my mig welder torch is letting gas out without pressing the trigger and it's live

iv taken the euro conection of and it's still gas flowing out so not the torch

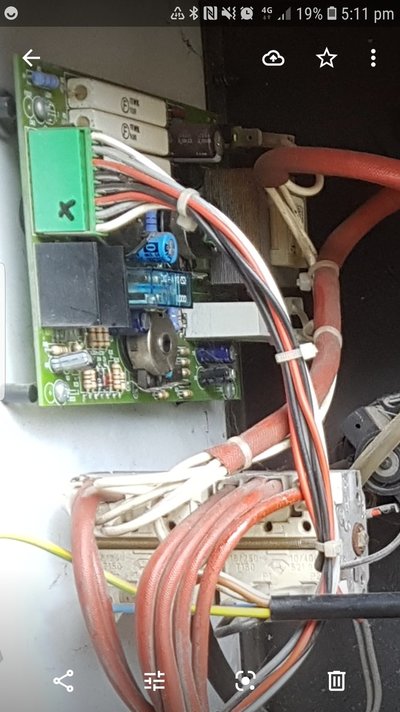

could it be the SOLENOID valve but torch is live

or the contractor

thanks in advance

iv taken the euro conection of and it's still gas flowing out so not the torch

could it be the SOLENOID valve but torch is live

or the contractor

thanks in advance