Paul G

Member

- Messages

- 932

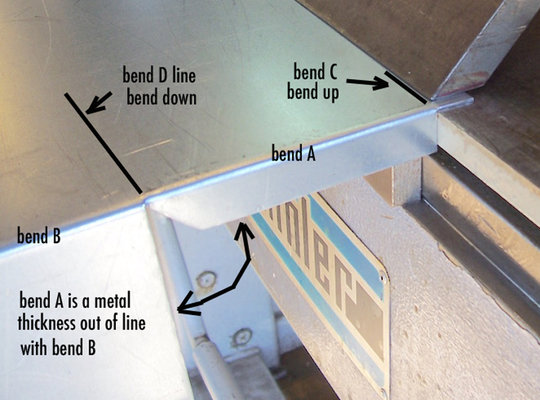

I had some folding to do where folds were a metal thickness out of line, so that when the last fold is done

the spot welding tab slips inside the other surface.

Also one edge is a fold up where as previous folds were fold down. ( See photo's )

Apart from sectional Vee beds on brake presses this is seldom possible on conventional folders.

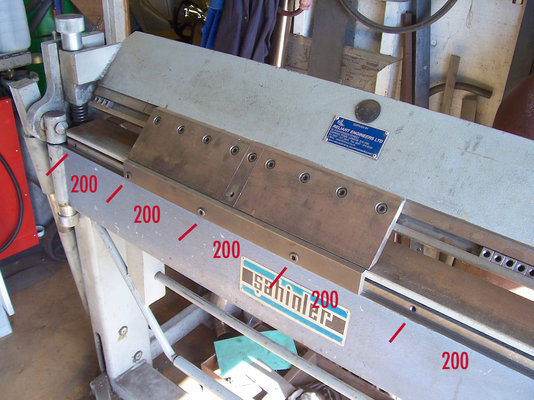

The top fingers on a box & pan are always different sizes and usually tee nuts are used so that any width

can be catered for, but not the bottom bed. I cut some 40 x 12 bright to length to fit this particular job and

it worked so well that I'm now trying to fathom out a way to make a set of bed pieces that would cater for

all lengths of fold. My maths has failed me.

I may be flogging a dead horse.

Paul G

the spot welding tab slips inside the other surface.

Also one edge is a fold up where as previous folds were fold down. ( See photo's )

Apart from sectional Vee beds on brake presses this is seldom possible on conventional folders.

The top fingers on a box & pan are always different sizes and usually tee nuts are used so that any width

can be catered for, but not the bottom bed. I cut some 40 x 12 bright to length to fit this particular job and

it worked so well that I'm now trying to fathom out a way to make a set of bed pieces that would cater for

all lengths of fold. My maths has failed me.

I may be flogging a dead horse.

Paul G