graffian

Seer unto the end of his beard

- Messages

- 3,816

- Location

- gatwick

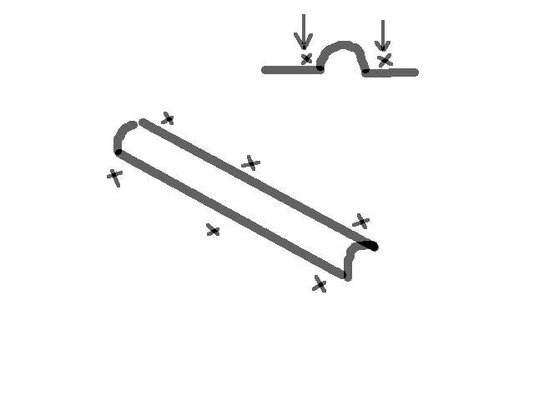

I have to make some landy bulkhead parts and am intending on hammer forming some details.

The first of them are the semicircular section beads in the footwells, 9/16” wide beads about 8” long.

I cut a 16swg steel lowerform, this was to top the lower form and keep the edges crisp. Below that is a 3/16” bit of ply with the beads cut out; and whole lot is topped with a bit of ply with the beads cut out, and this a guide piece.

So my first test piece, well I probably woke lemmy up and this morning i swear some nasty git came round and shoveled a load more bones in my hand, it feels really bad. The bead looked nice but not deep enough-from the top before the bits were all seperated - it was 75 thou off full depth and a half a dizen rounds of hammering hadn’t increased the depth at all. when the wood was all unbolted the metal is no where near flat. I guess I need more thickness of wood, just given away all the wood that was here! For some reason I assumed I would need the lower thickness to make up the required depth, I don’t think it matters to much the bead forms very evenly and doesn’t need to bottom out, and if it did I would add some bitsascrap.

Maybe I need a bigger air hamme? If I was forming with a hammer, and the metal was being obstinate, I would get a bigger hammer; are there different air chisels, without robbing the local roadworks of their alarm clock? I had an elcheapo air chisel that was much heavier, and bigger, then the snap on ones, but it was a whimp compared to them.

I am using 1.2mm, actually .0445” (1.13mm).

hints welcomed.

The first of them are the semicircular section beads in the footwells, 9/16” wide beads about 8” long.

I cut a 16swg steel lowerform, this was to top the lower form and keep the edges crisp. Below that is a 3/16” bit of ply with the beads cut out; and whole lot is topped with a bit of ply with the beads cut out, and this a guide piece.

So my first test piece, well I probably woke lemmy up and this morning i swear some nasty git came round and shoveled a load more bones in my hand, it feels really bad. The bead looked nice but not deep enough-from the top before the bits were all seperated - it was 75 thou off full depth and a half a dizen rounds of hammering hadn’t increased the depth at all. when the wood was all unbolted the metal is no where near flat. I guess I need more thickness of wood, just given away all the wood that was here! For some reason I assumed I would need the lower thickness to make up the required depth, I don’t think it matters to much the bead forms very evenly and doesn’t need to bottom out, and if it did I would add some bitsascrap.

Maybe I need a bigger air hamme? If I was forming with a hammer, and the metal was being obstinate, I would get a bigger hammer; are there different air chisels, without robbing the local roadworks of their alarm clock? I had an elcheapo air chisel that was much heavier, and bigger, then the snap on ones, but it was a whimp compared to them.

I am using 1.2mm, actually .0445” (1.13mm).

hints welcomed.