niels

Member

- Messages

- 53

- Location

- Belgium

I'm planning to restore my Citroën 2CV over the coming months (probably years) and it needs a lot of welding at the bodywork. I've zero experience with welding, but I've been always interested in learning the skill. The idea is to build up experience by doing non-car projects (welder cart, small workbench, ...) while working on the car mechanics before attempting to weld the body of the 2CV.

I do have access to a TIG welder (my father-in-law is the son of a retired welding supplies dealer), but after reading and researching it seems that a MIG with a low "starting current" combined with 0.6 mm wire is the way to go for thin sheet (0.8 mm).

I've been searching a lot and trying to read as much as I can about different options. Mind you that I don't live in the UK and it seems that not brands are distributed at this side of the Channel.

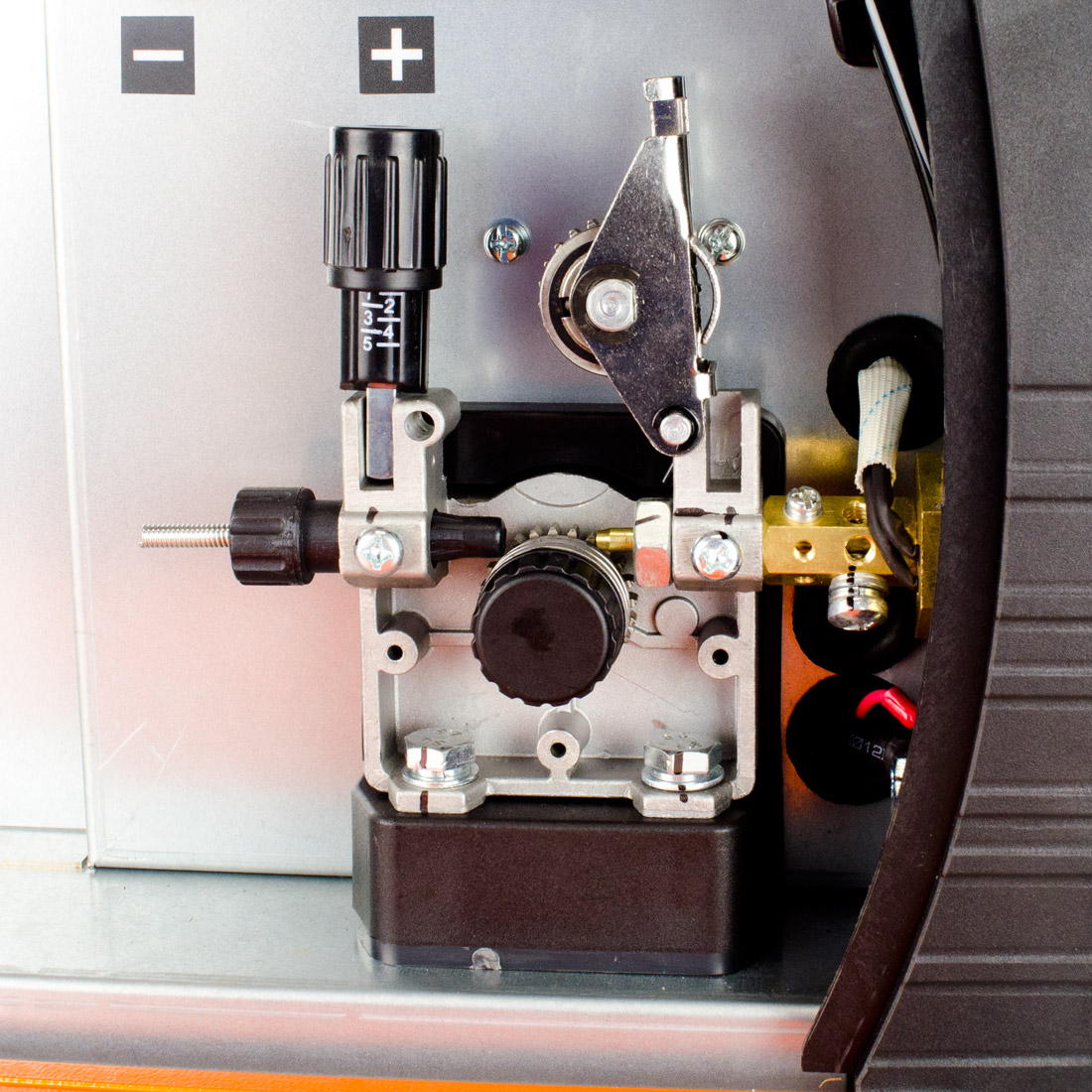

At this point my preference is a Jasic MIG 160 which is sold for about € 500 with a 5 year warranty. I first came across the MetalWorks MIG 160E but it looks like a Jasic MIG 160 and it is more expensive and has only 1 year warranty.

There is also the option of an EVO MIG 160 Multi Synergic at around € 620 (and an additional € 50 for a TIG torch) that has caught my eye... A Jasic MIG 200 Synergic is about € 799.

However, I've been pushing the upper limit of the budget (as I started by looking at a € 399 rebranded Punair MIG 200 Synergic) and it looks like it won't stop if I don't make a choice soon.

Questions:

Niels

I do have access to a TIG welder (my father-in-law is the son of a retired welding supplies dealer), but after reading and researching it seems that a MIG with a low "starting current" combined with 0.6 mm wire is the way to go for thin sheet (0.8 mm).

I've been searching a lot and trying to read as much as I can about different options. Mind you that I don't live in the UK and it seems that not brands are distributed at this side of the Channel.

At this point my preference is a Jasic MIG 160 which is sold for about € 500 with a 5 year warranty. I first came across the MetalWorks MIG 160E but it looks like a Jasic MIG 160 and it is more expensive and has only 1 year warranty.

There is also the option of an EVO MIG 160 Multi Synergic at around € 620 (and an additional € 50 for a TIG torch) that has caught my eye... A Jasic MIG 200 Synergic is about € 799.

However, I've been pushing the upper limit of the budget (as I started by looking at a € 399 rebranded Punair MIG 200 Synergic) and it looks like it won't stop if I don't make a choice soon.

Questions:

- Is it worth investing in a synergic if I'm not sure I will do a lot of TIG? I will not be investing in 2 gas bottles and I do have access to a pro level TIG only a few blocks from my home.

- Is there any other benefit of a synergic except for the additional TIG support?

- How much of a benefit are those LCDs on the welder?

Niels

I'm sure mine will not be different as it has been neglected for about 8 years. I'll start by taking out the engine and dismantling the rest of the "drive train". The body will stay as long as possible on the old chassis while I rebuild a new one based on a galvanised chassis. The body work will be the last part of the journey (and will probably take the longest). I will be assisted by a friend who has been a coachbuilder (this is how Google translates "carrossier" from Dutch) at a Citroën garage for over 10 years. I was planning on using replacement parts as I don't have any tools to bend/form sheet metal. But this is all in the future, so we'll see how it goes. It will never go as planned.

I'm sure mine will not be different as it has been neglected for about 8 years. I'll start by taking out the engine and dismantling the rest of the "drive train". The body will stay as long as possible on the old chassis while I rebuild a new one based on a galvanised chassis. The body work will be the last part of the journey (and will probably take the longest). I will be assisted by a friend who has been a coachbuilder (this is how Google translates "carrossier" from Dutch) at a Citroën garage for over 10 years. I was planning on using replacement parts as I don't have any tools to bend/form sheet metal. But this is all in the future, so we'll see how it goes. It will never go as planned.