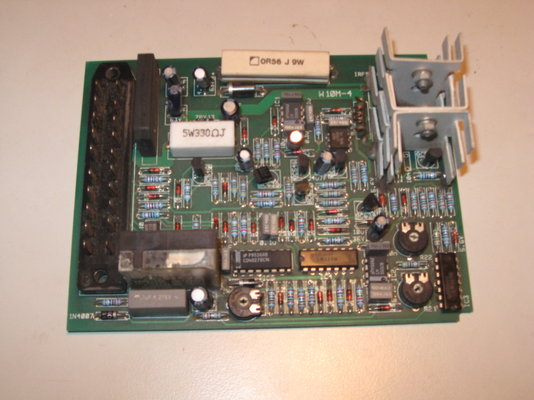

Have retired and want to do a bit of welding Got given a Murex Tradesmig 251 but it has a problem with the wire feed Have a bit of experience with electronics and have traced the fault to the PCB

All pots and switches are OK and I have power to the PCB Contactor clicks but no feed Motor is OK

Has anyone a circuit diagram for this PCB ???

Thanks in advance

JR

All pots and switches are OK and I have power to the PCB Contactor clicks but no feed Motor is OK

Has anyone a circuit diagram for this PCB ???

Thanks in advance

JR