I've not picked the welder up in a while and been having a bit of trouble with lots of splatter and getting the settings right for 3mm. Grateful for any pointers.

I'm using a Clarke 151EN with 0.8mm wire, CO2/argon mix at 15LTM, I have used a new tip in the welder, the wire is new and clean and I've played around with the tension quite a bit and set up as per the guide on here. The roller is in the correct position for the wire size. I've never had problems with splatter like this before, although I've mostly used 0.6mm wire in the past and can't really remember how I got on with 0.8mm as I've not used it probably for a couple of years.

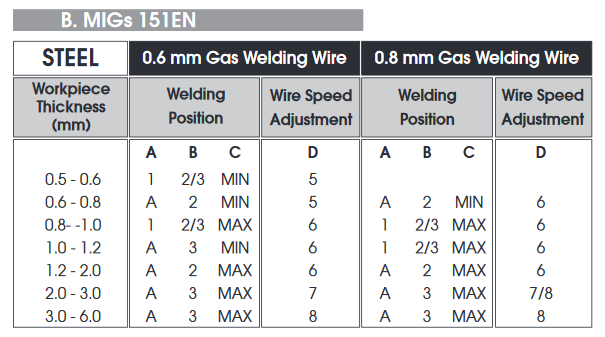

The Clarke has 6 power settings and the manual is as follows:

I've read the threads on here about the Clarke settings and I believe the chart gets the settings mixed up a bit and they should go up as follows:

1 min

1 max

2 min

2 max

3 min

3 max

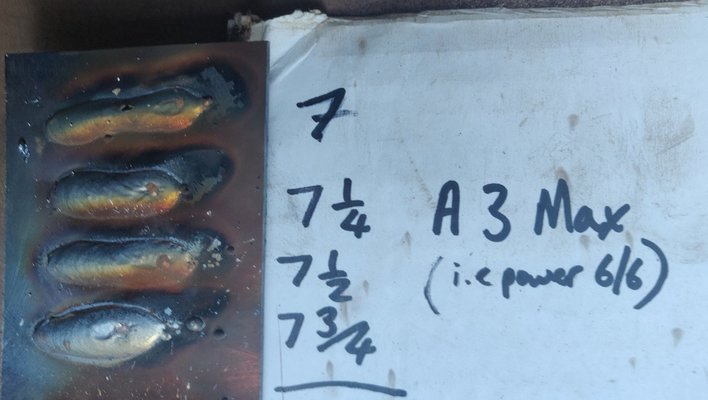

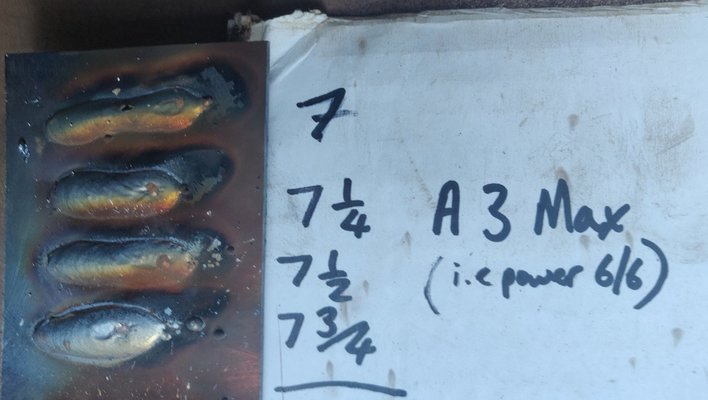

I'm a little lost on what setting to use for 3mm steel, I've done some test runs with A3MAX (i.e. setting 6 out of 6) and A3MIN (i.e. setting 5 out of 6) and I'm getting lots of splatter, this is the result of the highest setting:

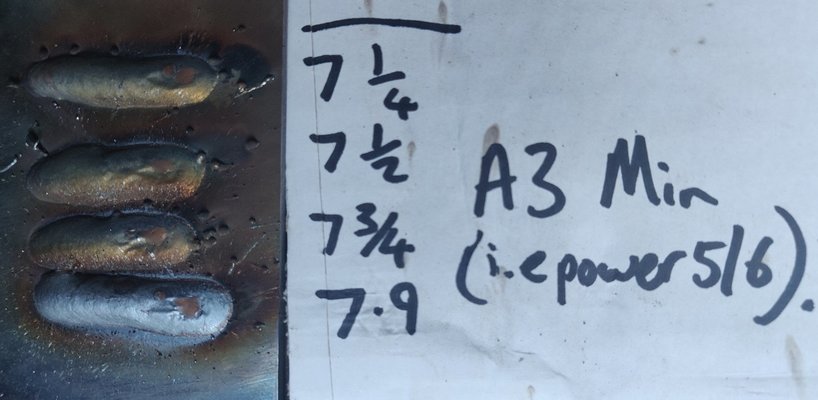

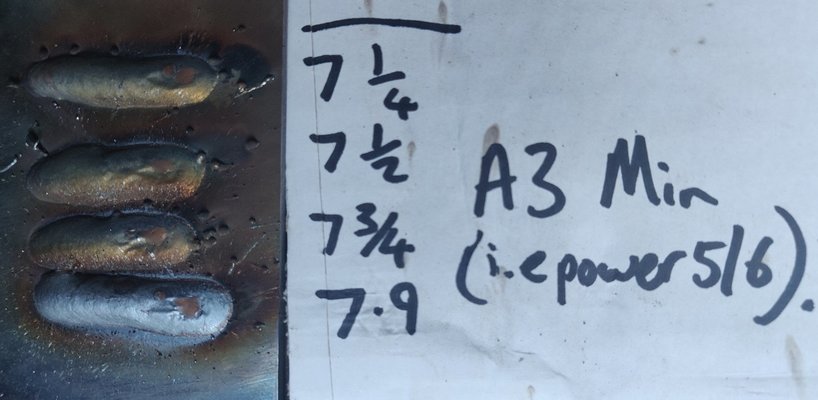

This is the result of the next setting down:

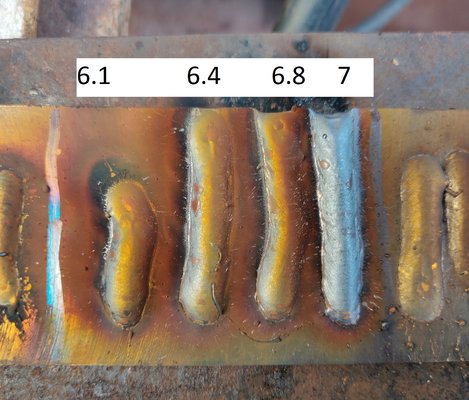

This is the back:

I've filmed some of the runs:

3mm A 3 max 7.75 -

3mm A 3 min 7.25 -

3mm A 3 min 7.5 -

3mm A 3 min 7.75 -

3mm A 3 min 7.9 -

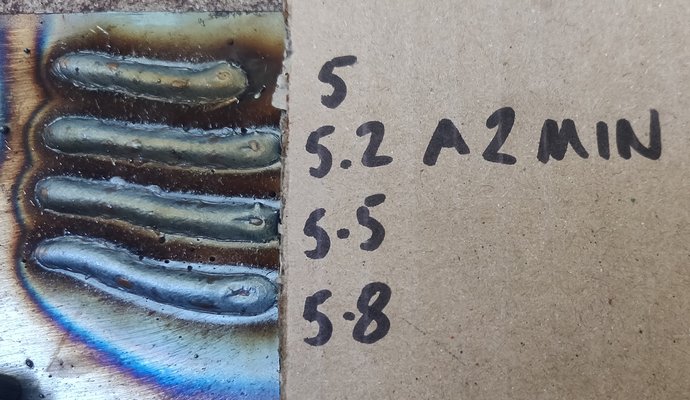

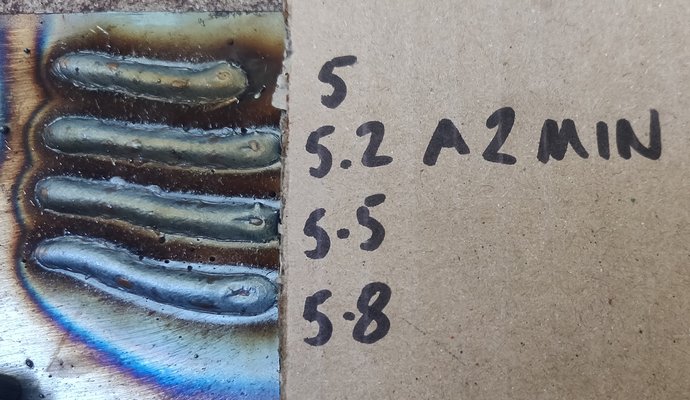

It was late and I was losing patience a bit, my torch position and technique were pretty poor. I also did a few runs on 2mm and had my torch angle a bit better but still got loads of splatter. I have used A2min (i.e. 3 out of 6), can't quite remember why I chose that instead of setting 4 as per the chart but when I looked in my notebook I've had good results with that settings before:

I filmed these as well:

2mm A 2 min 5 - https://youtu.be/jmhV1uCdQXY

2mm A 2 min 5.2 - https://youtu.be/nxJ_wuzy01o

2mm a 2 min 5.5 - https://youtu.be/KlH_5mDpolk

2mm a 2 min 5.8 - https://youtu.be/Fah-DGXx5EU

Any help gratefully received, if I could get an idea of what setting to use on the 3mm I'd feel a bit better practicing and getting my technique a bit better but it's really frustrating me that I can't really work out what setting to use.

I'm using a Clarke 151EN with 0.8mm wire, CO2/argon mix at 15LTM, I have used a new tip in the welder, the wire is new and clean and I've played around with the tension quite a bit and set up as per the guide on here. The roller is in the correct position for the wire size. I've never had problems with splatter like this before, although I've mostly used 0.6mm wire in the past and can't really remember how I got on with 0.8mm as I've not used it probably for a couple of years.

The Clarke has 6 power settings and the manual is as follows:

I've read the threads on here about the Clarke settings and I believe the chart gets the settings mixed up a bit and they should go up as follows:

1 min

1 max

2 min

2 max

3 min

3 max

I'm a little lost on what setting to use for 3mm steel, I've done some test runs with A3MAX (i.e. setting 6 out of 6) and A3MIN (i.e. setting 5 out of 6) and I'm getting lots of splatter, this is the result of the highest setting:

This is the result of the next setting down:

This is the back:

I've filmed some of the runs:

3mm A 3 max 7.75 -

It was late and I was losing patience a bit, my torch position and technique were pretty poor. I also did a few runs on 2mm and had my torch angle a bit better but still got loads of splatter. I have used A2min (i.e. 3 out of 6), can't quite remember why I chose that instead of setting 4 as per the chart but when I looked in my notebook I've had good results with that settings before:

I filmed these as well:

2mm A 2 min 5 - https://youtu.be/jmhV1uCdQXY

2mm A 2 min 5.2 - https://youtu.be/nxJ_wuzy01o

2mm a 2 min 5.5 - https://youtu.be/KlH_5mDpolk

2mm a 2 min 5.8 - https://youtu.be/Fah-DGXx5EU

Any help gratefully received, if I could get an idea of what setting to use on the 3mm I'd feel a bit better practicing and getting my technique a bit better but it's really frustrating me that I can't really work out what setting to use.