Evening All

Found this superb forum about a year ago when thinking about buying a MIG welder, and I'm grateful for the info on here, as it saved me wasting time and money on duff equipment.

I had settled on a Clarke 160TM, but ended up going for the GYS SmartMIG 162, from Weldequip. Steve's customer service was excellent.

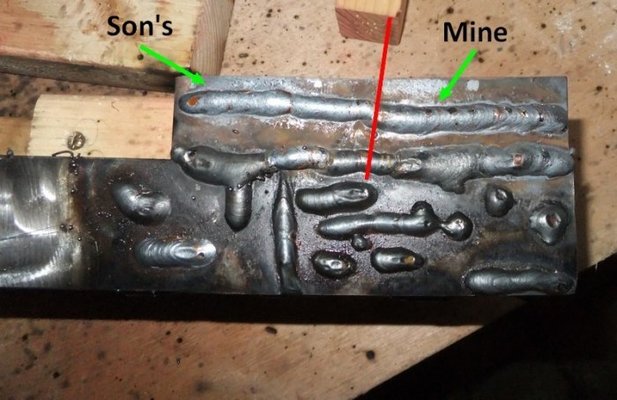

Apart from limited experience with stick welding on a boat trailer nearly 30 years ago, I'm a novice. I've got a mate teaching my lad (14) and I. We had an hour and a half to two hour session on Monday night, and my mate seemed pleased with our last welds of the night. We did half a length each (pic below). We were welding in the back garden, and fortunately there wasn't much of a breeze.

Our initial practise session was using 3mm material, and we'll be moving on to thinner material next session. Probably 1.5mm rectangle box section, which we'll be using for our first proper project we'll be doing with my Dad.

We're using Hobby Gas (9ltr 5% mix) from Adams Gas.

My next challenge will be to make our small workshop welding-proof. Biggest problem is the flooring, which is a light grey lino-type flooring, which has been great up to now. Mostly it's only had to cope with saw-dust. It won't last 2 minutes with welding spatter flying about. I'll probably end up using hard board as a temp cover for now, as welding blankets would be an expensive solution to start with. I don't really want to permanently remove the covering at this stage, but any alternative suggestions would be welcome.

Cheers

Found this superb forum about a year ago when thinking about buying a MIG welder, and I'm grateful for the info on here, as it saved me wasting time and money on duff equipment.

I had settled on a Clarke 160TM, but ended up going for the GYS SmartMIG 162, from Weldequip. Steve's customer service was excellent.

Apart from limited experience with stick welding on a boat trailer nearly 30 years ago, I'm a novice. I've got a mate teaching my lad (14) and I. We had an hour and a half to two hour session on Monday night, and my mate seemed pleased with our last welds of the night. We did half a length each (pic below). We were welding in the back garden, and fortunately there wasn't much of a breeze.

Our initial practise session was using 3mm material, and we'll be moving on to thinner material next session. Probably 1.5mm rectangle box section, which we'll be using for our first proper project we'll be doing with my Dad.

We're using Hobby Gas (9ltr 5% mix) from Adams Gas.

My next challenge will be to make our small workshop welding-proof. Biggest problem is the flooring, which is a light grey lino-type flooring, which has been great up to now. Mostly it's only had to cope with saw-dust. It won't last 2 minutes with welding spatter flying about. I'll probably end up using hard board as a temp cover for now, as welding blankets would be an expensive solution to start with. I don't really want to permanently remove the covering at this stage, but any alternative suggestions would be welcome.

Cheers