lorenzo

Member

- Messages

- 151

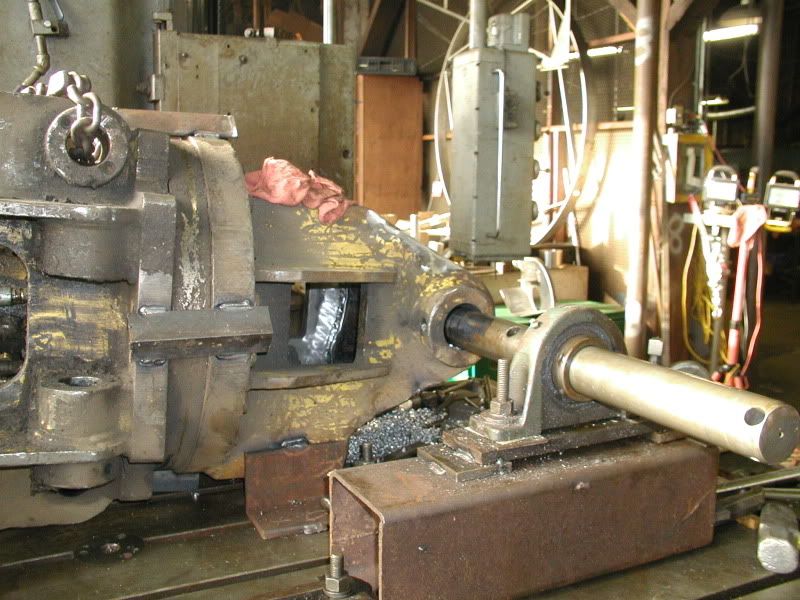

Here is a nice job I did.... I essentialy rebuilt a hydraulic grapple for an excavator that is used in a scrap yard. There were quite a few repairs that needed to be made to this unit so I'll just post stuff in groups....

First is the disassembly. You'll see that the lower pin keeper (pivot point for the tynes) is broken. they all need to be removed and replaced with new ones and the 8 bores need to be repaired.

All the keeprs have been gouged off and all the areas have been cleaned.

Second, I need increase the clearance between the main pin ears at the top of the grapple by a 1/2" and the bores need to be opened up a 1/2' as well.

The boss plates need to be removed from both sides

First is the disassembly. You'll see that the lower pin keeper (pivot point for the tynes) is broken. they all need to be removed and replaced with new ones and the 8 bores need to be repaired.

All the keeprs have been gouged off and all the areas have been cleaned.

Second, I need increase the clearance between the main pin ears at the top of the grapple by a 1/2" and the bores need to be opened up a 1/2' as well.

The boss plates need to be removed from both sides