Henkie Jansen

New Member

- Messages

- 6

- Location

- Netherlands, Utrecht

Hi everyone!

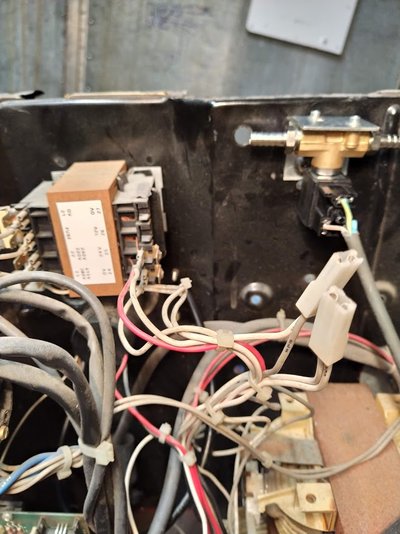

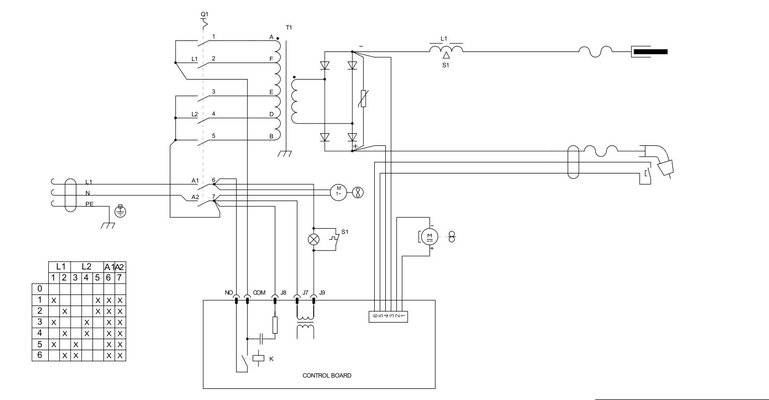

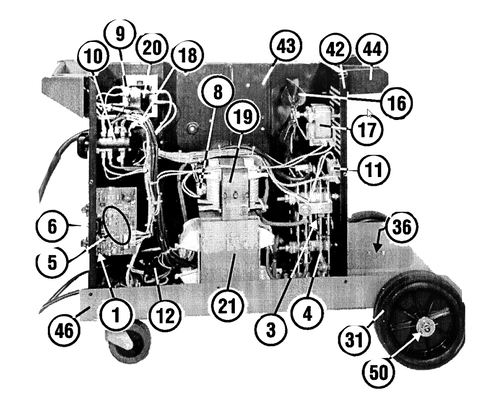

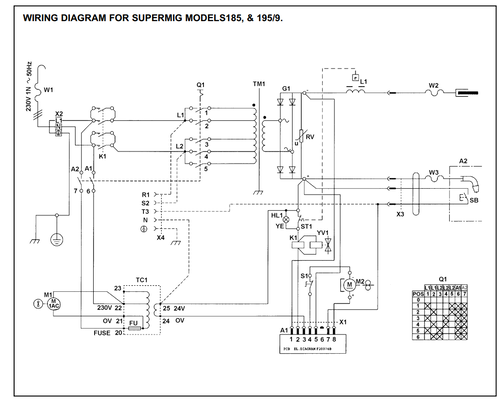

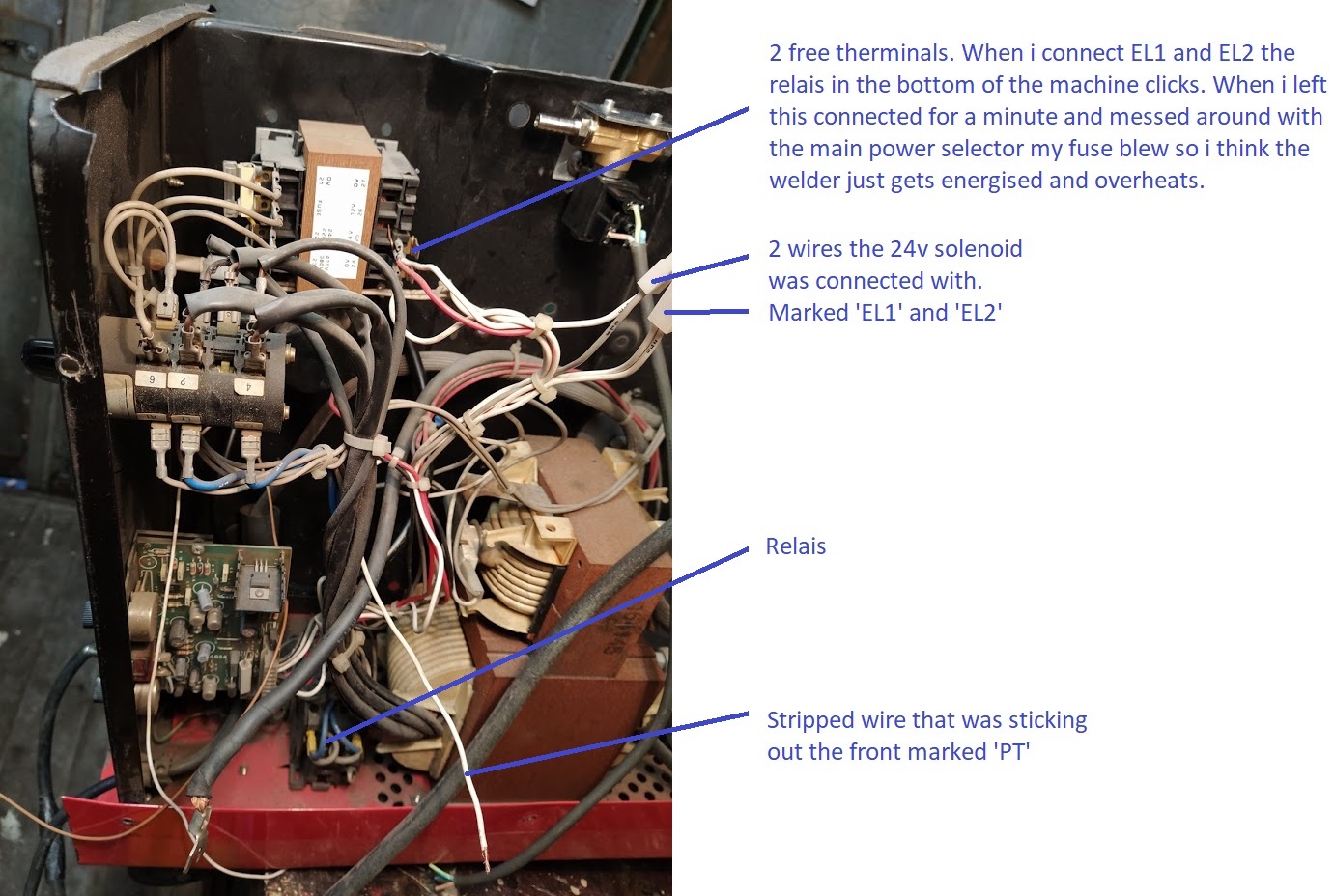

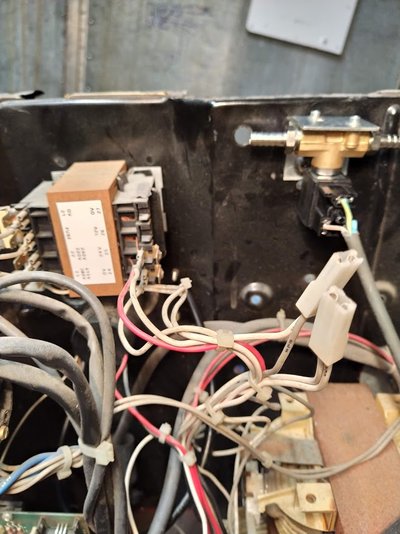

I got a free 180/2 turbo from work a couple weeks ago! The machine wasn't working when i got it and someone had changed some things: there was a 24v solenoid for the gas and there was a stripped wire hanging out. Also the welding gun had a busted up euro connector but the machine had a different connector. When researching the machine i came across this topic: https://www.mig-welding.co.uk/forum/threads/telwin-mig-180-2-convert-to-euro.63036/ about someone converting a 180/2 to euro connector so i ordered a euro connector, new telwin welding gun and a 240v solenoid.

Today i wanted to install the new parts with the information from the topic but i saw that my machine is different. I'm also confused about the the wires the 24v solenoid was connected with and where the stripped wire belongs. Can someone please help?

I got a free 180/2 turbo from work a couple weeks ago! The machine wasn't working when i got it and someone had changed some things: there was a 24v solenoid for the gas and there was a stripped wire hanging out. Also the welding gun had a busted up euro connector but the machine had a different connector. When researching the machine i came across this topic: https://www.mig-welding.co.uk/forum/threads/telwin-mig-180-2-convert-to-euro.63036/ about someone converting a 180/2 to euro connector so i ordered a euro connector, new telwin welding gun and a 240v solenoid.

Today i wanted to install the new parts with the information from the topic but i saw that my machine is different. I'm also confused about the the wires the 24v solenoid was connected with and where the stripped wire belongs. Can someone please help?