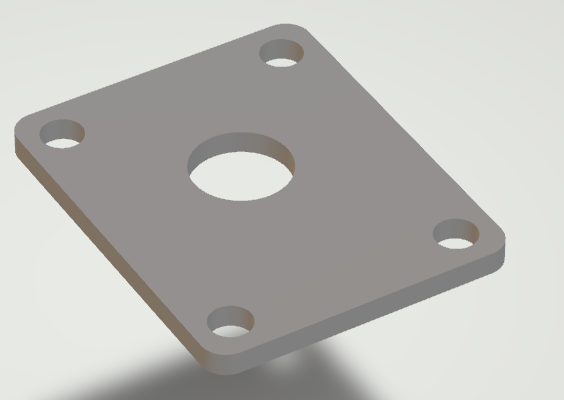

Guy on the Fusion forum kindly converted it and added what I think is a parametric adjustment so I can print and try and adjust as needed.Mesh menu. Modify -> Convert Mesh.

This should then convert the model, with the model shown in black.

To create a solid surface for then sketching on, switch to Surface.

Then Modify -> Merge. With the merge window open, select the two triangles that now make up the side of the holder.

After that, stay in surface, and sketch/extrude your extra bit there.

Which is why I was trying to sort it myself. Screwdriver kindly did the original and got me out of the poo.

But as the weather has got cooler the initial cut seems to have got tougher.

I am hoping the lower angle of attach will reduce the sideways loading causing it not to cut cleanly at times.

This is the forum. In case it helps anyone. https://www.facebook.com/groups/fusion360users/?ref=share

This is the forum

But many thanks for your replies. I will try following that at the weekend as I am sure I will learn something.

At 71 there's not many spares left to play with ).

At 71 there's not many spares left to play with ).

correctly this time. So I can spin up between centers a precision new 3/4 " dia shaft after drilling the pinholes. Will be making up a crotch pad for the tailstock chuck for this little exercise ..I've often wanted one to accurately drill round bars centrally through the diameter so now is the time to make one I guess.

correctly this time. So I can spin up between centers a precision new 3/4 " dia shaft after drilling the pinholes. Will be making up a crotch pad for the tailstock chuck for this little exercise ..I've often wanted one to accurately drill round bars centrally through the diameter so now is the time to make one I guess.