Gas mark 5

Member

- Messages

- 225

- Location

- Leeds / Harwell, UK

I know nothing about lathes, but keep coming across jobs where it would be handy to have one, so picked this up a while back. Been meaning to put it into service for longer than I care to admit, so hoping a thread here will help spur me into action.

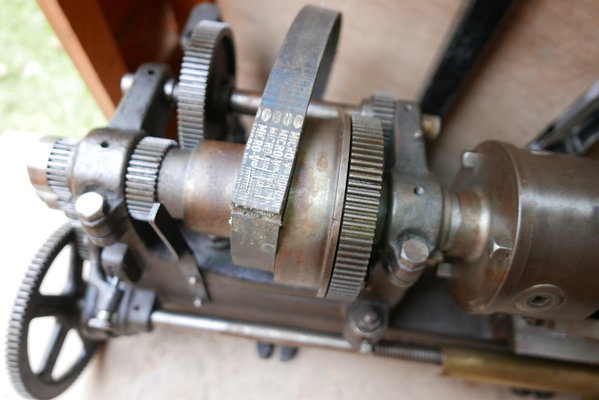

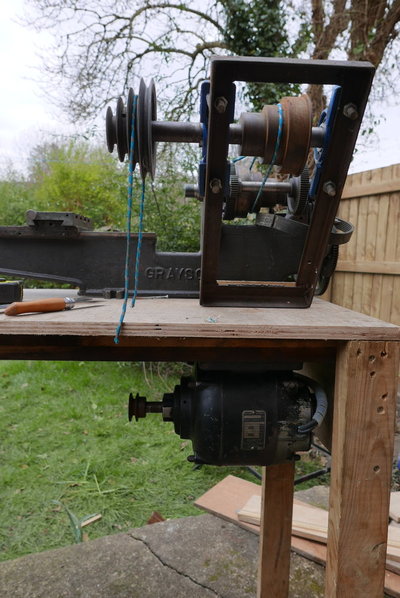

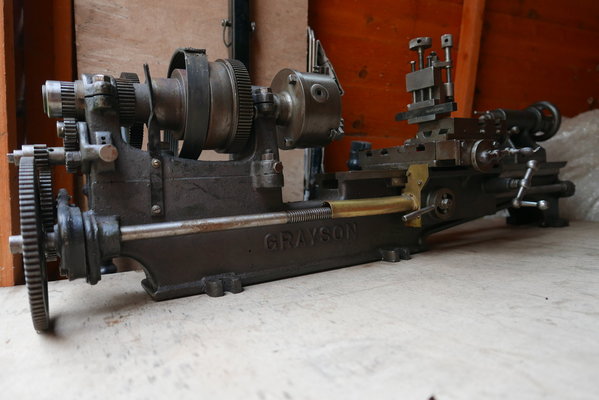

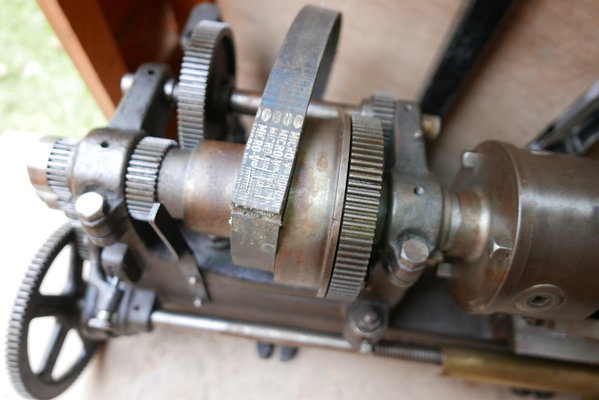

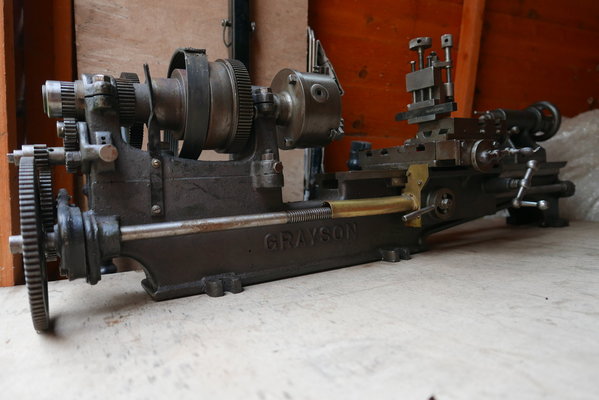

It's a 3.5"x18" Grayson. It seems to my uneducated eye to be in reasonable condition, a few dings here and there, but no heavy wear on the ways, and only a few spots of light surface rust. Came with a three and four jaw chuck, faceplate and a bunch of change wheels. The cross slide jams up halfway, but I suspect it is just dried up oil, and the tailstock is missing a few grubscrews etc. but nothing major I hope. Not planning a full restoration or anything, just want to start making some swarf!

I need to make a bench for it, so the first question for the collective is how important is leveling / mounting surface flatness? I notice the lathes.co.uk description mentions the tailstock feet give the owner "an opportunity to distort things by bolting it to an uneven surface". Is a random sheet of 19mm ply sufficient, or does it need to be precision shimmed, and how would I tell how much shimming is required? Is accurate level sufficient to gauge any twist along the bed?

Thanks in advance all, I'm sure there'll be plenty more questions to come.

P.S. What's a good replacement for an alternator belt and a bunch of staples...?

It's a 3.5"x18" Grayson. It seems to my uneducated eye to be in reasonable condition, a few dings here and there, but no heavy wear on the ways, and only a few spots of light surface rust. Came with a three and four jaw chuck, faceplate and a bunch of change wheels. The cross slide jams up halfway, but I suspect it is just dried up oil, and the tailstock is missing a few grubscrews etc. but nothing major I hope. Not planning a full restoration or anything, just want to start making some swarf!

I need to make a bench for it, so the first question for the collective is how important is leveling / mounting surface flatness? I notice the lathes.co.uk description mentions the tailstock feet give the owner "an opportunity to distort things by bolting it to an uneven surface". Is a random sheet of 19mm ply sufficient, or does it need to be precision shimmed, and how would I tell how much shimming is required? Is accurate level sufficient to gauge any twist along the bed?

Thanks in advance all, I'm sure there'll be plenty more questions to come.

P.S. What's a good replacement for an alternator belt and a bunch of staples...?