Pete.

Member

- Messages

- 14,147

- Location

- Kent, UK

I had this gear from a DSG lathe to repair. It had one single busted tooth on it, probably from being dropped as there was no other damage at all. I decided to fit a new piece in and cut the one single tooth with an involute cutter.

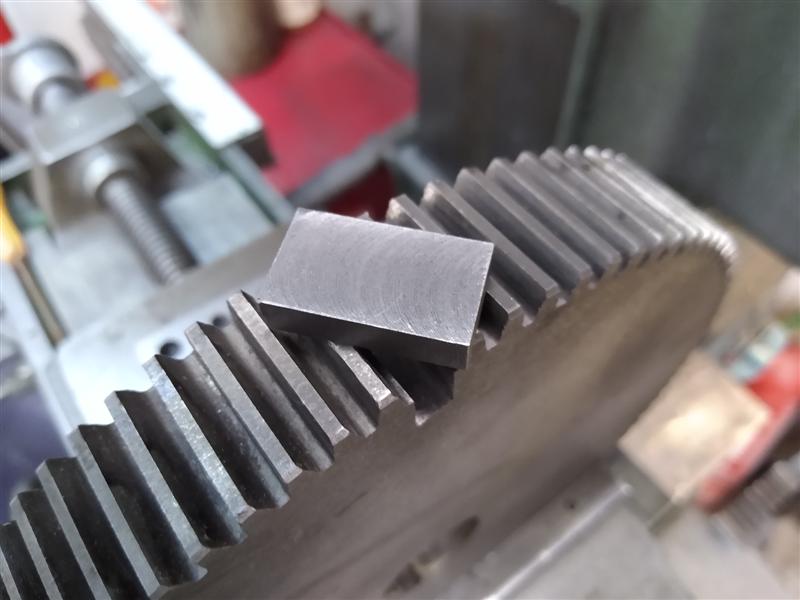

Here's the gear. 90 teeth 12DP 14.5PA. An inch thick with a 1.25" bore. I milled a slot in it where the broken tooth was.

Then I cut a piece from a slab of grey iron I have kicking about for no purpose.

Milled the piece I cut to fit in the slot nice and snug. There were four possible orientations so I picked the best and marked it with an arrow.

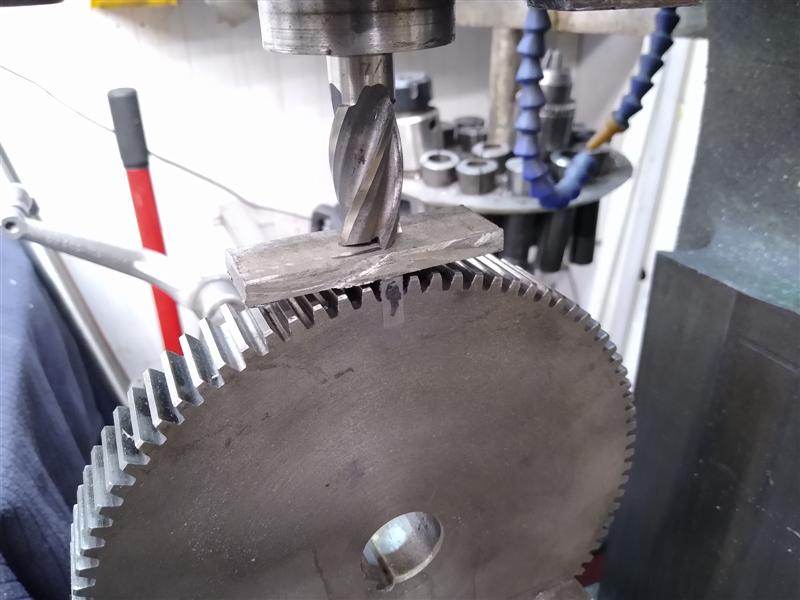

Bonded it in with a high-strength structural araldite. Not your ordinary stuff this is £25 for a small tube. I put it in my mill to keep the load on it for a couple of days of curing. I thought about brazing in the new piece but I wasn't sure if the red heat would affect the grain structure of the adjacent teeth and make them weaker or more brittle. I figured that a good fit and some decent adhesive should hold that piece in very well. I suppose a scotch key could be added for peace of mind, if the owner was worried.

Once the part was cured I stuck in in my chuck to turn the OD. I put a piece of thin card under one jaw with the block dead opposite and this gave it a few thou runout so that I could just turn it down until it skimmed the adjacent teeth half a thou.

Did one half width then turned it around to do the other side.

Gear now ready to have the new tooth cut.

Here's the gear. 90 teeth 12DP 14.5PA. An inch thick with a 1.25" bore. I milled a slot in it where the broken tooth was.

Then I cut a piece from a slab of grey iron I have kicking about for no purpose.

Milled the piece I cut to fit in the slot nice and snug. There were four possible orientations so I picked the best and marked it with an arrow.

Bonded it in with a high-strength structural araldite. Not your ordinary stuff this is £25 for a small tube. I put it in my mill to keep the load on it for a couple of days of curing. I thought about brazing in the new piece but I wasn't sure if the red heat would affect the grain structure of the adjacent teeth and make them weaker or more brittle. I figured that a good fit and some decent adhesive should hold that piece in very well. I suppose a scotch key could be added for peace of mind, if the owner was worried.

Once the part was cured I stuck in in my chuck to turn the OD. I put a piece of thin card under one jaw with the block dead opposite and this gave it a few thou runout so that I could just turn it down until it skimmed the adjacent teeth half a thou.

Did one half width then turned it around to do the other side.

Gear now ready to have the new tooth cut.