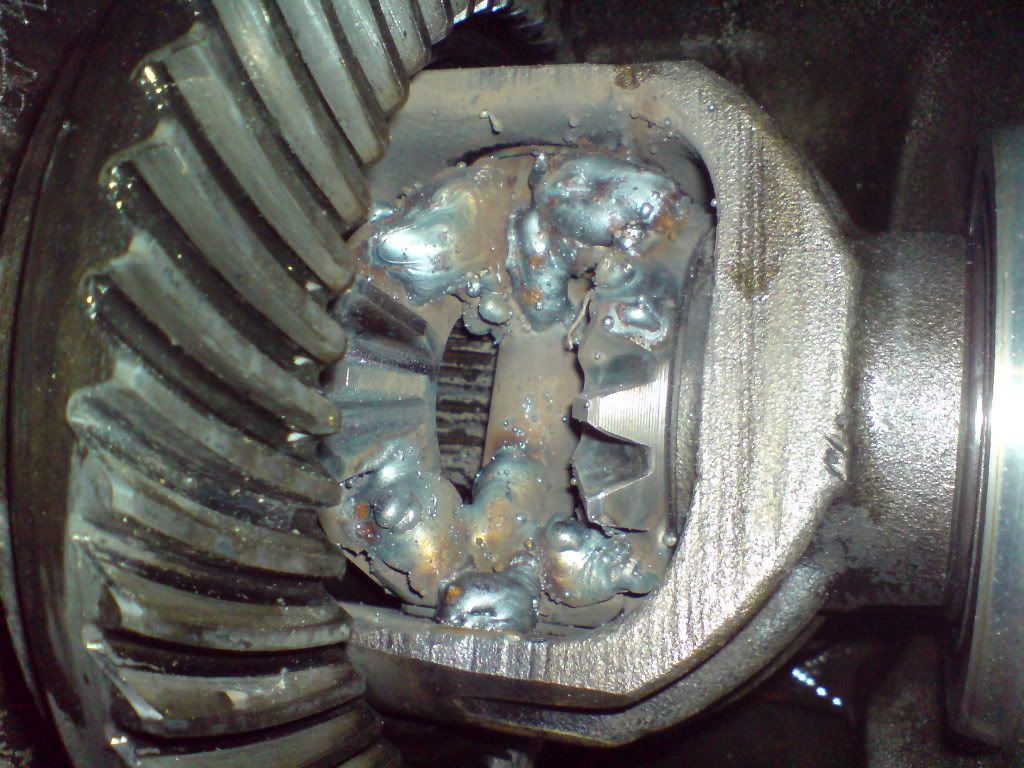

This is the 2nd side...

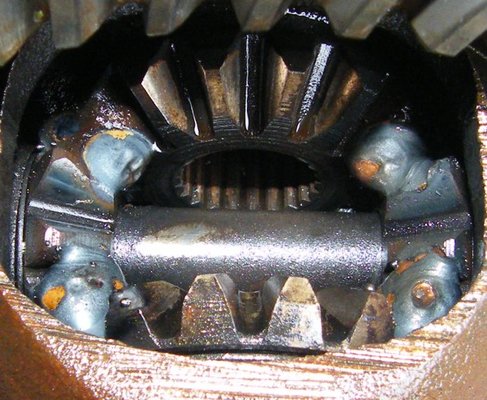

Any advice please on my welds? No advice on welded diffs as I love them and they are CHEEEAP.

Welding the diff on a car, for those who don't know, is to lock both rear wheels so they spin together, great for drag racing, great for drifting

You weld the 4 inner cogs together as best you can to keep them from twisting in opposite directions.

You weld the 4 inner cogs together as best you can to keep them from twisting in opposite directions. I encountered splatter, and some dark sooty welds with little penetration when everything was set to full.... So I turned it down to 3 - Low (3 - High is max), and 8 on wire feed (out of 10). It seemed to weld nicely but I still have a lot of splatter and it's far from perfect. Looking at it in reality it doesn't look bad, the gears melted away and the welds seem to be filleted into the parent metal at the edges mostly which indicates proper penetration.

Can anybody with more experience offer any advice to me? Perhaps I just didn't clean it well enough or held the torch too far away or something, access is tricky but with some cotton buds etc I could clean it better maybe. It was filled with oil but I washed thoroughly with white spirit and a brush, then wiped clean with blue roll, then rinsed with fairy liquid and water for ages, then more blue roll, then I tried intricately cleaning the gears I was to weld, there seemed to be a slight glaze of moisture on the surface of the teeth of the gears but generally it looked clean.

This picture shows it before final drying...

This is the first side (top right corner is where I got settings really bad to start so had to go over it)...

This is the 2nd side...

Any advice please on my welds? No advice on welded diffs as I love them and they are CHEEEAP.