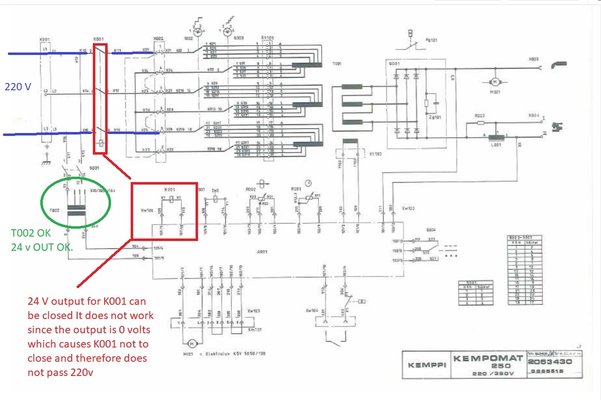

Dear good evening, I am new here looking for help, please be good, I turn to you because I need to be able to operate an old Kempomat 250C machine, the problem is the following described in the attached drawing, the A001 card (4256050) is apparently damaged Because it does not deliver 24 V for K001 to work, the card looks simple but I still can't find the problem or damaged component.

That is why I turn to you, for help I do not know if there is a schematic with the components to be able to make a better review of each component or as a replacement the card to be able to import ... by the way I write to you from Chile here it is practically impossible to get help for these products they are only interested in selling a whole new team, as you will understand that is really depressing.

I hope you can help me.

Best regards.

P.S. sorry for my english i am using google translate.

That is why I turn to you, for help I do not know if there is a schematic with the components to be able to make a better review of each component or as a replacement the card to be able to import ... by the way I write to you from Chile here it is practically impossible to get help for these products they are only interested in selling a whole new team, as you will understand that is really depressing.

I hope you can help me.

Best regards.

P.S. sorry for my english i am using google translate.